Combivis – Powerful VFD Software for Commissioning and Programming

Combivis 6 is KEB’s drive programming VFD software. Use the software to program and configure the KEB VFD, find documentation, and troubleshoot machine issues with its 16-channel scope function.

While some companies charge for their VFD programming software, KEB does not. Users can download Combivis Studio 6 here.

This post is a basic overview of some of the powerful Combivis VFD software features that help the development and support of KEB drives.

KEB Device Scan

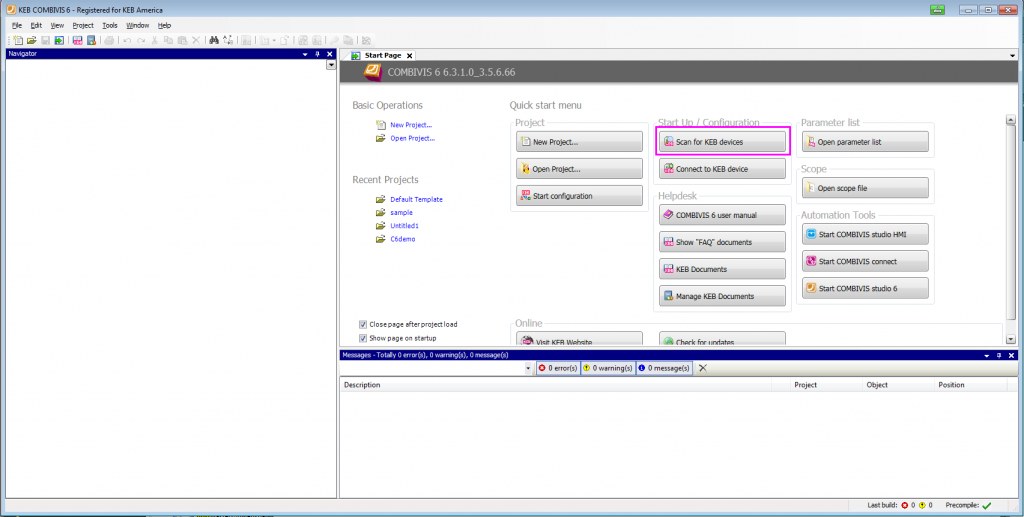

When troubleshooting a machine, the last thing you want is another problem to arise. For example, your PC will not communicate with your automation equipment. Instead of manually tweaking baud rates and COM ports to scan, Combivis 6 will scan a full range in search of a KEB device automatically. The KEB Device Scan function can be easily activated by clicking the “Scan for KEB devices” button on the start page of the software.

Figure 1: Combivis 6 home menu

You can then select Serial, TCP/IP ports, or both to scan over a range of baud rates/addresses for KEB devices.

Up/Download Functionality

To replace a VFD in the field, you want to make sure the new unit has the correct program in it. The best way to ensure this is to take an upload from the existing VFD and download it into the new one. This can be done using KEB’s VFD-to-USB converter (part number 0058060-0040) which can handle multiple forms of communication (Serial, HSP5, etc..), and the Combivis 6 software.

Throughout the industry, there is some confusion on the terms upload and download when they are referring to VFD programs. Luckily, in Combivis 6, if you hover your mouse over an upload or download button, it spells out the action it will perform:

Once your parameter list is uploaded from your VFD, you can save it to download into another or several other VFDs.

Documentation

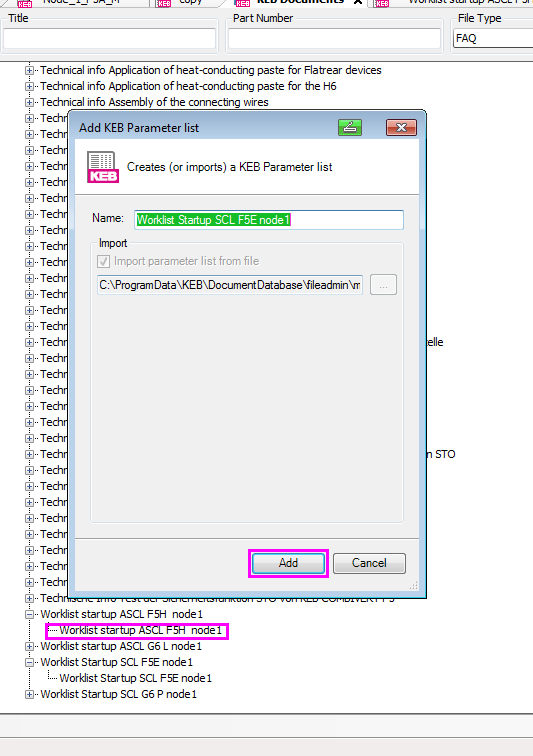

Once you register your Combivis VFD software for free, you will have hundreds of user manuals and FAQ documents at your fingertips. A user can manage the documents and save them locally. Also, it is possible to auto-update the manuals to have the latest revision.

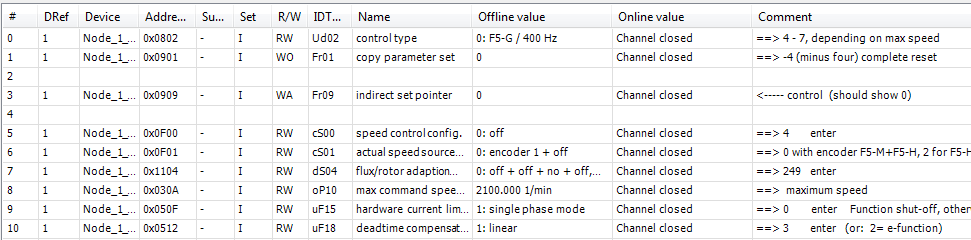

The FAQ documents contain parameter lists that have been put together by KEB Engineers to assist users with startups of advanced drive functions. Take, for example, KEB’s powerful sensorless closed-loop (SCL) functionality. SCL allows you to run a motor with closed-loop performance speed and torque control without the use of an encoder. This functionality requires you to input motor and control parameters which can be a daunting task if you are unfamiliar with VFD programming. The FAQ worklist available in Combivis 6 allows you to import a parameter list complete with comments to enter into your KEB VFD:

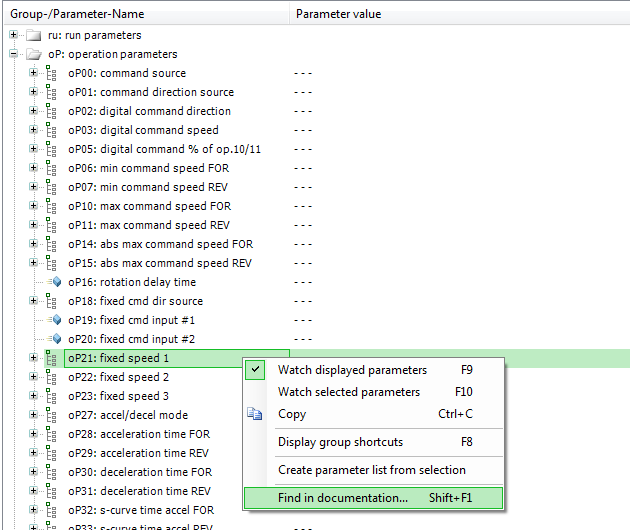

Along with FAQ documentation, you can right-click on any drive parameter and look it up in the application manual.

Wizards and Scope

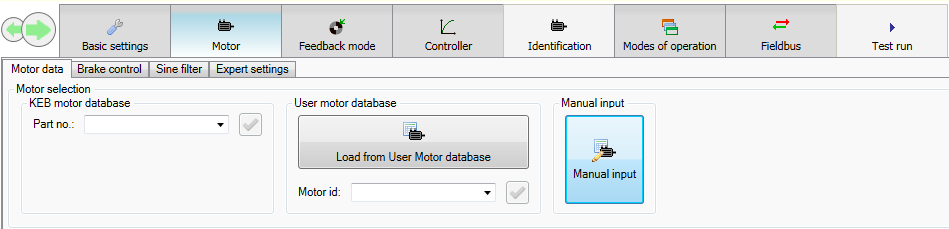

Combivis 6 has start-up wizards that allow you to have a motor spinning in a matter of minutes with no VFD programming knowledge required. When you connect to a KEB VFD, a wizard tab will populate which allows you to step through basic speed control settings, motor data, encoder setup, and fieldbus communication setup.

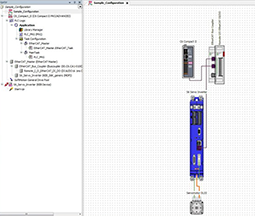

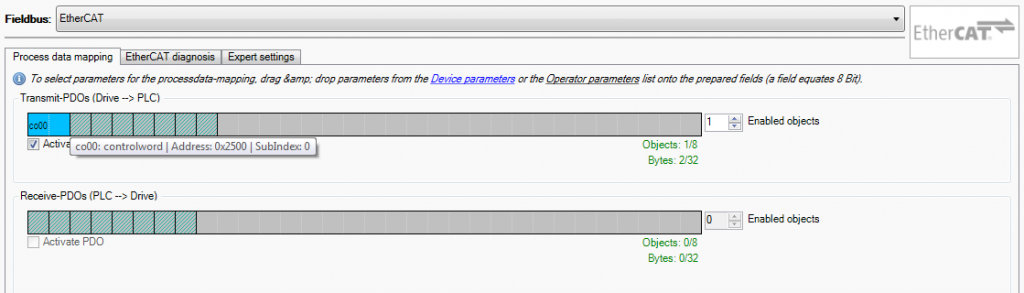

Setting up your EtherCAT process data is simply a drag-and-drop task in Combivis 6 VFD software. The process data wizard handles all of the addressing and once the user has picked all of the transmit and receive PDOs, they can export an XML file from Combivis 6 to load into the PLC.

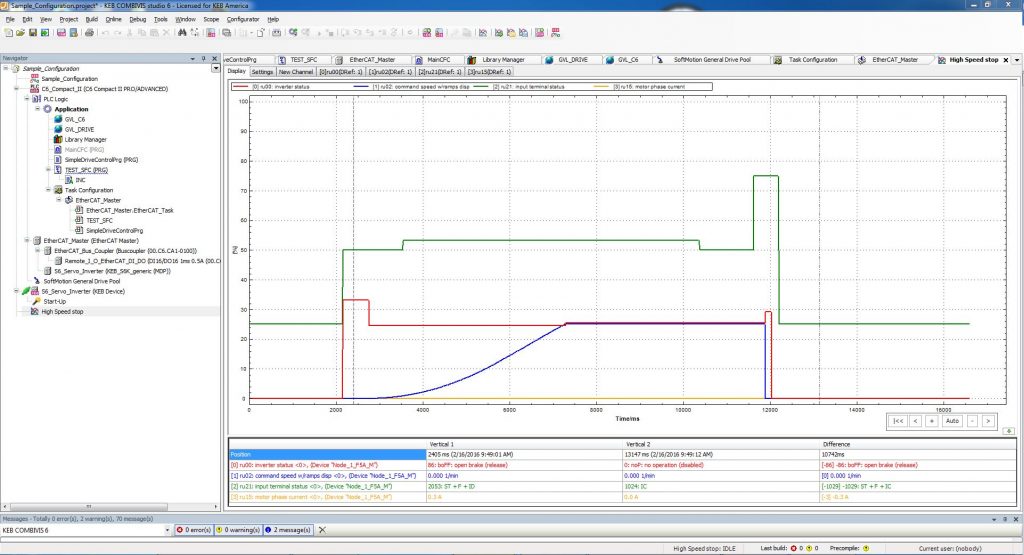

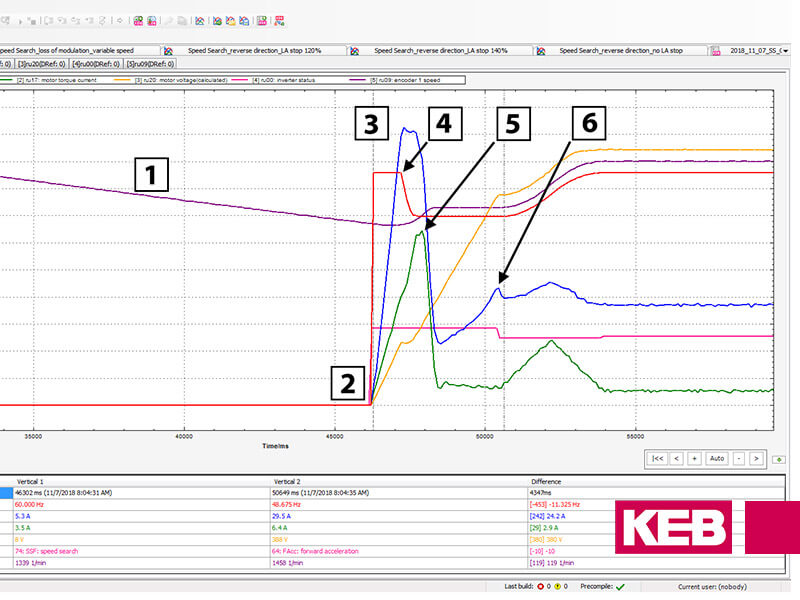

16-Channel Scope

One of the many (and possibly the most useful) tools within Combivis 6 is the scope. The scope can monitor and record up to 16-channels in real-time. With the Combivis 6 scope, you are able to monitor the drive and system behavior during machine setup or during operation.

Some common parameters to monitor are encoder speed, motor phase current, DC bus voltage, actual position, etc…

Figure 8: Combivis Scope traces

Combivis 6 VFD Software – A Valuable Tool in Optimizing Motor Performance

Combivis 6 VFD software is your one-stop resource for programming, startup, and maintaining your drive. You can download the software for free on the KEB Combivis VFD software page. Contact a KEB America engineer to learn more.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.