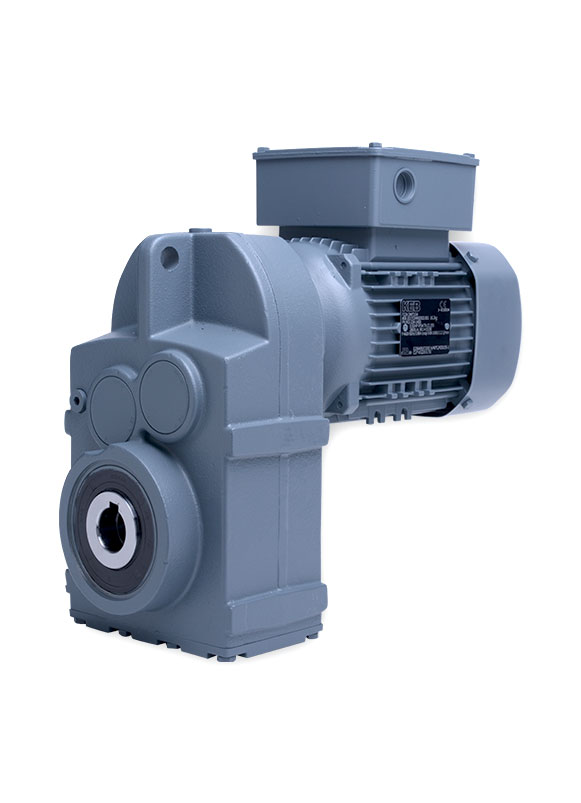

KEB’s parallel offset gearmotors are easily shaft mounted. Both metric and imperial sized outputs are available. Optional torque arms and shrink-disc fittings make assembly and zero backlash operation possible.

Helical Parallel Offset Gearmotors

Product Details

Integral design provides a compact design and lower weight compared to flanged designs

KEB’s German cut gears allow for an efficient compact gearmotor and are prepared to DIN 3990 specifications.

The optional shrink disc makes shaft mount assembly and disassembly easy.

Offset gearing can be added to a PM servo motor or an induction motor (IE2 & IE3).

Flange outputs, encoder, shaft couplers, food-grade lubricants, special paint are just a sampling of what is possible with this flexible product

Tech Specs

Electrical

• Voltage/Frequency combinations for different global installations

Mechanical

• Output Torque: Up to 15,000Nm

• Brake Option: KEB Spring-set Brake

• Backlash: 10-20 arm/min. as standard. Low backlash option exists

Environment

• Protection Type: IP55 standard. Up to IP65 available.

• Maximum Ambient Temperature: 40° C with possible derate

• Elevation: 1000m rated with possible derate

Options

Spring-set Brakes: Add a spring applied (spring-set) brake to your gearmotor. KEB COMBISTOP Spring Set brakes provide failsafe braking functionality with boosted coils for higher torque and a robust design for tough industrial applications.

KEB brakes provide power-off brake engagement. The brakes used are KEB’s Type 38 brake which includes common options like a manual hand release and micro switch. A quiet brake is available for theatre and stage applications.

Feedback devices: KEB motors can be configured with feedback devices. Common formats include: TTL, HTL, resolver, BiSS, and Hiperface.

Customized outputs: KEB can provide gearmotors with custom flanges or shafts to facilitate mounting to the machine. It is also possible to provide an output flange or shaft on both output sides.

Food Grade Lubricants: For use in food production, KEB gearmotors can be provided with food grade lubricants and greases.

Extra Environmental Protection: For use in washdown or corrosive environments, the gearmotors can be supplied with extra paint protection and seals.

Additional options include flange outputs, encoder, shaft couplers, food-grade lubricants, special paint