Here’s a photo a colleague of mine from ISA Drive forwarded on to me. ISA is KEB’s Lift partner in Germany and they run across a lot of older KEB elevator drives in the field.

The VFD in the picture is KEB’s F2 inverter. The F2 was private-labeled for the Siemens Elevator group back in the day. This particular inverter was installed in 1994 and continues to run great today. That’s almost 30 years of operation in what is generally considered a very difficult drive application.

It brings to mind a question that I often get asked, “How long can I expect my VFD to last?” I would respond, “It all depends.” There are a lot of factors that come into play when talking about a VFD’s expected lifetime.

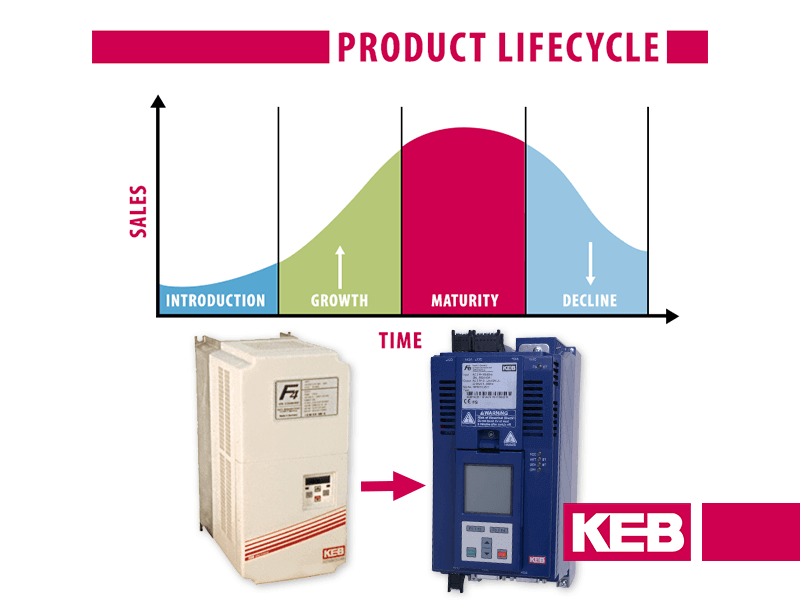

Most manufacturers will admit the typical life expectancy is 7-12 years, but there are many factors at play.

VFD components like fans and capacitors have a finite life and starting at about 5 years, these components can start to fail and will need to be replaced.

Having said that, there are a number of different factors that come into play. Correctly planning and applying the product will play a big factor.

The Product

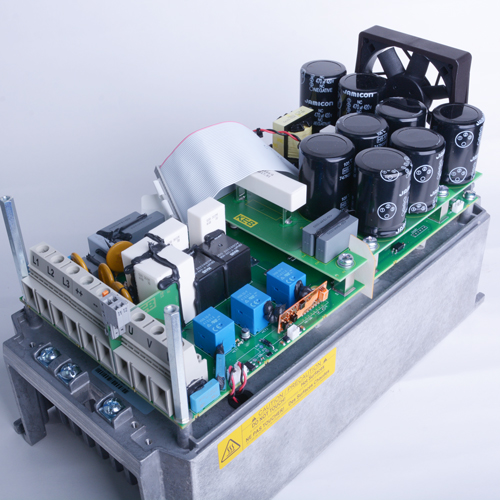

The first thing that comes to mind is the product itself. What is the quality of the overall design and integration of components? Does the drive have internal design safety factors and overloads? What is the quality and size of the components? A chain is only as strong as the weakest link. If the drive is designed with an undersized input stage, output transistors, or bus capacitors, then those will be a point of common failure.

Are there hardware and software-based protective features which protect the drive from catastrophic failure? The protective features should cover the different failure scenarios (overvoltage, overcurrent, overheat, etc.). Not only does the drive have the protective factors, but are they enabled, and have they been programmed to properly protect the drive. In many cases, the default drive settings will not have these protection parameters enabled.

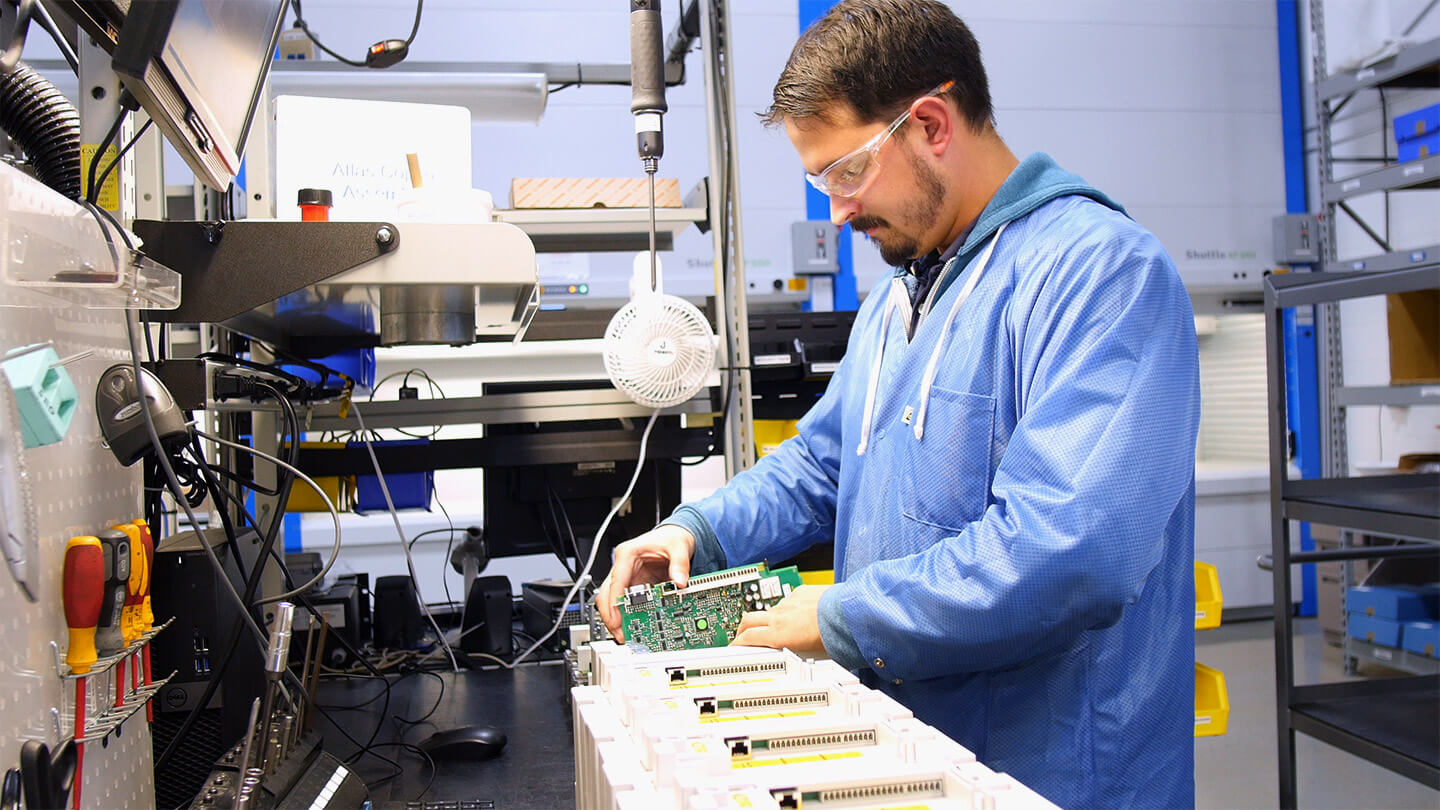

And was the product rigorously tested before it left the factory? Or does the manufacturer simply assemble, maybe do a quick function test, and ship out? For example, KEB drives are tested under varying loads in a heat chamber for an extended period of time. This type of testing isn’t cheap but it ensures the drives are stress tested before they get into the field.

KEB drives are tested under varying loads in a heat chamber for an extended period of time.

The Environment

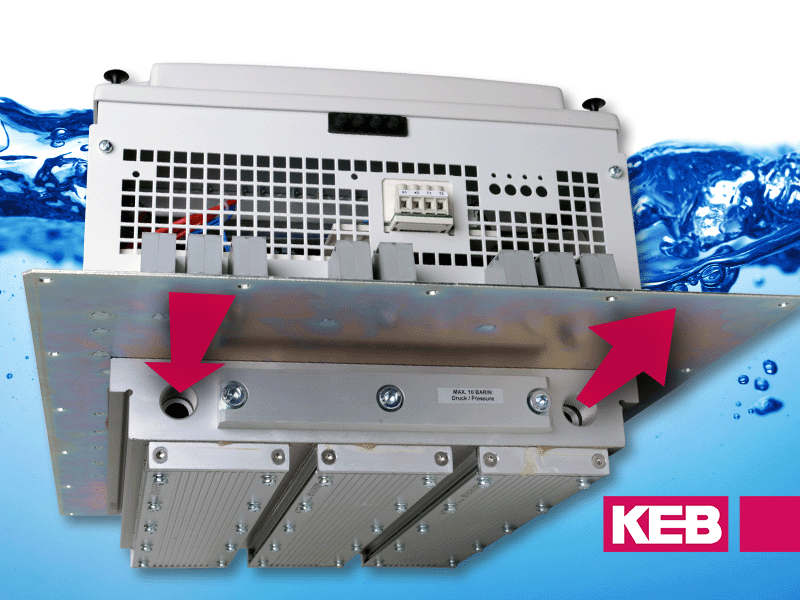

The environment has a lot to do with a VFD’s lifetime. Heat is the enemy – Is the ambient temperature within the manufacturer’s recommendation? Or is the drive placed in an exposed panel in the middle of the desert with no A/C? Are there fibers or particulates in the air that could potentially clog the VFD fans, and thereby increase the drive’s temperature? KEB offers liquid-cooled VFDs which work great in areas with a lot of contaminants in the air. There are no fans or heatsink fins to become clogged.

Sounds crazy but is there water or moisture around? – water and power electronics don’t mix well. Are there corrosive gases present that could eat away at the circuit boards or components? Are there metallic shavings due to nearby construction or electrical panel work that could short out internal components? These factors cause immediate failures that are usually catastrophic.

The Application

The other factors relate to if the product is applied correctly. You can have the best product in the world but it won’t last if it’s not being used correctly. Is the VFD sized correctly for the application – including momentary overloads? Have the protective functions been activated and are they programmed correctly?

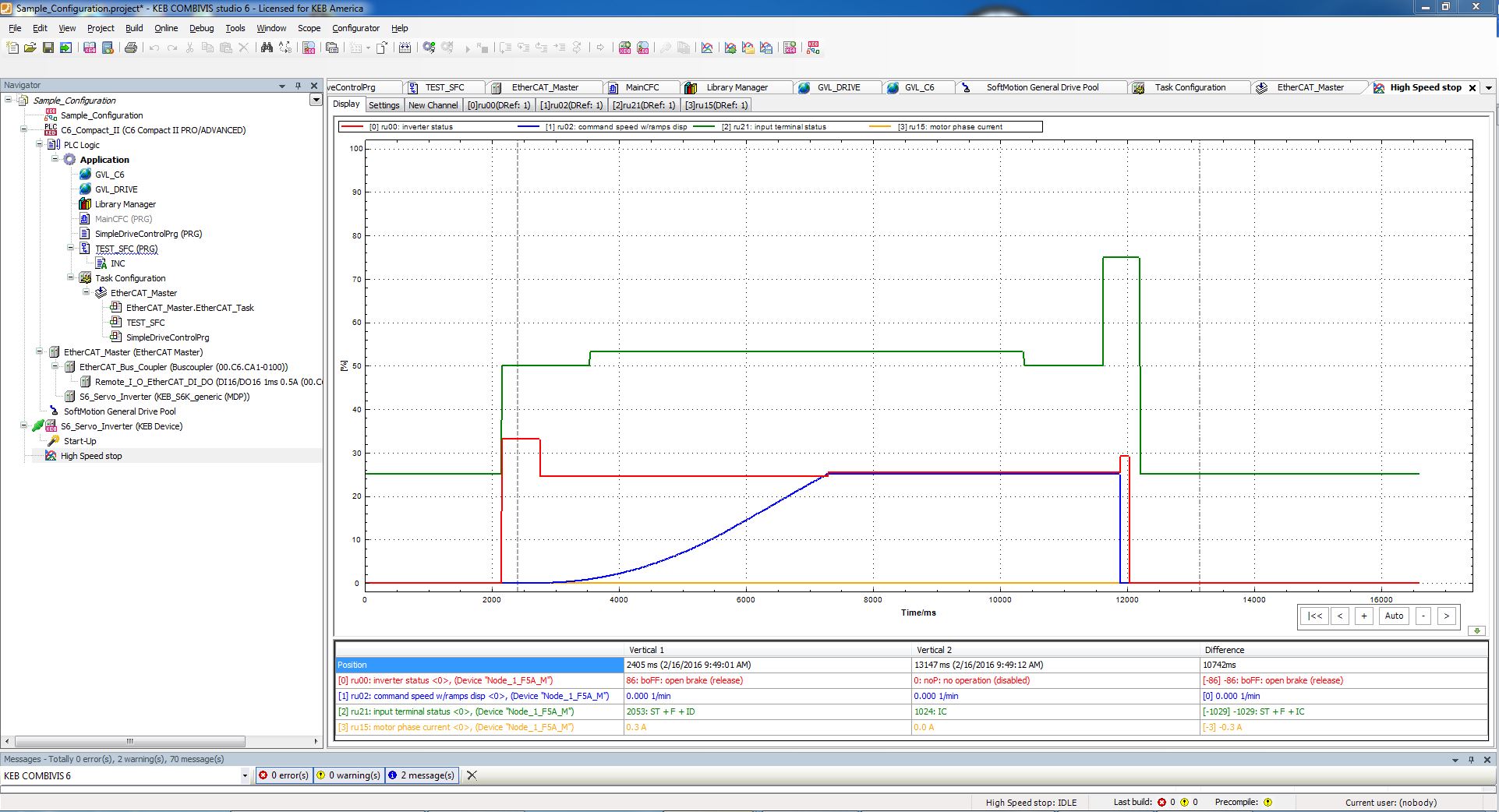

Has the inverter been programmed correctly to allow for the lowest possible currents and heating? For example, if a VFD’s brake timings are not adjusted correctly it could result in an excessive current overload during each start/stop cycle as the motor runs through the brake. In addition to a lot of brake wear, the drive lifetime will be shortened.

When possible, the VFD should avoid very stressful errors and conditions like overcurrents and overvoltages. If a VFD is subjected to many of these stressful events, then the chances of a component failing increase substantially. So it is advised where possible to avoid shorts in the electrical system and protect the control panel from events like a lightning strike.

VFDs – Invest Now and Have Many Years of Operation

So if you want my recommendation for selecting a VFD for longevity:

- DON’T base your choice solely on the lowest upfront cost

- DO start with a good quality product from a reputable manufacturer

- DO choose a partner who thoroughly understands their own product and how to apply it correctly in your application/environment

For more information, contact a KEB America engineer.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.