VFDs and Single Phase AC Motors

My first job out of school was with a motor manufacturer providing technical support. Being in the Midwest, we had a lot of farm and agricultural customers.

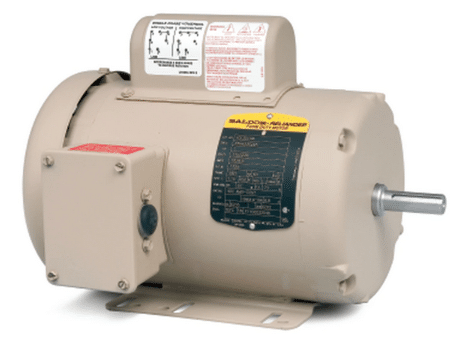

Their applications ranged from running fans, pumps, elevators, agitators, augers, conveyors, etc. The farm installations often didn’t have access to three-phase power and had to make do with single-phase 230V. We sold a lot of single-phase Farm Duty/Ag motors into these installations.

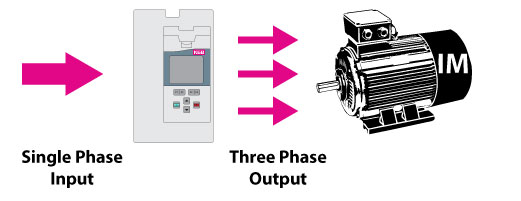

People often wanted to run the motors at reduced speeds so they asked, “Is it possible to add a VFD to my single phase motor?” In general, single-phase motors cannot be run with VFDs. However, it is possible to input a single-phase to a VFD and output variable voltage to a 3-phase induction motor. This article describes how that works and offers some considerations.

The Problem with Line Feeding Single Phase Motors

One challenge to operating large single-phase AC motors from the line is the starting current. A 10HP single phase motor will pull 38A nominal (at 230V).

But that motor (NEMA B design) will pull 6-8 times the nominal current when starting up – or 234 Amps! This high amp draw can cause issues at the distribution panel. Even the utilities might notice.

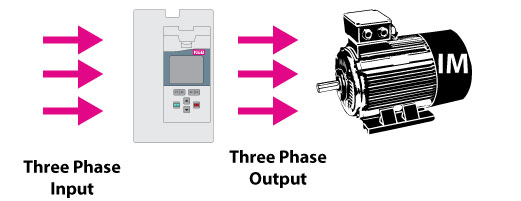

To be fair, the problems associated with high starting currents will also affect a line-fed three-phase motor. But in the case of a three-phase motor, a person can easily add a VFD. One benefit of VFD operation is that while ramping up the motor speed, it will limit the motor current so these large peaks are avoided.

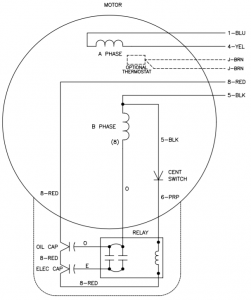

The Centrifugal Switch in Capacitor-Start Single Phase motors

There are a few different designs of single-phase motors. I’ll highlight the one I have seen most in industrial applications – ones with a capacitor start and centrifugal switch. The design uses a capacitor network that is in the motor circuit at low speeds. The capacitors help provide torque at zero speed and get the motor started in the correct direction.

Once the motor is spinning and has inertia, a centrifugal switch opens and the capacitor network is disconnected from the primary motor windings. The speed at which the switch opens happens before reaching the motor’s normal operating speed at 60Hz.

For this reason, it is not a good idea to use a motor designed for 50Hz on a 60Hz main. At least not without swapping out or adjusting the centrifugal switch. It could be possible, that the switch never opens when running at 50Hz. This could damage the capacitors or overheat the motor windings.

Related Article: Motor Thermal Protection

A similar concern would be using a VFD to control the speed of a single-phase motor. Lowering the speed would effectively keep the capacitors in the circuit for extended periods of time and could potentially damage the motor.

Single Phase Input to VFD

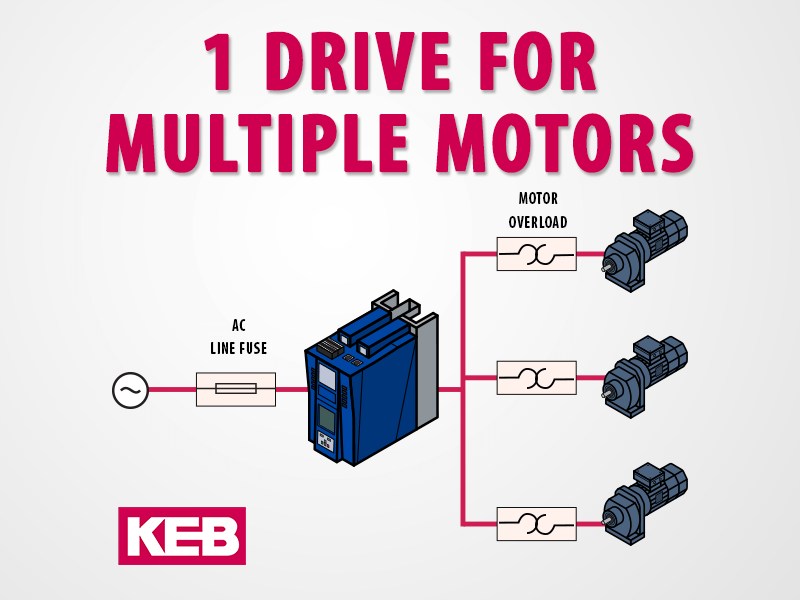

So if you can’t use a VFD with this design of a single-phase motor, what is the solution? The answer is to input a single phase to a VFD. The VFD can act as a phase converter and output a three-phase to a three-phase motor.

There are some considerations, particularly with sizing. Some VFDs are designed and rated to input both single and three-phase. Check with the VFD manufacturer but you’ll see something like this in the manual which denotes both phases.

With larger drives, the ratings tend to only indicate a 3 phase input. Single-phase input is possible but a single phase derating is likely needed.

Let’s look at a VFD application with three-phase input running a 10HP motor. Let’s assume there aren’t any losses and PowerIN = PowerOUT. The input current and the output would be the same.

Now, take that same application running a 10HP motor but with a single-phase input. PowerIN = PowerOUT. Except all the power at the input is now going through one conductor instead of three. Effectively, there is a √(3) factor applied to the single-phase input current compared to the three-phase current.

Again, some drive sizes already have input rectifiers over-dimensioned and can inherently handle the increased single phase input current – this should be reflected in the power stage ratings. For larger HP applications, the net result is the drive might need to be upsized to handle the larger input current.

As a rule of thumb, we suggest rounding up and assume the single-phase input current will be double that of the three-phase input current.

Finally, it is also a good idea to use a 5% line reactor when applying single-phase input power to a drive. During power-up, the drive will have an inrush of charging current to the unit. The 5% reactor will help reduce the peak charging current and protect the VFD’s input rectifier stage.

What about cost?

There is a price premium for single-phase motors, especially larger HP motors. Doing a quick calculation of that same 10HP motor from above and the single-phase variant is a +60% cost premium. My guess is that some of the added cost is due to the added parts of the capacitor network and switch. The other part of the cost is because larger single-phase induction motors are more of a specialty compared to the three-phase types.

Add in the additional cost of a VFD/reactor but also subtract out the premium for the single-phase motor. I think you’ll find the overall cost of adding a VFD is much less than you think.

Should I buy a Rotary Converter?

A phase converter is certainly an option. It will convert single-phase power to three-phase power. But that is all it does. It does not offer the many advantages that a VFD will offer. This includes the ability to control the motor speed, better performance at low speeds, protection functions, and motor temperature monitoring.

There is also a similar argument to be made on the cost of a phase converter. The phase converter will likely not save much, if any money, compared to a drive.

Advantages of Using VFDs in Single-Phase Applications

A user will benefit from going from a line-fed motor to a VFD-controlled motor. They will be able to optimize the motor speed for the process. Maybe this means slowing the conveyor down during loading instead of completely shutting off the motor. Lightly loaded motors can also be oversped to speed up processes – like a conveyor or auger for example.

A user will also benefit from the energy savings due to the VFD. Especially quadratic load applications like fans and pumps. The higher duty of the application, the more savings there will be. Add some basic feedback to the application like a temp or humidity sensor and the VFD can be wired to regulate a process. KEB’s F5 even has a built-in PID controller so the entire process can be regulated inside the drive – removing the need for an external PLC or control

One advantage of VFDs that is often overlooked is all the protective functions they have that detect abnormal situations.

- Over/Undervoltage – Automatically shutdowns when there is a brownout or power surge.

- Motor Overheat – This option requires a thermistor or motor temp sensor. It protects the motor investment and is a good idea for expensive motors, difficult-to-service motors, and high ambient temperature applications.

- Overcurrent protection – This could detect an abnormal fault like a shorted motor winding and shutdown.

There are many more protective features for sure, but you get the idea.

KEB Single Phase VFDs

KEB’s F5 drive can be used with Single Phase installations. Download a manual on the F5 VFD product page or contact a KEB America engineer to discuss your application and decide which VFD is right for your application.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.