Functional safety (FS) is a crucial element in machines and automation. FS aims to minimize safety risks associated with machinery to protect operators, passersby, and the equipment itself. FS solutions vary in scale and complexity, from simple temperature sensors to emergency brakes and PLCs. These protective tools help save lives, eliminate risk, and ensure optimal performance across machine operations.

What Are Functional Safety Requirements?

Many industries have functional safety standards. These requirements ensure that machines and products used within that industry are functionally safe and compliant. Each of these FS standards has a unique code. For example, ISO 26262 is a safety standard for electronic and electrical (E/E) safety-related systems. ISO 26262 addresses potential hazards that can emerge in the E/E systems of vehicles to mitigate their frequency and effects.

Why Is Functional Safety Important?

Functional safety is important because it protects people, equipment, and work environments from harm. Industrial workplaces use powerful machines and automated systems, which can expose operators to severe safety risks. Machine emissions and dangerous movements put lives and livelihoods at stake, which is why it’s imperative to detect and control these threats.

How Are Functional Safety Requirements Maintained?

Functional safety requirements are constantly evolving as new technologies and innovations emerge. Before a system or machine is introduced into an industry, it must first be tested and certified functionally safe. This is achieved with the help of functional safety engineers. These professionals work closely with engineering, procurement teams, and suppliers to make all systems functionally safe and compliant.

Functional safety engineers perform extensive safety tests and hazard analyses of machines and systems based on relevant FS standards. This may also encompass the creation of safety concepts and FS documentation. Functional safety engineers ensure that all FS standards are met across the system’s entire life cycle.

Industrial Applications for Functional Safety

FS is employed across a host of industries, from automotive and railway transportation to metalworking machinery. Each industry has its own list of safety standards fulfilled with powerful FS solutions. For instance, the medical field uses complex equipment like surgical robots, beds, booms, and imaging machines to drive care outcomes for patients. These tools can be augmented with spring-set or permanent magnet brakes and clutches to enable extremely accurate control, braking, and positioning.

Packaging machines can deploy FS drives to add Safe-Torque-Off (STO), Safe-Brake-Control (SBC), and additional safety functionality. FS drives also help to reduce wiring, create faster power cycles, and improve response times.

Material handling applications benefit greatly from FS products, particularly electromagnetic brakes. Rollers and automated storage and retrieval systems (ASRS) equipped with custom brakes offer exceptional control and safety. FS brakes for material handling unlock new efficiency across the supply chain, as goods are safely moved, stored, and shipped to their proper destinations.

Industrial Solutions for Functional Safety

Functional safety products protect people, machines, and work environments from various hazards resulting from faulty equipment and technology. Here’s a list of common FS products used by industrial businesses to mitigate safety and compliance risks:

FSoE Safety PLCs

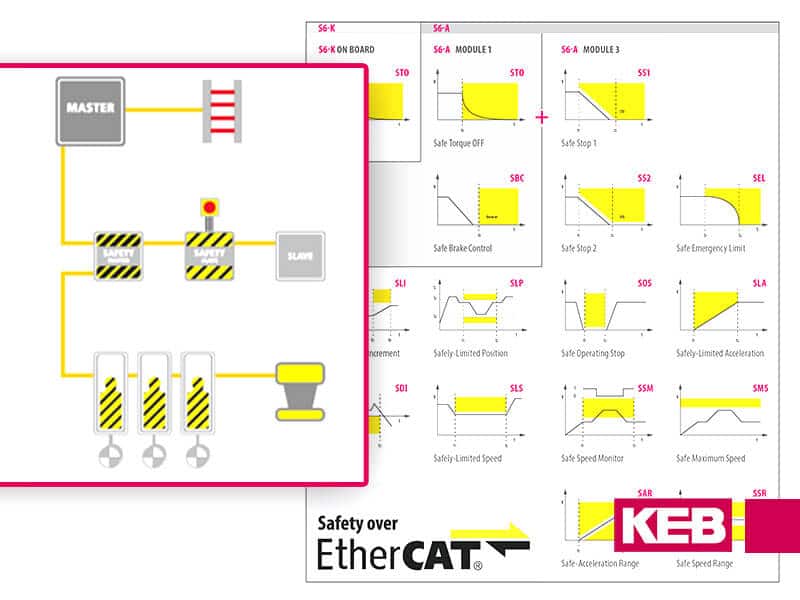

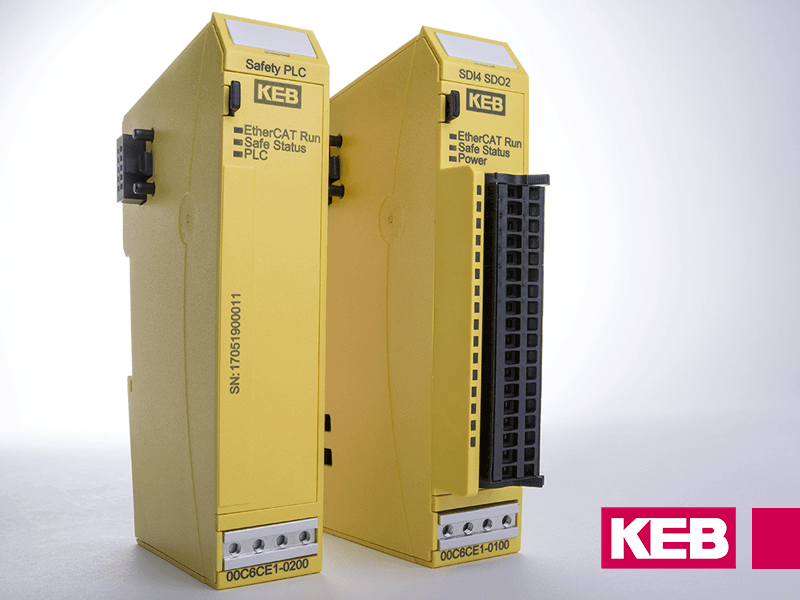

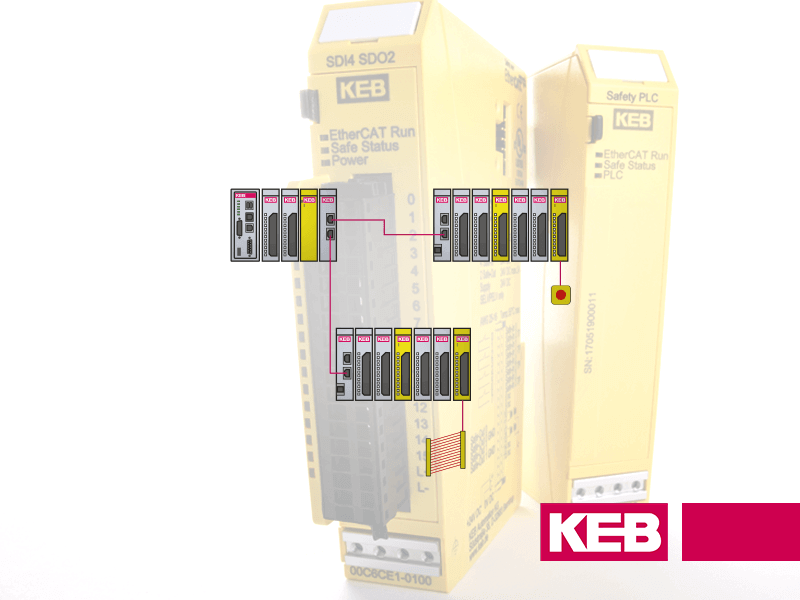

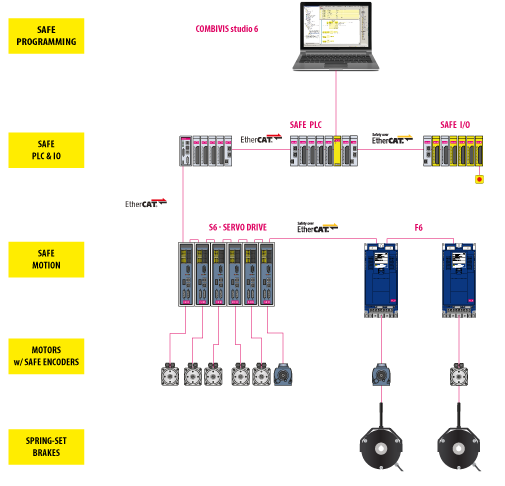

Functional Safety over EtherCAT (FSoE) PLCs can pair together with safe I/O and COMBIVIS PLC software. This combined solution gives users a single robust platform to program their safety and machine controls. All connections to the FSoE PLC can be made with a network cable, allowing users to replace older outdated wiring with efficient network cabling.

FSoE Servo Drives

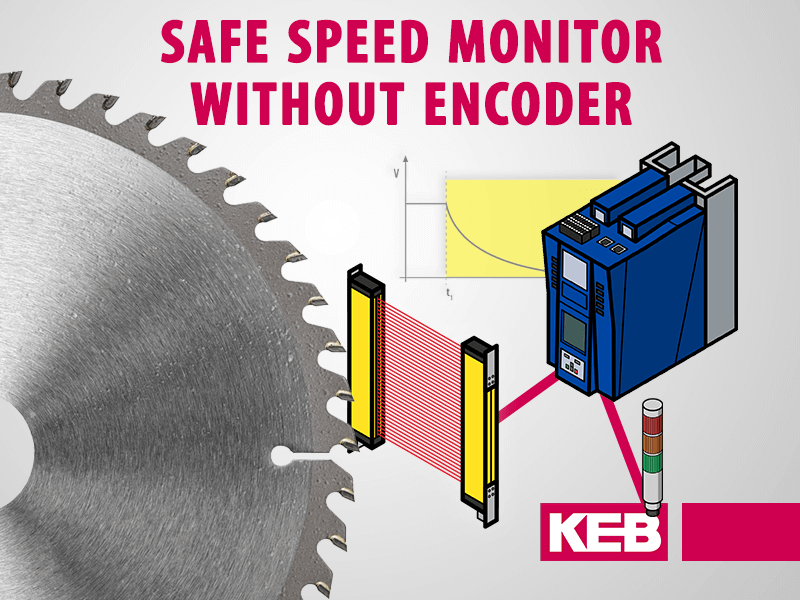

FSoE S6 Servo Drives work alongside the safety PLC to enable high-performance servo applications. S6 servo drives support many leading communication protocols (including EtherCAT and EtherNet/IP) while enabling real-time communication, integrated brake control, and advanced SIL3 safety.

Spring-Applied DC Brakes

DC brakes are durable electromagnetic brakes that can be mounted on a motor or drive shaft. These spring-applied brakes are built to excel in tough applications and can be used for holding, dynamic, and e-stop braking. DC brakes do not feature solenoids or parts that will wear down and demand frequent replacement, making them an ideal choice for applications requiring constant uptime.

KEB: Your Partner for Functional Safety Solutions

KEB offers a wide selection of FS products to maximize safety for your machines and operators, including emergency or spring-set brakes, Safety PLCs, and SIL3 VFDs. All our FS products are certified by 3rd Party TUV agencies to ensure they meet regulatory requirements and deliver unmatched reliability and safety for your business. We act as a single-source provider of trusted safety solutions for customers around the world.

To learn more about functional safety requirements and how your business can leverage FS products to meet and exceed these standards, contact a KEB solutions engineer today. Our team will work with you to design a flexible FS solution for your unique business and application needs.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.