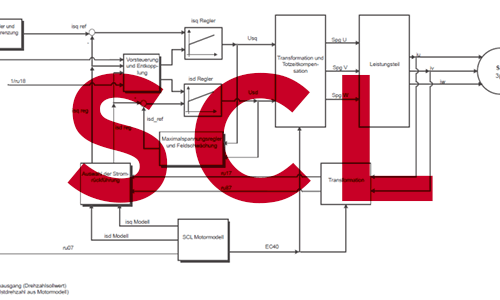

What is Sensorless Closed Loop? Precise Motor Control without an Encoder

Usually, when choosing how to drive an AC motor, the user must choose between open-loop V/Hz control or closed-loop control with an encoder. With these options, the decision-maker must choose between the functional simplicity of V/Hz operation or the dynamic response of operation with an encoder.

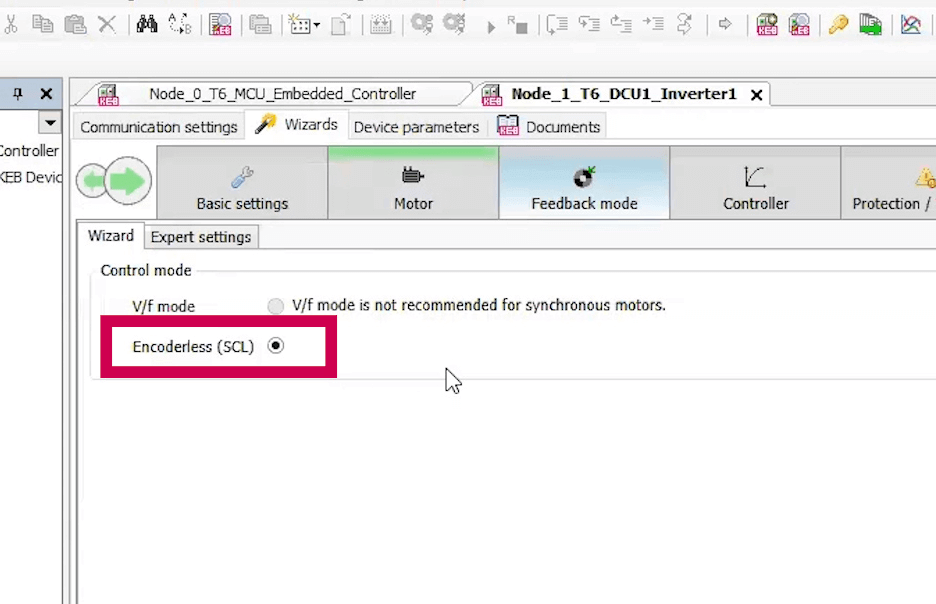

However, KEB offers a third option that combines the best features of both. That third option is called “Sensorless Closed Loop™” (SCL/ASCL). Sensorless control offers dynamic, closed-loop performance without needing additional hardware (encoder/resolver/cables) on the motor.

Motor Model

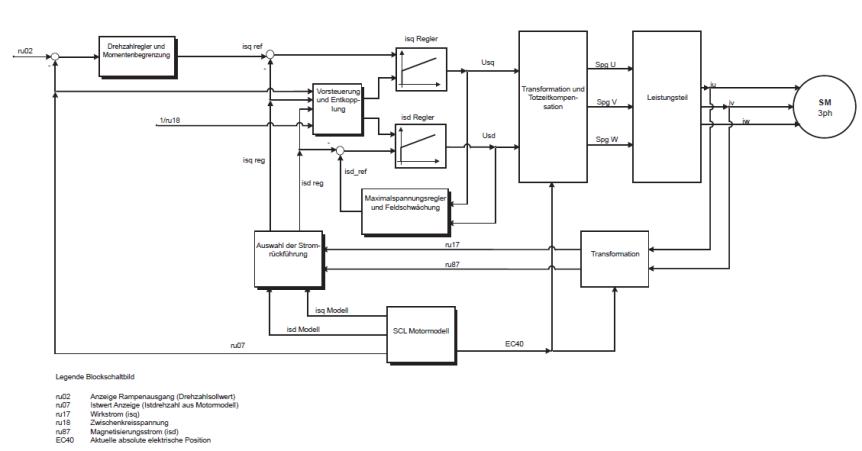

Although no sensor provides feedback, sensorless control still operates in true closed-loop operation. Instead of an external sensor, sensorless uses a sophisticated motor model to close the loop. In this way, sensorless acts like a virtual encoder.

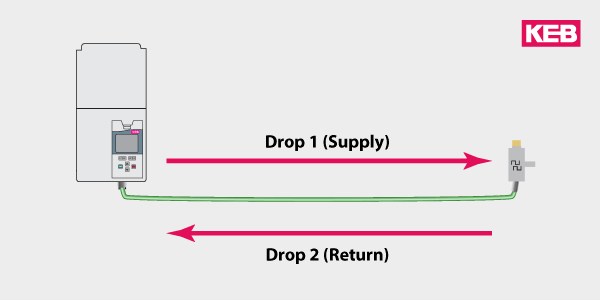

The motor model compares calculated current and voltage levels and compares them with actual values to deduce the position and speed of the motor. This offers the benefit that the required values can be read internally from the same cable that powers the motor, requiring no additional hardware and removing potential points of failure.

Dynamic Performance

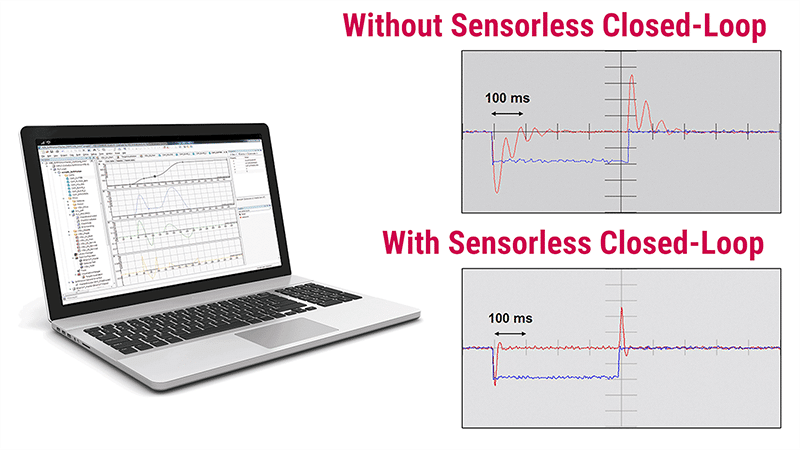

As stated, sensorless control requires no additional hardware than what would be required for open-loop operation. One might assume that sensorless can’t compete with encoder-based operation, but this is far from reality.

Sensorless performs with a similar dynamic response to that offered by an encoder. Sensorless control’s ability to track the speed and position of the shaft makes it ideal for scenarios with variable load.

Benefits

Sensorless offers several advantages compared with open-loop and encoder-based operations. Since sensorless control combines the best aspects of each, comparing them one by one is useful.

Vs. Open-Loop

- Sensorless control can respond dynamically, while open-loop operation adapts poorly to variations in load.

- Sensorless offers more accurate control of speed because it more directly measures the shaft performance.

- Sensorless offers torque control, while open-loop V/Hz operates with constant torque

Vs. Encoder-Based

- Sensorless eliminates the cost of the encoder and the corresponding feedback cable.

- Sensorless removes the encoder and cable as a potential point of failure.

- One limitation of sensorless is that it is not intended for applications requiring full holding torque at zero speed since the motor model relies on voltage feedback from the movement of the rotor.

- Sensorless is more reliable than an encoder because it is not susceptible to vibration and EMI.

Applications for Sensorless Control

Sensorless can offer improved performance for several applications. However, the most benefits are seen in applications where space, vibration, and electrical noise are concerns.

- Sensorless helps save space by removing an additional bulky cable from the system.

- Sensorless exceeds expectations in high-vibration environments because it removes the encoder, is vulnerable to vibration, and can become a potential point of failure.

- Sensorless is a good fit for areas where electrical noise is a concern because it eliminates a susceptible, low-voltage cable.

Conclusion

Sensorless motor control continues to be a valuable feature of KEB inverters. Implementing this technology increases performance, and reliability, and can introduce significant cost savings.

If you are interested in seeing how “Sensorless Closed Loop” can benefit your application, please get in touch with a KEB engineer using the form below.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.