VFDs for High-Speed Compressors: 5 Things You Should Know

Many engineering advancements provide small incremental efficiency, cost, and functionality gains. However, some engineering milestones provide giant leaps of improvement. Once commercialized, these are “game changer products” that can help redefine entire industries.

Centrifugal turbo compressors and blowers are one such development. They offer double-digit efficiency gains compared to positive displacement and multistage centrifugal compressors.

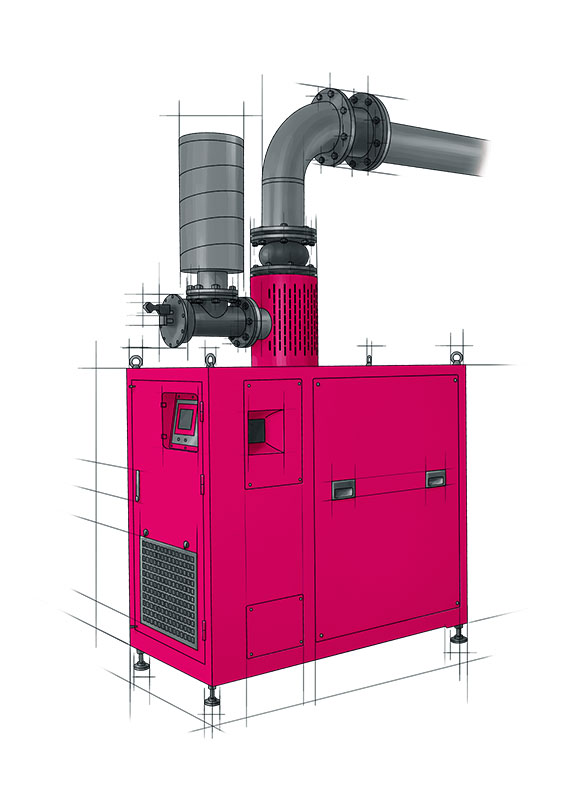

At the core of the technology are a high-speed motor, a high-speed VFD to control the motor, and special bearings capable of supporting the motor over 20,000 rpm.

With over 100,000 high-speed installations globally, KEB is a leading provider of high-speed drive technology for compressors and blowers. This article describes some considerations when designing a high-speed compressor system.

1. The Use of a Special High-Speed VFD

The VFD used to control the high-speed motor must be capable of a high-frequency output. KEB offers drives that output up to 2000Hz, which equates to 120,000 rpm, with a 2-pole motor design.

Most standard off-the-shelf drives cannot do this for many reasons. First, they lack the correct IGBTs and power stage hardware capable of high-frequency switching. This is especially true at the large current ratings that commercial turbo compressors need.

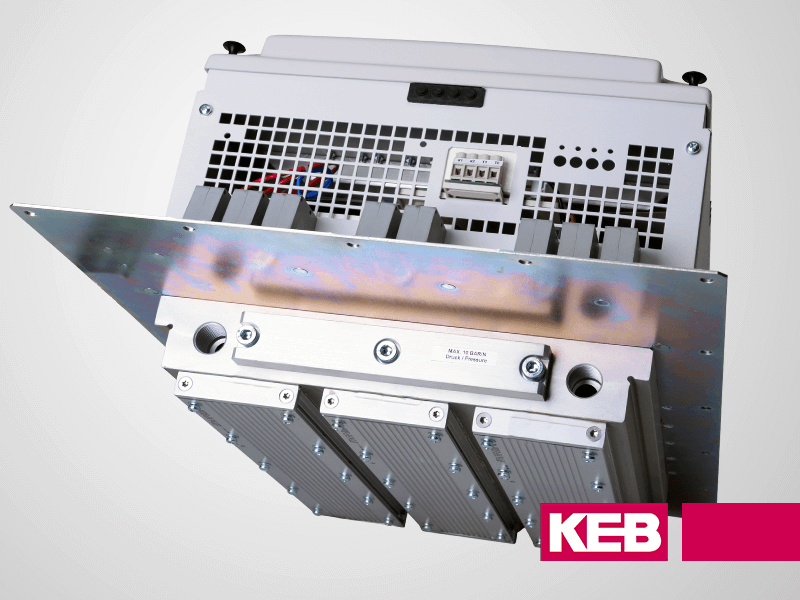

Second, high-frequency switching of the IGBTs will create a lot of heat, which must be designed for. KEB has developed unique heatsink solutions that handle this increased heating. This includes liquid-cooled VFD heatsinks that can be quite advantageous for large-current, high-frequency applications.

Finally, simply providing a basic V/Hz output might not yield the best results – as measured by the motor temperature and control stability.

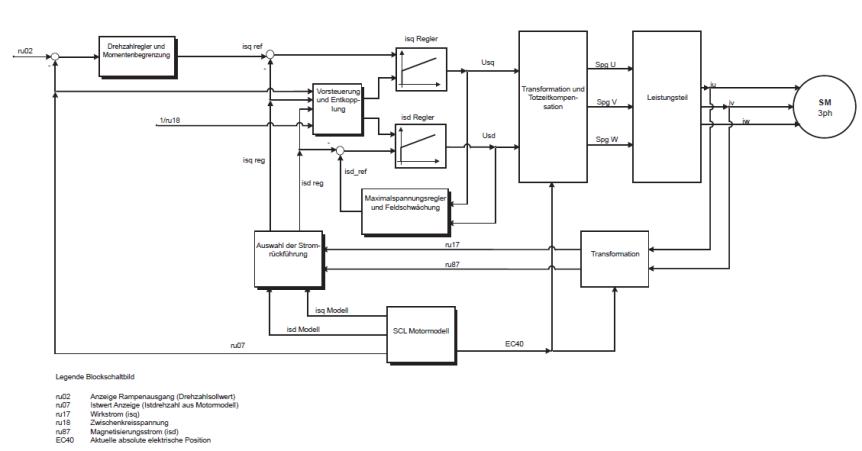

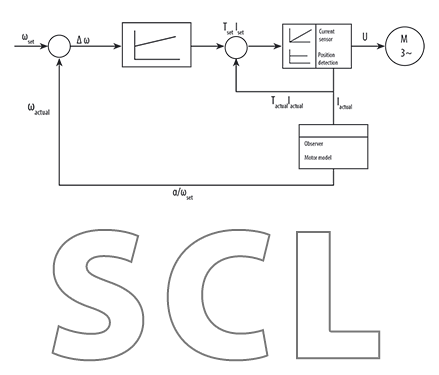

KEB often uses our proprietary SCL control software for high-speed applications, providing exceptional torque and rapid response at high speeds. SCL also provides excellent control stability across the entire speed range. This is a prime example where customers benefit from KEB’s many years of motor control algorithm know-how.

Learn how KEB helped Piller Blower & Compressor in their high-speed development.

As a side note, the US Bureau of Industry and Security and other governments define “high speed” as a VFD capable of 599Hz and above. These high-speed VFDs are a controlled product since they are a critical technology in specific nuclear processes. Off-the-shelf products will likely be rated at 599Hz or less. Special high-speed VFDs are capable of higher output frequencies that often need to be “unlocked” — and come with a controlled part number.

2. A System View Approach

The high-speed motor and drive should always be viewed together as a system. Changing the parameters of one likely affects the other.

Hypothetically, if you want the same speed, changing from a 2-pole motor to a 4-pole motor means the drive output frequency must double. Doubling the output frequency of the VFD likely means the drive must be upsized to handle more internal switching losses. Like many things in engineering, there are tradeoffs to be considered.

A common goal in any high-speed development is to reduce motor heating. A motor that runs cooler will have a longer operating lifetime. A cooler running motor will also increase the operating lifetime of the critical and expensive airfoil or magnetic bearings.

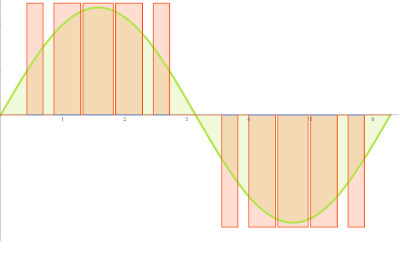

KEB also offers our line of Sine Wave filters that can be paired with our drives. The benefit of a Sine Wave filter is that it filters the high-frequency PWM output and provides a low harmonic sinusoid waveform to the motor windings. Our motor partners typically use Sine Wave filters because it reduces the motor temperature at a given power output. Again, lower motor temperatures have long-term benefits for motor and bearing lifetime.

3. Choose a Drive Partner to Help with the Development

Developing a high-speed turbo blower involves experts in each discipline. This might include the impeller design expert, the bearing expert, the motor expert, and the drive expert.

KEB brings several things to the table when we can help early in the design process. First, we can assist an OEM in understanding the tradeoffs between motor and drive. For example, we can clarify the system tradeoffs with design changes (e.g., changing motor pole pairs, induction vs. PM motor, air vs. liquid cooled). A better understanding early in the design process will help to design a product that meets the OEM’s target goals.

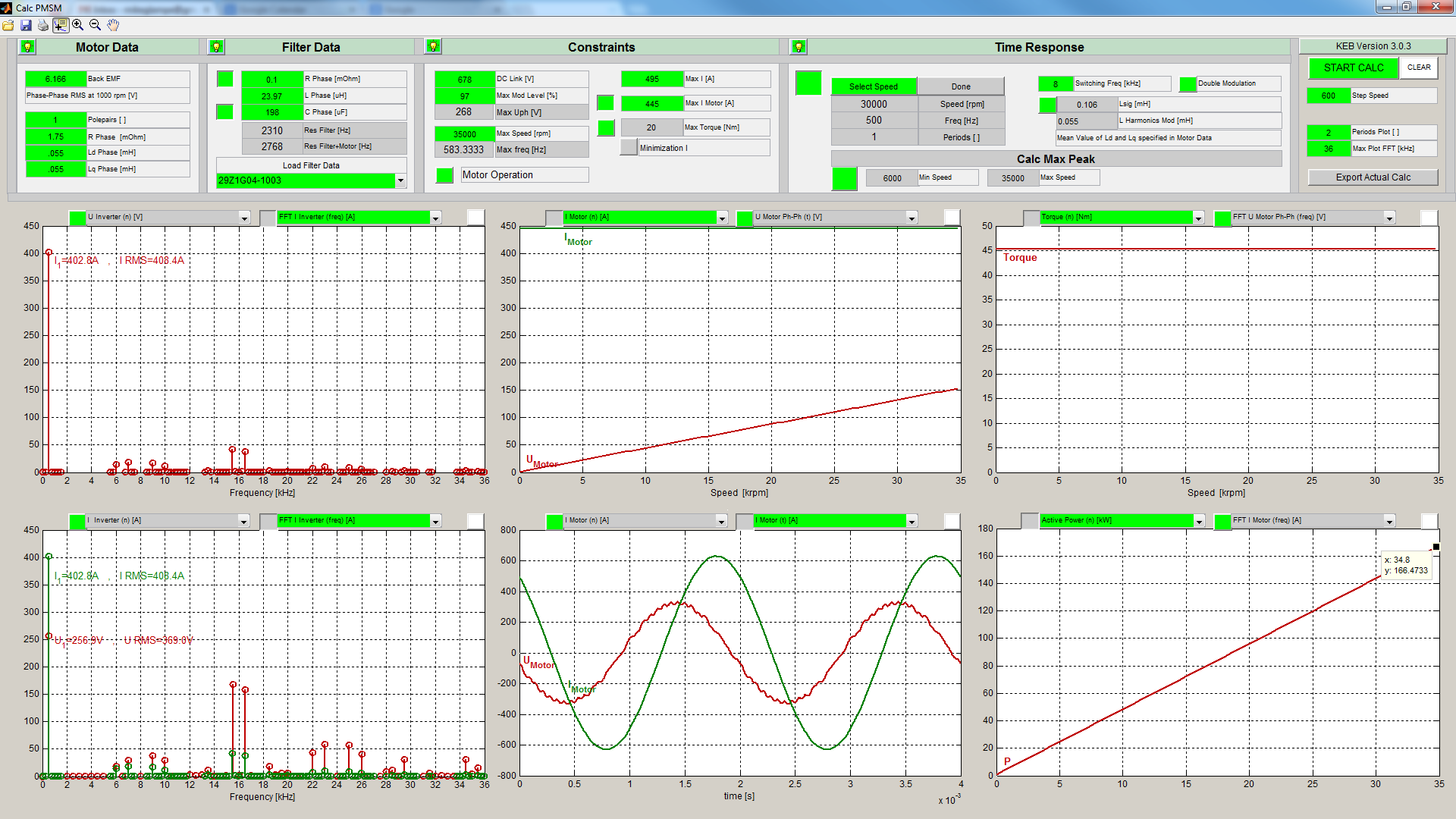

One powerful tool that KEB uses is our HIL simulation program. HIL stands for Hardware in the Loop, allowing us to run simulations on actual control card hardware. The net result is that we can get very accurate simulation data – 99.9% correct – without ever setting foot in a test laboratory. These simulations offer valuable insight into which motor, drive, and filter selections are needed to achieve the required output.

4. North American + Global Production and Engineering

Our North American partners are glad that the KEB technology and application engineering knowledge is located at our facility in Minnesota. Our high-speed drives are manufactured here in our ISO 9001:2015 production. Because our drive products are assembled here in the U.S., we can help comply with Made in America or Buy American requirements.

What happens if you are not located in North America? KEB has similar application groups that focus on high-speed applications worldwide. Production plants in Europe and China mean that KEB can accommodate global development and support high-speed applications worldwide.

5. Choose a Commercially Viable Product

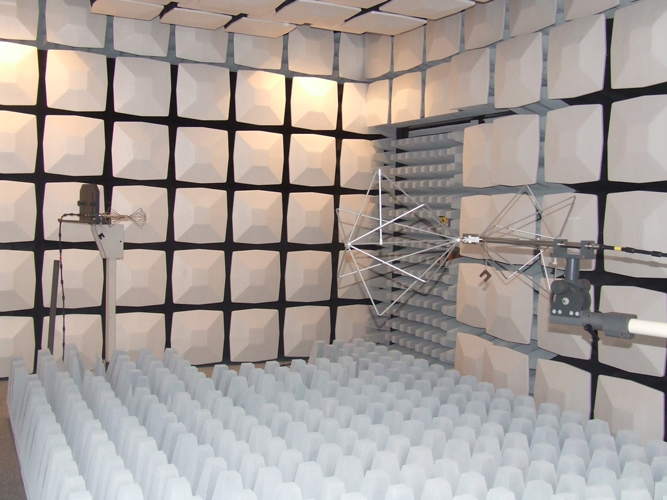

Developing and testing a high-speed drive in a laboratory setting and rolling out a commercial product worldwide are two different things. A commercial product will benefit from choosing components thoroughly tested for EMI and safety. These electrical components should carry certifications like UL, CSA, and CE, making the compressor easier to test, certify, and bring to market.

Compressor manufacturers will also benefit from choosing high-speed VFDs assembled and tested using automated processes and test cells. Complete traceability with serialization is another essential factor in providing the best quality at a large scale.

KEB – A Valued Partner in your Development

Contact KEB America early in your design process if you plan to start the development of a new high-speed compressor or blower product. Leveraging KEB’s decades of high-speed VFD experience will save time and money.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.