Benefits of VFDs and line-regenerative units for escalators

This article originally appeared on www.kebamerica.com as a three-part series and was featured in the May 2018 issue of Elevator World magazine.

Variable-frequency drives (VFDs) paired with line-regenerative units are a great fit for escalator applications. Compared to line-fed escalators, VFDs provide maximum application performance benefits, such as smooth speed profile ramps, adjustable torque limits and drive modes based on user traffic. Thanks to its power factor (PF) improvement, a VFD will also reduce large inrush currents and power consumption. Compared to braking resistors, a line regenerative unit can provide energy savings in overhauling applications (i.e., downward-traveling escalators) and provide a reduction in both heat generation and controller cabinet size.

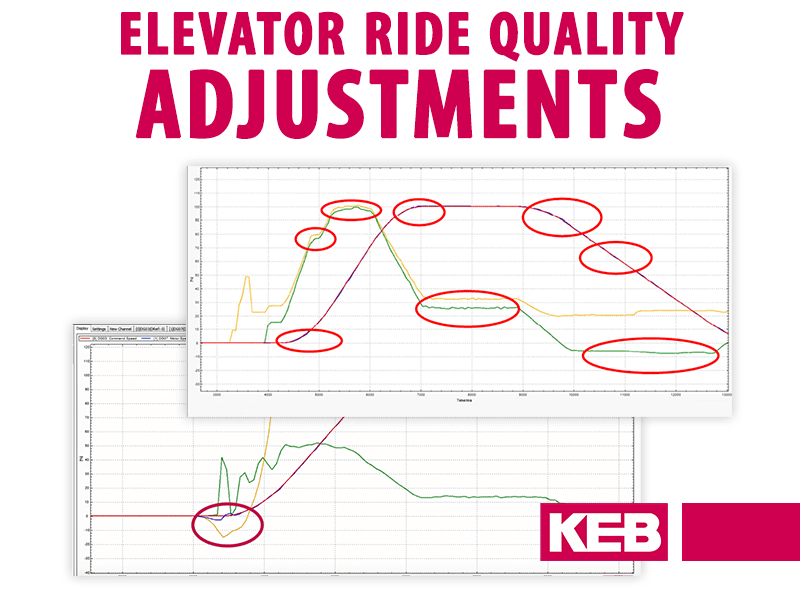

The VFD features parameters that can be tailored to the escalator application for easy setup and adjustment . Adjustable S-curves are available to provide smooth ramp-up and ramp-down speed profiles. Smooth profiles limit inrush current at turn-on, prevent excessive wear and tear on mechanical components, and provide a comfortable ride for passengers. Adjustable torque limits can also be set to help protect mechanical components from being stressed because of a jam or other critical safety events.

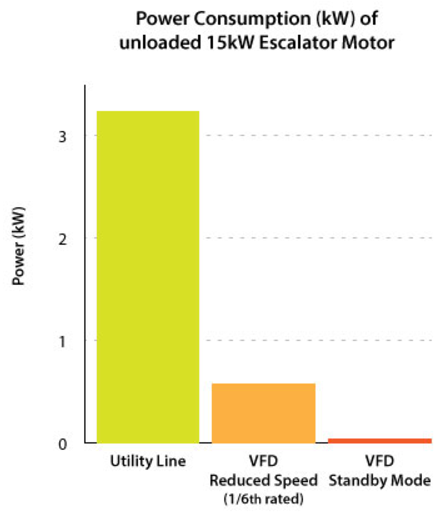

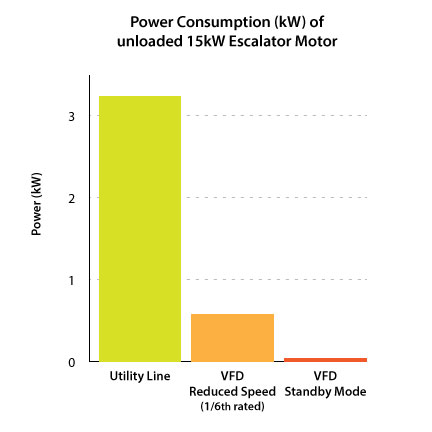

]Depending on the installation, some escalators may go long periods of time with little or no load. During these periods, it is possible to reduce the speed of the escalator motor to save energy. Reduced-Speed Mode can be set to lower the speed of the escalator motor after a defined amount of time. For example, when an escalator has operated unloaded for 10-15 min., the VFD can reduce the speed of the escalator motor to 20-50% of rated speed. The VFD continues to operate in reduced speed mode until an approaching passenger is detected by a light curtain or pressure mat. The VFD then smoothly ramps the motor up to rated speed. Figure 1 shows the energy-saving benefits of using a reduced-speed mode in an escalator application featuring a 15kW induction motor in various control modes. The largest incremental savings result from using a VFD to operate the motor at a reduced speed during periods of inactivity.

Both open- and closed-loop control modes are available when using a VFD. KEB offers an enhanced control mode, Asynchronous Sensorless Closed Loop (ASCL) for applications that wish to run open-loop but would like performance characteristics similar to closed-loop applications . ASCL uses a control algorithm based on the motor data to automatically measure and model the motor characteristics without encoder feedback . This provides excellent control in both stable and dynamic motor operation, accurate speed control and high-speed stability without the added cost and complexity of an encoder. In addition, both closed-loop and ASCL control modes offer PF improvement compared to line-fed or open-loop-controlled escalator applications.

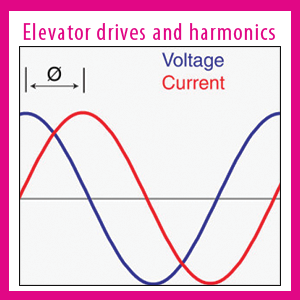

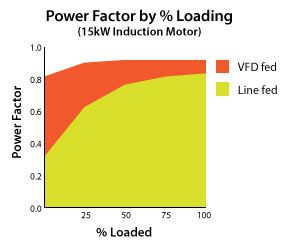

The PF is a unitless number that represents the ratio between the power being put into useful work (measured in watts) and the total electrical power being transferred (measured in volt-amps). A unity PF of 1 is ideal and indicates all power being delivered is being usefully consumed by the escalator motor. Figure 2 shows the benefits of using a VFD compared to a line-fed induction motor. The most noticeable benefits will be when the VFD is in closed-loop or ASCL operation and when the motor is partially loaded – a scenario common in many escalator applications.

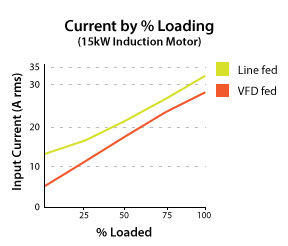

However, even when the motor is at full load, the PF is improved by 10% when using a VFD. Line-fed escalators experience high starting currents – sometimes as high as 500-700% of motor rated current. As illustrated in Figure 3, a low PF will also contribute to a higher input current for a given amount of power output at the motor shaft. Again, the largest benefit is realized under partial load. In this case, the no-load RMS current with a VFD is more than SO% lower than that of the line-fed motor. This higher input current should be avoided, because it requires electrical components to be oversized to accommodate the transfer of unused reactive power. Also, there will be more resistive conductor losses due to the transfer of the additional reactive power. Finally, a low PF will cause higher heating in electrical components, which can lead to reduced operating lifetime.

Regenerative drives are great candidates for overhauling escalator applications in which the induction motor is acting as a generator. Traditionally, braking resistors were used with VFDs to dissipate the regenerated energy as heat. Depending on the braking resistor location, the extra heat produced may require additional cooling or a larger controller cabinet. This could cause problems when designing the escalator control panel, if space is at a minimum. As an alternative to braking resistors, a line regenerative drive (pictured right) can be connected to the VFD through a DC bus connection. The regenerative unit operates by measuring the line voltage and frequency. Once the DC bus voltage exceeds a predetermined threshold, the drive modulates, allowing current to flow back to the line, where it is consumed by other electrical loads (e.g., in the building or installation). Depending on the application, a regenerative drive can be expected to pay for itself, reduce overall power consumption and provide net cost savings over its operational lifetime.

Escalator applications with high gravitational potential energy (e.g., high-capacity escalators moving many people with long downward travel distances) make great candidates for line regeneration. Gravitational potential energy can be described by the equation:

Gravitational Energy = mass x gravity constant x height of travel

Typically, these larger escalators will be in the 20-hp-plus range. Other factors that will impact line-regenerative payback are escalator drivetrain efficiency and the usage profile. High-efficiency (greater than 90%) helical or bevel gearing is ideal. Low-efficiency (less than 60%) worm gearing provides significantly less savings due to a sizable amount of energy being lost in power transmission. The amount of traffic on the escalator and the duty of the escalator will also impact returned energy savings. Subway stations and airports conveying many passengers and operating 24/7 are ideal and provide the best payback.

VFDs give escalators a performance advantage through low starting current, motor PF improvement and reduced energy consumption. They also provide smooth S-curves and adjustable torque limits for ride quality and safety benefits. Line-regeneration units help save energy and reduce control-cabinet space in overhauling escalators, while cutting down on additional heat generation caused by braking resistors. Used together, VFDs and line-regeneration units can add significant value to escalator applications.

If you have a question about our elevator or escalator solutions, fill out the Contact Us form.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.