VFD Technology for Running High Speed Gearless Turbo Blowers

What are the most important factors when considering VFD Technology for Running High-Speed Gearless Turbo Blowers? Here at KEB, we like difficult applications because this is where we excel and where our technology and application engineering differentiate us from our competitors. These applications could require multiple axes of coordinated motion control or be located in challenging environmental conditions. Operating a high-speed motor/generator is one example of a difficult drive application.

One high-speed application that KEB has extensive experience in is running gearless turbo blowers. This post gives an overview of KEB’s VFD offering and reasons why KEB is the partner of choice for turbo blower manufacturers worldwide.

High-Speed VFDs

First off, what do we mean by “High Speed”? The best definition is the one that is used by the US Department of Commerce. Outlined in regulation ECCN 3A225, drives operating 600Hz and above are considered high speed.

High-speed applications are very demanding applications for VFDs. They require extremely stable motor control algorithms with very fast control loops. I use the analogy of skateboarding. I am not very good at skateboarding, but I can stand still on one. I can go forward slowly and still remain in control. I can even correct from some small obstacles like a crack in the road or rough pavement. This is comparable to normal low-speed VFD applications where the drive can control the motor and correct from dynamic load requirements.

High-speed applications allow less room for error

However, if you were to put me on a steep hill and I were to go very fast, the end result would not be good. I would likely begin to lose control, then try to correct myself, overcorrect, and crash. This is like a high-speed motor application – there is less room for error on the control stability. Any small load transient acts like the crack in the road or the rough pavement and can cause the control system to become unstable.

A company does not develop high-speed motor control algorithms overnight. KEB’s high-speed drive products represent decades of motor control engineering. And that is evident in the over 100,000 high-speed applications that are running in the field across a wide variety of power ranges and motor types.

Dedicated High-Speed Power Stages

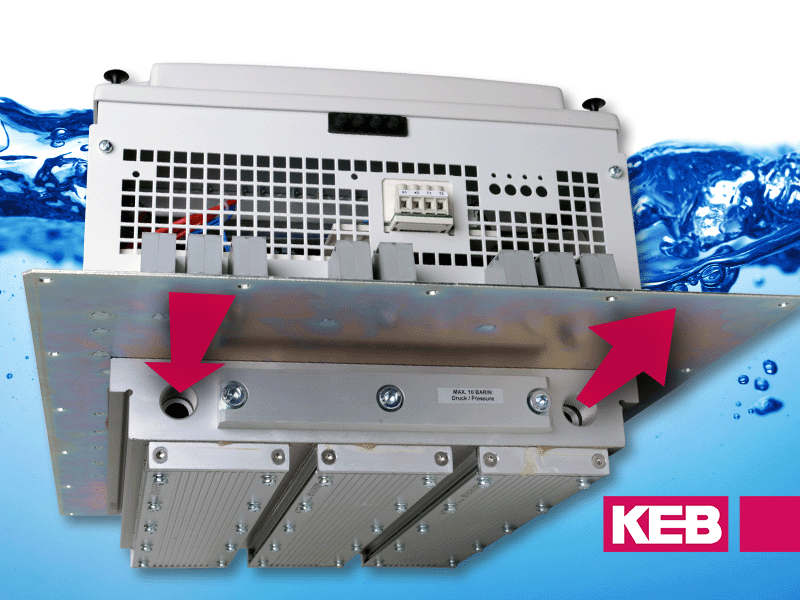

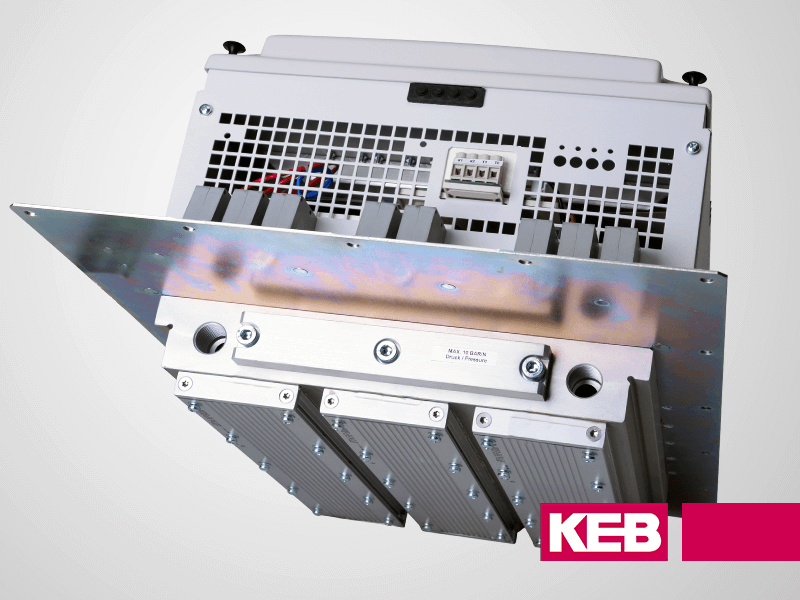

The VFD power stages used in high-speed applications are also unique, especially at high power (200Hp+). The IGBTs must be capable of switching at a very high frequency – usually 8kHz or 16kHz. The higher switching frequency causes more heating and the power stages must be designed specifically for that use.

Air cooling these large IGBTs with high frequency can be challenging if not impossible. So KEB also offers liquid-cooled drives which are particularly effective at cooling the large high-speed VFDs.

3C3 Protection for Corrosive Gases

Some high-speed blower applications in the wastewater industry are exposed to corrosive gases. This is particularly true for high humidity environments where gases like chlorine, ammonia and hydrogen sulfide can corrode the drive’s components and connections. Ultimately, this can lead to complete drive failure. For these applications, KEB has developed a special protective board coating to address these conditions. Specifically, this is designed to IEC/EN 60721-3-3 class 3C2.

KEB F5 3C3 Part Numbers

- 19F5E0R-Y0F4

- 20F5E0R-Z04F

- 21F5E0R-Z04F

- 22F5E0R-Y04F

- 23F5E0U-Z04F

- 26F5E0U-Y04D

- 28F5E0U-Y04H

- 28F5E0U-Y04D

- 29F5E0W-Y04H

- 29F5E0W-Y04D

- 30F5E0W-Y04D

- 30F5E0W-Y04H

- 32F5E0P-Y04H

- 33F5E0P-Y04H

Commercial Drives vs. R&D Drives

An important differentiator in this application is KEB’s large installed base and the fact that the product is part of our standard F5 and F6 product lines. Some high-speed drives being used are not really commercial products. They are more like lab or R&D projects. These have no UL certification, no documentation, etc. KEB’s high-speed drives are all UL listed, with up-to-date documentation which makes the final blower product easier to install and support.

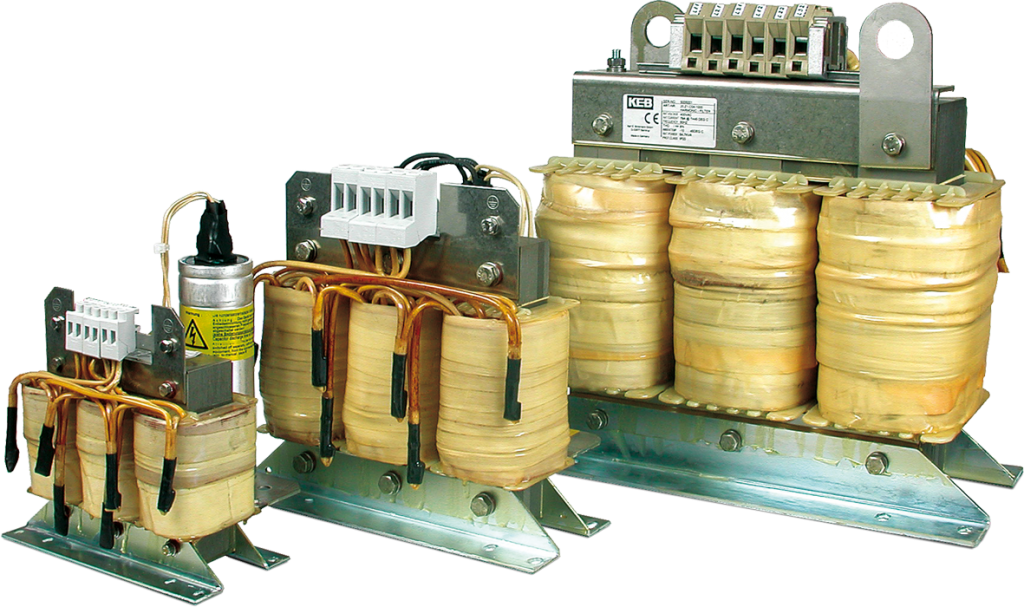

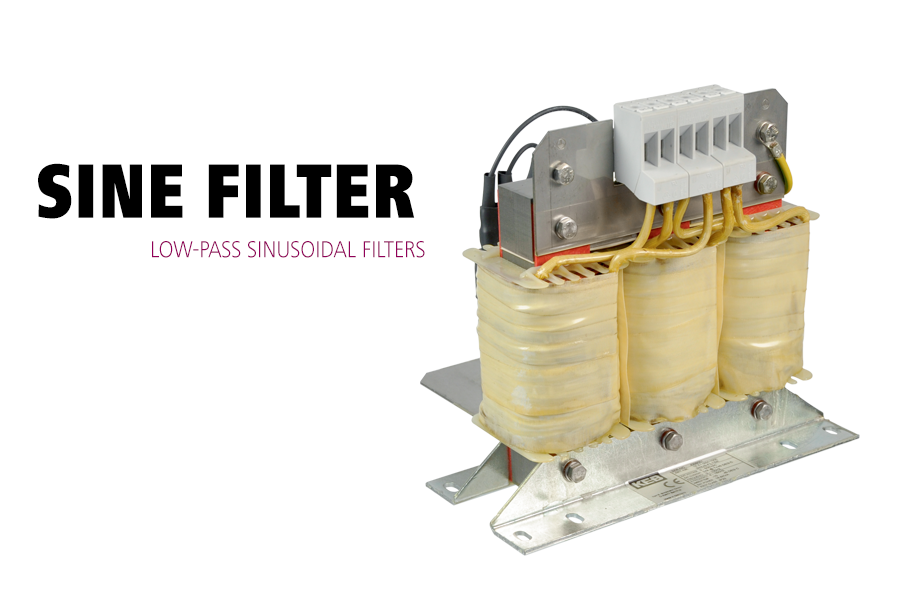

Filter Technology

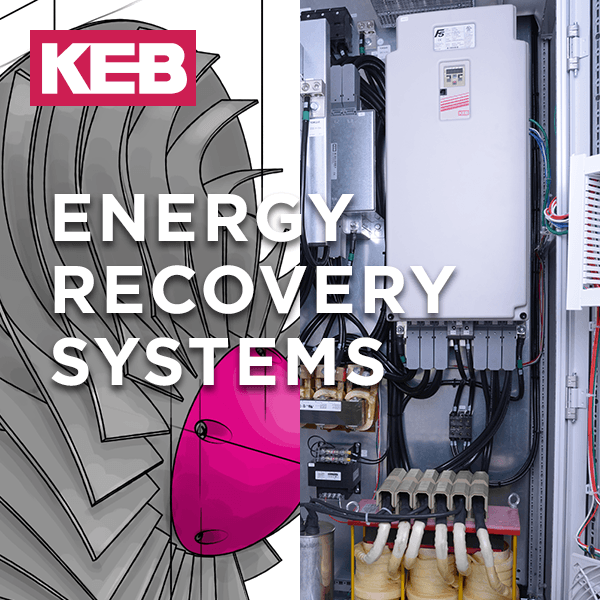

A critical part of KEB’s drive offering is our compliment filter technology. KEB offers a variety of different filters that include Harmonic Filters, EMI filters, and Sinewave filters. Harmonic filters can be used in Blower applications if IEEE 519 requirements need to be met.

Sinewave filters can be very advantageous to the motor-drive combination because they deliver a near-perfect sinusoid waveform to the motor which reduces motor heating and ultimately allows the motor to output more usable power.

Conclusion

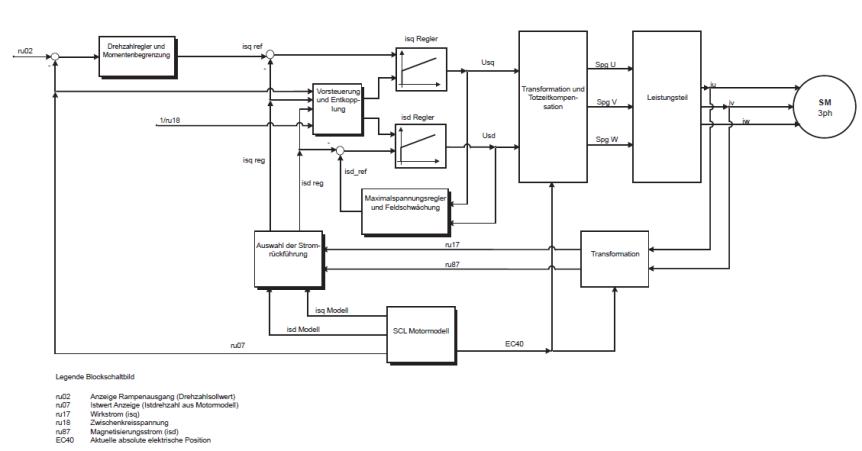

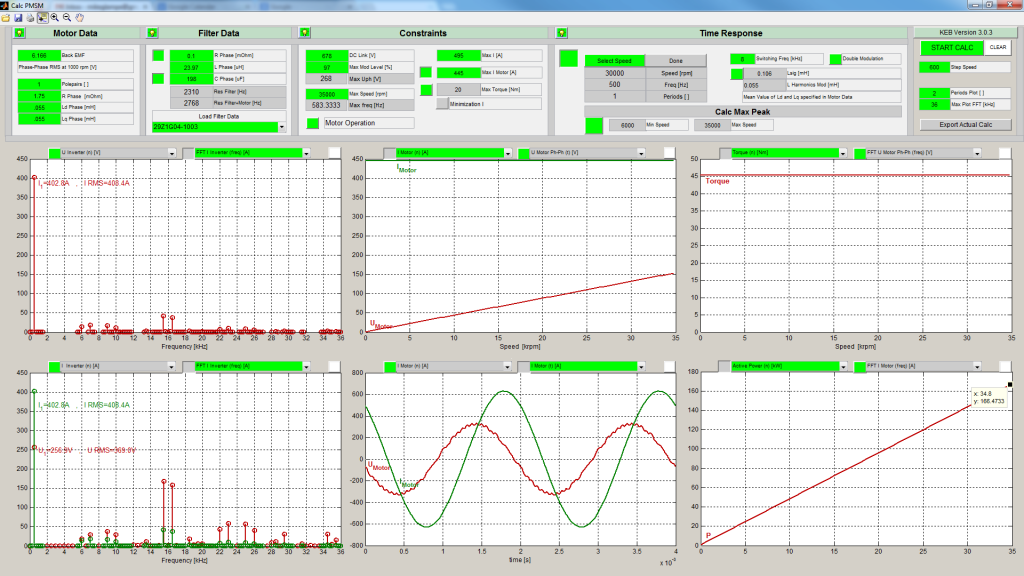

Because KEB has engineered both the filter and drive technology, we have become an important solution partner instead of a component supplier. This is best shown by our ability to run powerful control simulations that approximate the performance of the filter VFD motor. These simulations can be run very quickly compared to months of iterative testing.

Do you have a high-speed turbo or compressor application to discuss? Speak with a KEB application engineer today to discuss.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.