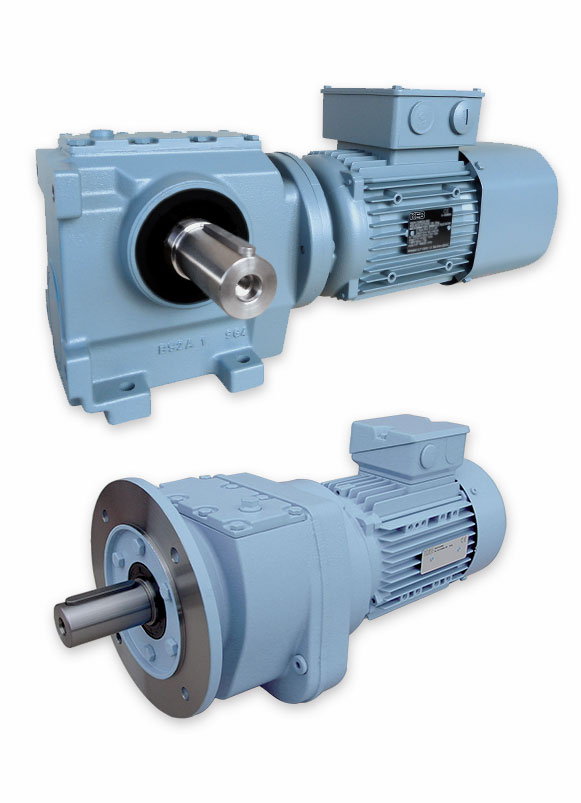

KEB's helical bevel geared motors offer compact and efficient power transmissions. They are ideal for applications requiring a right-angle output. Regardless of your gearing, our gearmotors are highly flexible and customizable and have many product configurations.

Helical Bevel Gearmotors

Product Details

Integral design provides a compact design and lower weight compared to flanged designs.

KEB’s high-quality two and 3-stage helical bevel gearmotors offer 94-96% efficiency.

Gearmotors can be supplied with solid output shafts or hollow bores.

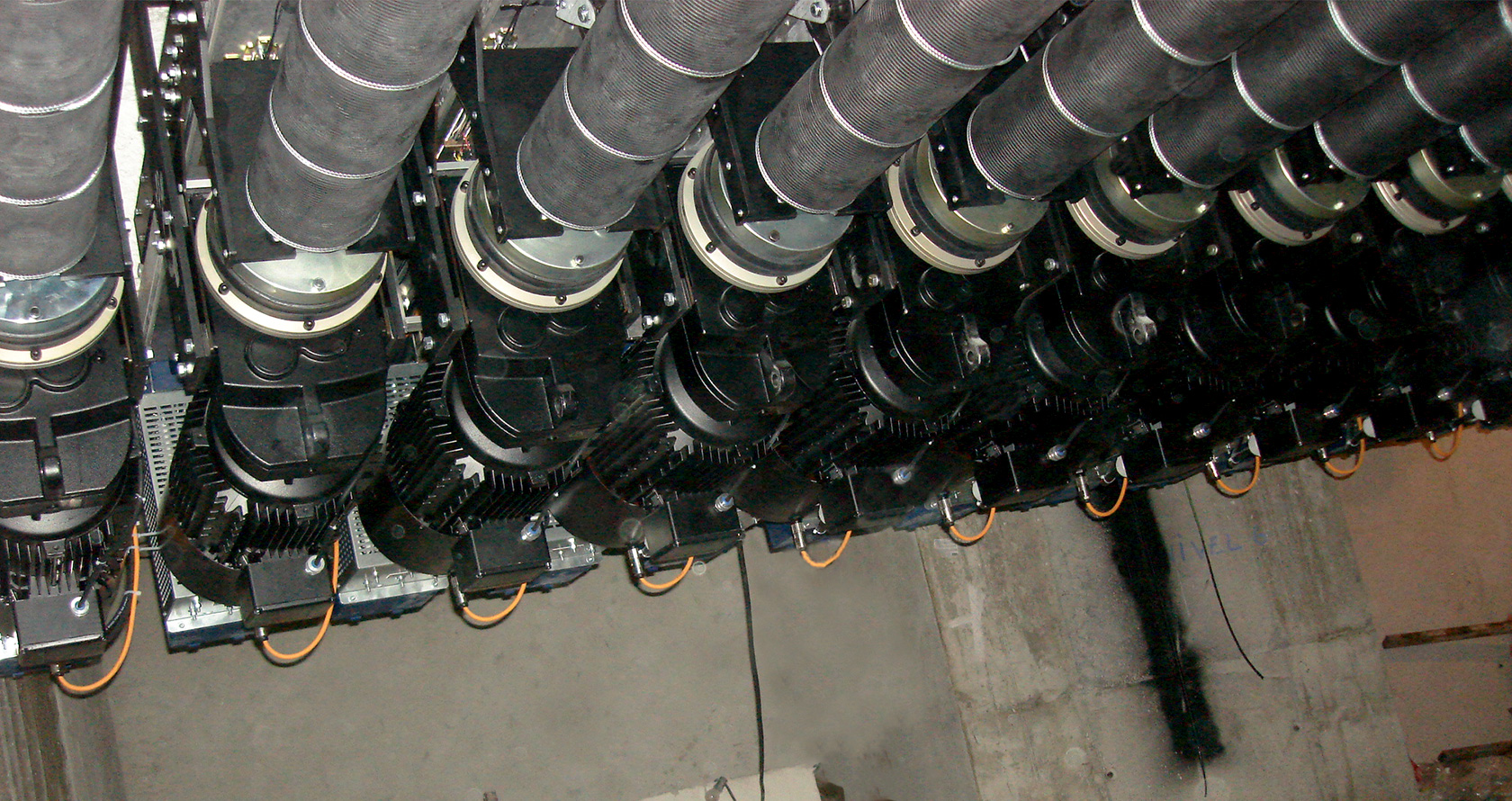

KEB gearmotors excel in demanding hoisting and cycling applications.

Designed to work with a failsafe spring-applied brake. Configure with a hand release, micro switch, or noise dampening.

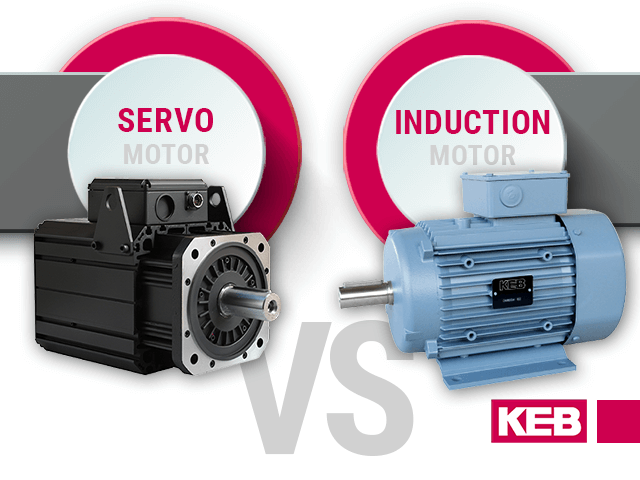

Helical bevel gearing can be added to a PM servo motor or an induction motor (IE2 & IE3).

Tech Specs

Mechanical

• Output Torque: Up to 15,000Nm

• Brake Option: KEB Spring-set Brake

• Backlash: 10-20 arm/min. as standard. Low backlash option exists

Environment

• Protection Type: IP55 standard. Up to IP65 available.

• Maximum Ambient Temperature: 40° C with possible derate

• Elevation: 1000m rated with possible derate

Options

Spring-set Brakes: Add a spring applied (spring-set) brake to your gearmotor. KEB COMBISTOP Spring Set brakes provide failsafe braking functionality with boosted coils for higher torque and a robust design for tough industrial applications.

KEB brakes provide power-off brake engagement. The brakes used are KEB’s Type 38 brake which includes common options like a manual hand release and micro switch. A quiet brake is available for theatre and stage applications.

Feedback devices

KEB motors can be configured with feedback devices. Common formats include: TTL, HTL, resolver, BiSS, and Hiperface.

Customized outputs

KEB can provide gearmotors with custom flanges or shafts to facilitate mounting to the machine. It is also possible to provide an output flange or shaft on both output sides.

Food Grade Lubricants

For use in food production, KEB gearmotors can be provided with food grade lubricants and greases.

Extra Environmental Protection

For use in washdown or corrosive environments, the gearmotors can be supplied with extra paint protection and seals.

Helical Gear Applications

Helical gears are renowned for transmitting motion and power between non-parallel shafts. By applying helical gear technology, industries benefit from wear-free operation and a long service life, ensuring reliability and performance.

With the application of helical gear technology, industries benefit from wear-free operation and a long service life, ensuring reliability and performance. The unique design of helical bevel gearmotors provides solutions capable of handling up to 200 kW, delivering high torque efficiently.

These gears reduce operating costs due to their high efficiency. Helical bevel gear units are engineered for excellence, offering high-endurance gearing solutions that withstand the most demanding operational conditions.

Incorporating helical bevel gearboxes into systems, from automation to heavy machinery, improves performance and reduces maintenance needs. The superior design of these gearmotors aligns with the need for sustainable and cost-effective industrial solutions.

By optimizing operational efficiency and durability, helical bevel gearmotors contribute to a greener and more economical future.

Best Applications for Helical Bevel Type Gearmotors

Typical applications for our helical bevel gearmotors include industrial door lifts, theatre hoists, and cable drum driving. Our gearmotors can be mounted by either foot or flange mount, and we can machine custom flanges to fit your application needs.

The bevel gearing provides a right-angle output. We offer hollow shaft outputs as well as a variety of custom-machined solid output shafts.

The popularity of KEB's helical bevel gearmotors stems from their high efficiency, versatility, and cost-effectiveness. They are ideal for applications needing continuous high-output torque, which sets the stage for understanding their superior efficiency compared to worm gearmotors.

Considerations

Sizes Available

KEB’s helical bevel gearmotors range from .25hp to 50hp, and we offer many complementing options/add-ons for whatever your application may require.

Upfront Cost vs Lifetime Cost

Although the initial cost may be higher for the helical bevel gearmotors, the long-term operation costs will be higher if you select a worm gearmotor. You will pay much higher energy costs since the worm gearmotor is less efficient than the KEB helical bevel gearmotor.

Efficiency of Helical Bevel Gearmotors vs. Worm Gearing

People often think that worm gearmotors are the better option because they can achieve the desired output speed and torque for an application at a lower price. However, a drawback to worm gearmotors is the less efficient operation when compared to helical bevel gearmotors. Watch 5 Main Gear Types & Their Characteristics

Worm gear efficiency is often around 80%, but KEB's helical bevel gearmotors are 90+ % efficient. The higher efficiency comes with other benefits, such as less heating and less audible noise when compared to worm gearing. Additionally, you can use a smaller motor for a given output torque.

IE3 Efficiency Standards

Rising energy costs have been a big topic recently, and they will continue. Governments have long understood that electric motors are a large consumer of electrical energy globally and have been working to adopt legislation to increase motor efficiency.

KEB understands the changing landscape and has made electromagnetic changes to the stator windings to meet the higher IE efficiency requirements in Europe and North America.

Read More: Addressing the Energy Crisis Through Motor Efficiency

Brake Solutions for Gearmotors

We can add our spring-applied brake solution to the non-drive end of the motor for applications where dynamic braking is needed or for applications where a secondary holding brake is necessary. We can even mount a load brake onto the output of a helical bevel gear motor for hoist and theatre applications.

We offer both incremental and absolute encoders for applications requiring strict positioning, and we offer an IP65-rated gearmotor solution for washdown applications.

Discover the full potential of KEB's helical bevel gearmotors for your applications. For detailed information and personalized assistance, please contact our sales engineering team.