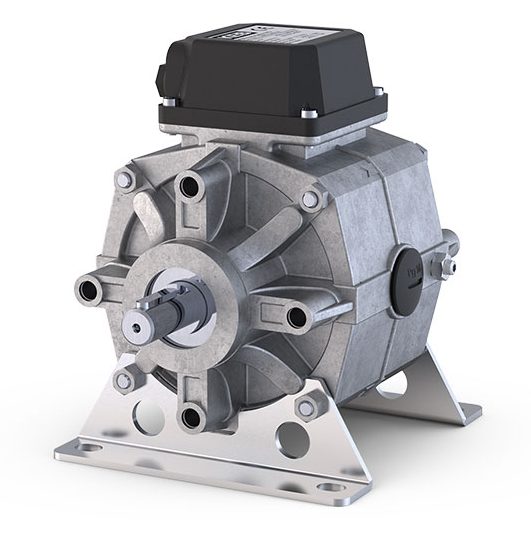

KEB DC brakes provide failsafe spring-set (power-off) brake engagement. The electromagnetic brakes are electrically released and typically mounted on a motor or drive shaft. KEB brakes are designed for tough applications and can be selected for dynamic, holding, and e-stop braking.

Spring Applied Brakes

Product Details

Power-off spring-set (failsafe) brake engagement.

Proven design with few wear parts – No linkages. No solenoids. No moving parts to wear and replace

KEB spring applied brakes use multiple springs – each rated for 10+ million cycles

Can be dimensioned for dynamic, holding (parking), and e-stop applications

Options like manual hand release, microswitch for brake engagement feedback, and IP66 protection

High quality machined parts. Unique airgap adjustment using hollow spacers. The airgap can be readjusted to compensate for lining wear. This effectively increases the brake’s operating lifetime by 3X

Scalable sizes from several in-lbs to 2000 ft-lb

Tech Specs

Electrical

• DC Coil Voltage: 12, 24, 48, 105, 205 VDC Standard (Custom upon request)

• Duty: 100% on

• Insulation Class: B (F available as option)

• Approvals: CSA, CE

Mechanical

• Type: Spring-set, electrically released

• Torque Range: 0.25 to 2000 ft-lbs

Certifications

CSA on Standard product

Environment

• Environmental Rating: IP20 standard (IP65 available)

Options

Manual Hand Release: A manual hand release allows the brake to be opened without electrical power.

A locking hand release option is also available.

Microswitch to verify the brake state or monitor lining wear.

Torque Adjustment Ring: A torque adjustment ring allows the torque to be manually adjusted and lowered by up to 50%.

Noise Reduced: The brake incorporates design features to reduce brake actuation noise.

The solution is rated <65dB @ 1 meter. Effectively, more quiet than the gearbox or switching contactors.

IP65 Rating: The brake is fully enclosed and incorporates gaskets and o-rings – Perfect for outdoor or washdown applications.

Double Brakes: Two independent redundant electrical and magnet circuits.

Meets DIN56921 and BGV C1 requirements.

Dust Protection Ring: Economical solution to protect against ingress of dust and debris. Rated IP44.

Prepared for Encoder: The brake can be prepared with tapped holes to allow the direct mounting of a motor encoder or tachometer.

Secondary Friction Surface: A secondary friction surface provides a suitable counter-rotation surface to prevent wear on the mounting device. It can also incorporate a custom bolt circle for the application.

Connectors: Special connectors can be added per the customers specification.

Conduit Box: A terminal box or conduit fitting can be added for terminal wiring.