VFDs for High Vibration Environments

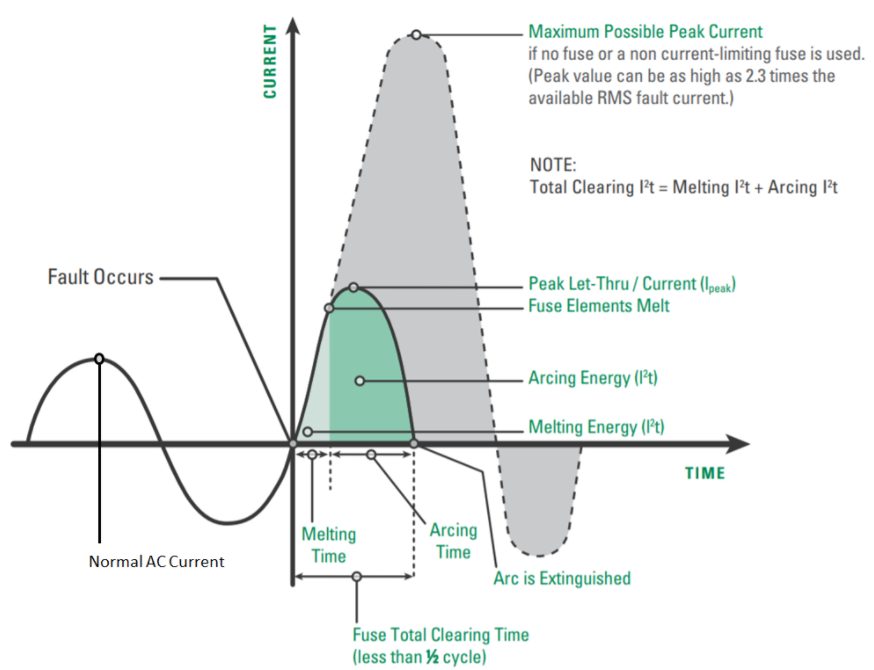

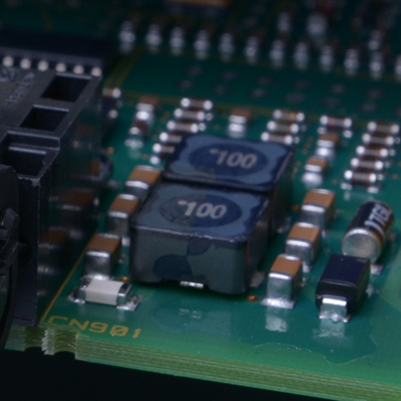

Generally speaking, VFDs are not designed to withstand high vibration environments. Most drives are considered industrial grade, not aerospace or military grade. VFDs feature many different components, solder joints, standoffs, and connectors. The designs and components are chosen to balance cost and performance but especially cost. If there is little to no vibration, the drives will perform just fine. However, if exposed to excessive vibration, these joints and connectors will fail prematurely.

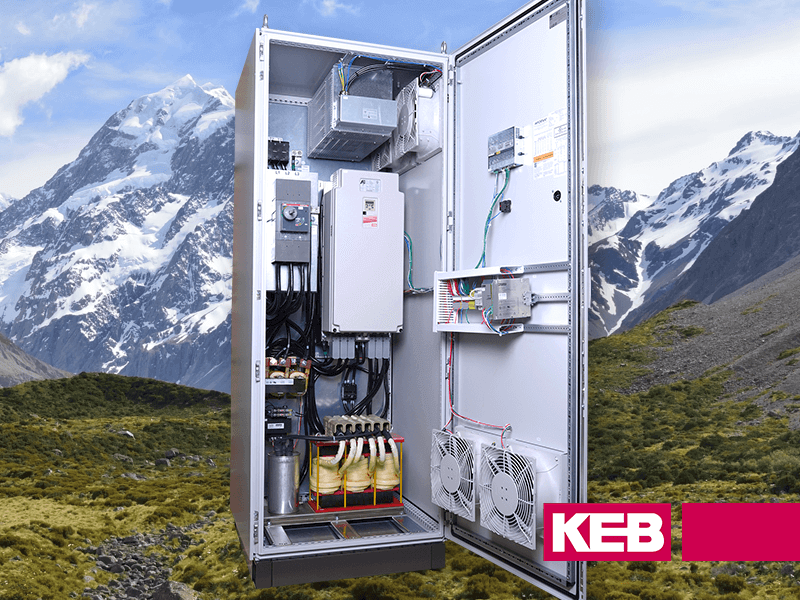

In some applications, vibration cannot be avoided. Applications like AGVs, wind turbines, auxiliary drives for buses, and material handling machinery come to mind. Some external measures can be taken to try to dampen the vibration of the panel like vibration isolators. But using a rubber isolator can introduce other issues like EMI noise and poor grounding. The other option to address vibration is to look at the construction of the VFD itself.

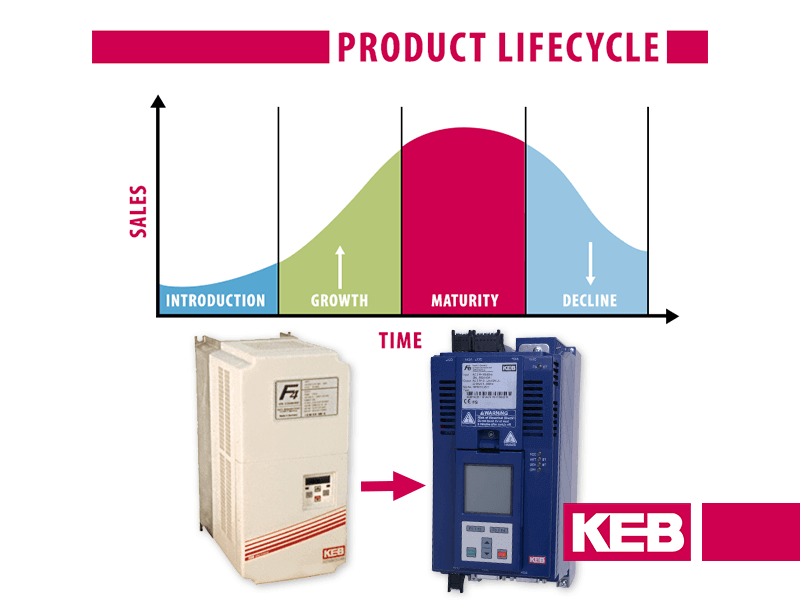

KEB’s standard offering – EN 60721

All KEB drives are designed and tested to meet different EN vibration specifications for operation, transport, and storage. For operation, KEB drives are designed to meet the Vibration levels called out in EN 60721-3-3 class 3M1.

Special applications require special solutions

At KEB, we do not think one size fits all. We try to understand our customer’s application and what is needed and offer the best solution to the problem. This has led us to a number of “Special” solutions like liquid cooled drives, push through heatsinks, and vibration resistant drives.

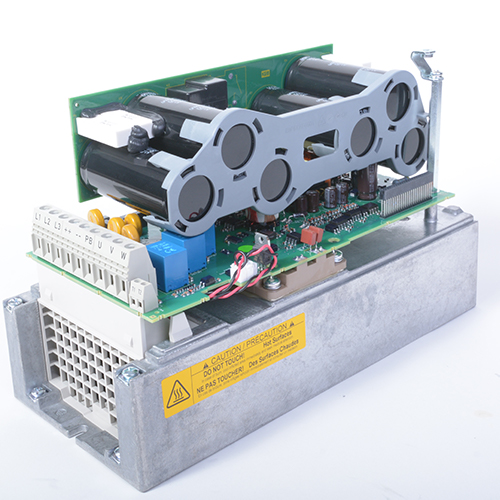

We also offer the T6 Auxiliary Inverter that is designed from the ground up specifically for the automotive industry. This drive is ideal for commercial electric vehicles and emobility applications.

When needed and applied correctly, these solutions are great and lead to a better and longer performing machine. One of these ad hoc designs is an inverter for higher vibration applications.

Get more information about VFDs built for high vibration environments by contacting a KEB application engineer today.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.