KEB line chokes provide input impedance which helps reduce harmonic distortion and increase VFD component lifetimes. KEB load reactors help reduce dV/dT switching peaks and increase motor life.

Line Reactors

Product Details

Full graduated offering for both 230V and 460V applications.

Improve system performance. Line reactors lower peak charging currents, reduce harmonic distortion, and minimize ripple current on the DC bus.

Load reactors minimize the negative effects of a VFD’s PWM voltage spikes. Ultimately, increasing the motor operating lifetime.

Various impedances offered including 3% and 5%.

Robust overloads for demanding VFD applications.

Tech Specs

Electrical

• Voltage Class: 230V and 480V

• Rated Frequency: 50 and 60Hz versions available

• Overload Rating: 150-200% FLA for 60 seconds

• Impedance: 3% and 5% available

Certifications

• cULus or UL recognized

• CE

Environment

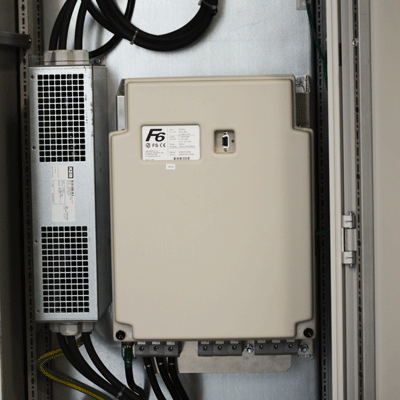

• Protection Type: IP20 standard (IP54 enclosed optional)

• Rated Ambient Temperature: Up to 40° C with possible derate

• Elevation: 2,000 meters with possible derate above

Options

Line Choke: A line reactor is placed at the input side of a VFD. The added impedance improves the drives harmonic current distortion level.

Motor Choke: A motor reactor is placed at the output of a VFD. It reduces the dV/dt levels of the PWM switching and increases motor operating lifetime.

dV/dt Motor Chokes: Specially designed dV/dt motor chokes are available for installations where the motor is mounted a significant distance away from the VFD (> 40 feet).

KEB dV/dt chokes are capable of being used with up to 16kHz switching frequency and have low inductances for use with PM servo motors.

Lets Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

Let's Talk

KEB has helped our customers solve many automation challenges. Let’s discuss your challenges and goals and see how we can help.