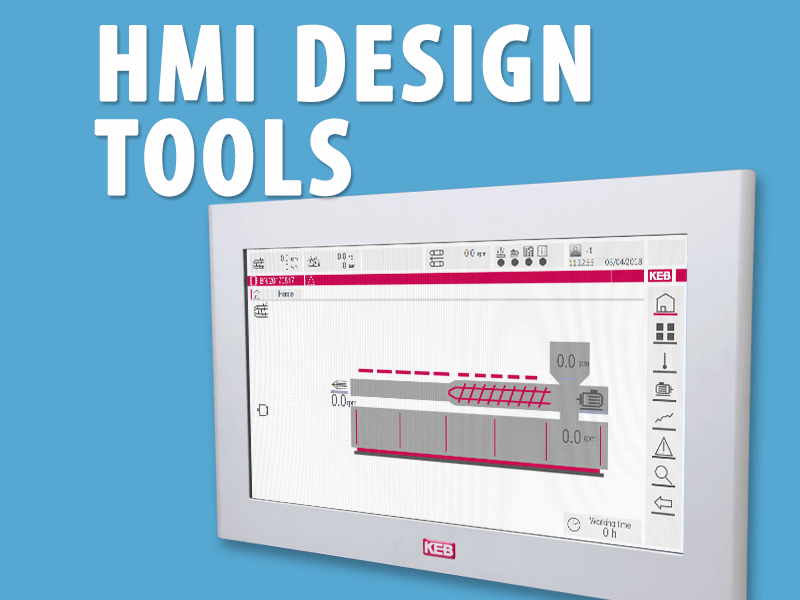

COMBIVIS Studio HMI is used to program KEB’s HMI products. Studio HMI features built-in features like dataloggers, recipes, and alarm handling. Projects can be easily scaled up and down depending on the HMI screen size. The HMI and Software support over 40 drivers including EtherNet/IP and can be used with 3rd party PLC platforms.

COMBIVIS HMI

Product Details

Create HMI projects. Sync projects in Studio 6 for seamless integration.

40+ drivers which allow KEB HMIs to be used with Allen-Bradley, Siemens, and Schneider PLCs.

Advanced Runtime supports Datalogging (between 1024-4096 tags). Much more economical than other historian platforms.

Enable SMS texts and e-mail alerts.

Advanced Recipe handling and Alarm Management

COMBIVIS HMI product Introduction:

COMBIVIS HMI product environment overview:

Tutorials

1. Getting Started - How to Create a Project

The document below explains how to create a COMBIVIS Studio HMI project using the “New Project Wizard.” Tap the link below to download the PDF that will take you through the steps to get started with our KEB HMI software.

2. Working with Screens

This document explains how to perform basic screen navigation in a Studio HMI project. The following sections will describe the tasks of (1) changing screens, (2) using popup screens, (3) using embedded screens, and (4) setting a startup screen.

3. Configuring Alarms

This document explains how to create alarms in an HMI project. Alarms are useful for displaying critical machine and safety information to the operator. In addition, the alarm dispatcher may be used to send SMS and email alerts to those impacted by the alarm condition.

4. Recipes

This document explains how to define and manage recipes in an HMI project. Recipes allow operators to easily switch between sets of parameter values during runtime. This is especially useful for changing machine parameters within a production process.

5. Parameterized Screens Using Alias Variables

This document overviews how to parameterize a screen. Parameterized screens are useful in cases where there are similar data sets that should be displayed and/or edited in a visualization. Rather than creating a screen for each data set, a single screen may be parameterized to display any of the similar data sets. This saves development time, and project memory size, and allows for a cleaner project.

6. Dynamic Text Using the String Table

This document explains how to use the String Table feature of Studio HMI to display dynamic text, and active screen information, and define multiple languages for the user interface.

7. Users and User Groups

This document explains how to create users and user groups and control their access to an HMI project.

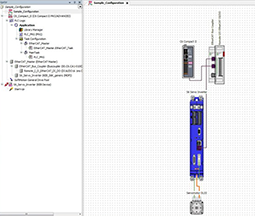

8. Communication Setup Between KEB PLC and HMI

See how to exchange variables between COMBIVIS Studio 6 and Studio HMI through the Symbol Configuration. This allows read/write operations between a PLC and HMI visualization, giving the HMI users the ability to view tag values as well as edit them if desired.

9. How to Upload, Download, and Delete HMI Projects

This document explains how to upload, download, and delete COMBIVI Studio HMI projects on KEB devices.

Allen Bradley Micro800 Communication Setup and Tag Import

This is how to set up an Allen Bradley Micro800 Ethernet/IP communication driver and import tags from a Rockwell Automation Connected Component Workbench (CCW) project.

Allen Bradley Ethernet/IP Communication Setup and Tag Import

This document explains how to set up an Allen Bradley Ethernet/IP communication driver

and import tags from a Rockwell Automation Logix 5000 project.

Allen Bradley Ethernet/IP Setup PDF

AB Ethernet/IP Communication Solution Zip File

Siemens TIA Communication Setup and Tag Import

This is how to configure communication between a Siemens S7-1200

PLC and a KEB HMI product using both Profinet and TCP/IP.

Lets Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

Let's Talk

KEB has helped our customers solve many automation challenges. Let’s discuss your challenges and goals and see how we can help.