The KEB Z1 harmonic filter allows users to comply with IEEE 519 power quality standards by reducing VFD distortion. Discover its unique design, features, performance, and sizes below.

Harmonic Filter

Product Details

The KEB harmonic filters reduce harmonic distortion and its adverse effects. These filters can achieve sub-8% THiD levels.

Features include:

● High-performance electrical grade steel provides 99% efficiency.

● With its passive design, no extra circuitry or controls are required. It can be easily added to existing installations.

● CE and UL listed.

● Graduated sizes are available and can be economically matched to each application.

Both 50Hz and 60Hz filter designs are available depending on the installation power.

Unique Harmonic Filter Design

The KEB harmonic filters utilize a patented design incorporating the inductor windings on a common core. This common core design provides the following advantages over competitor harmonic filters:

● High damping of mainline voltage overshoot

● Minimal oscillations due to rapid load changes

● Increased lifetime of intermediate DC bus capacitors due to the trapezoidal output of the voltage waveform (less DC bus ripple)

● Negligible DC bus voltage drop at full load

● Parallel operation of several VFDs from a single harmonic filter

● Low capacitive reactive power at idle or low loads

UL Rated Harmonic Filter Sizes

KEB harmonic filters utilize three-phase capacitors in a delta configuration. The three-phase capacitor design increases the symmetry and helps to protect the VFD from voltage surges in the event of a phase failure.

All three phases are disconnected simultaneously in the event of a capacitor failure. A phase failure on a competitor’s harmonic filters using single-phase capacitors can result in a severe voltage imbalance and cause damage to the VFD input stage.

● KEB harmonic filters are available specifically for applications with 480VAC, 60hz mains, or 400VAC (380), 50Hz mains.

● KEB harmonic filters are UL rated and available in sizes ranging from 23A to 400Amp rated input current.

● All KEB harmonic filters incorporate a circuit protection device on the capacitor banks of the harmonic filter. The capacitor banks are mounted independently of the inductor core assembly to allow for increased mounting flexibility.

● Capacitor contactor option available to disconnect the capacitor bank when the machine is idle.

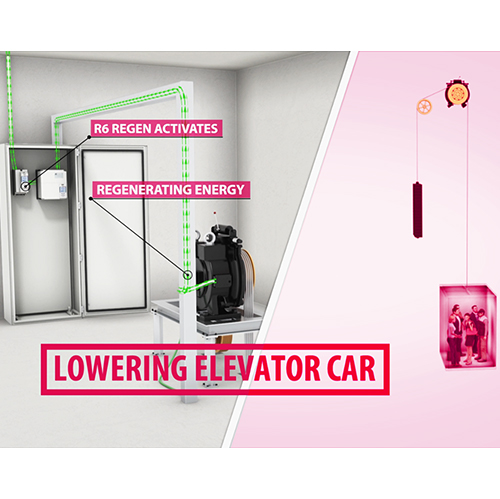

● KEB harmonic filters utilize lug-style power connections and can be equipped with a line sync module for use with the KEB R6 line regenerative unit.

KEB Harmonic Filters Performance

KEB has developed a line of harmonic filters designed to be used on the input of a 6-pulse full-wave rectifier. The standard KEB harmonic filter line is designed to reduce the total harmonic distortion (THD) of both current and voltage on the main input line to a maximum of 8%. This level is valid for an Isc /IL ≥ 20.

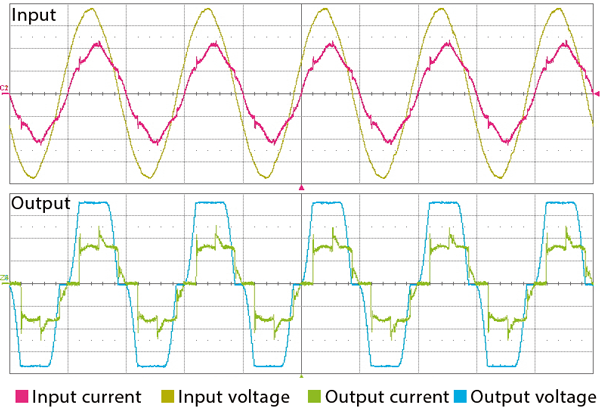

As an example of the effectiveness of the KEB harmonic filter, the following waveforms show the advantages of using a KEB harmonic filter.

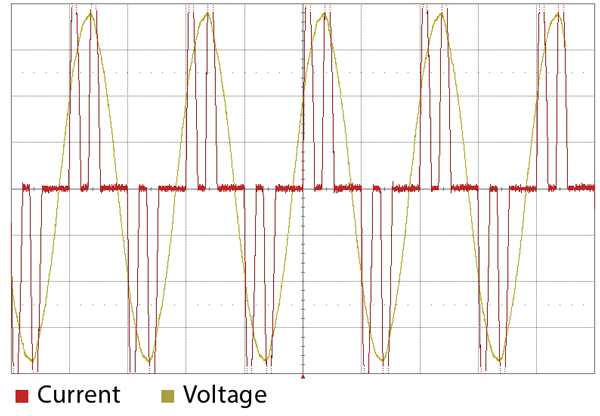

Voltage and current at the mainline – no line choke

Without a line choke, high current peaks (5 to 10 times the RMS value) occur, resulting in a high ripple current in the DC bus of the motor control. This also means higher ripple voltage on the DC bus which can lead to torque ripple or reduced torque output from the motor.

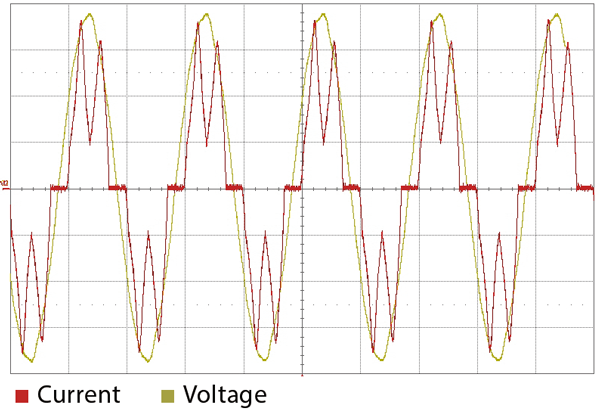

Voltage and current with line choke impedance = 3% 480V/60Hz (4% 400V/50Hz)

With inductance (line choke), the peak amplitude of the current is reduced to a range of 3 to 5 times the RMS value. This means a lower ripple current in the DC bus of the motor control. This reduces heating in the capacitors and effectively extends the lifetime by a factor of two.

Voltage and current with the harmonic filter THDI < 8%

With the harmonic filter, the line-side current is sinusoidal.

The peak amplitude of the current is 1.4 times the RMS value. The filter output provides a nearly ideal rectangular voltage and current waveform into the motor control resulting in diode conduction of almost 180 degrees.

The voltage on the DC bus is practically flat, and the DC bus capacitors see minimum ripple current, resulting in a further extension of life to 3+ times the nominal.

Furthermore, the average voltage value of the DC bus does not sag much compared to the first two cases. The result is more motor torque at higher speeds.