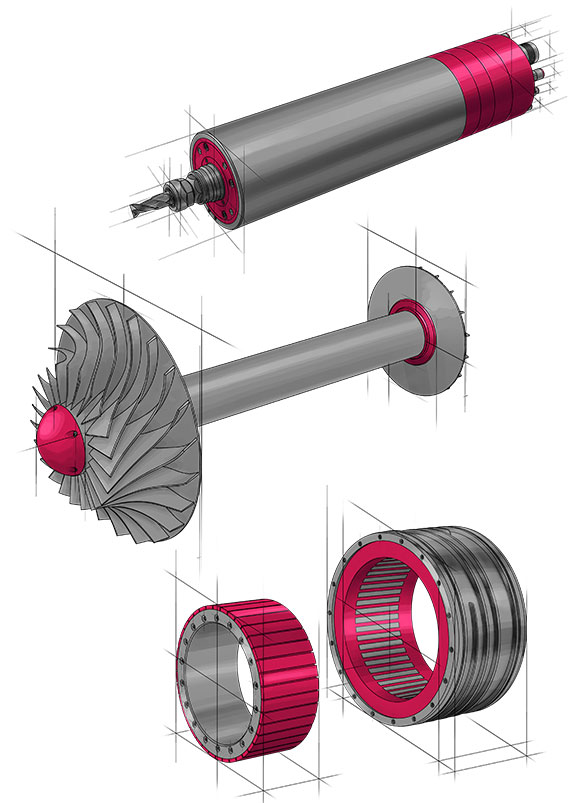

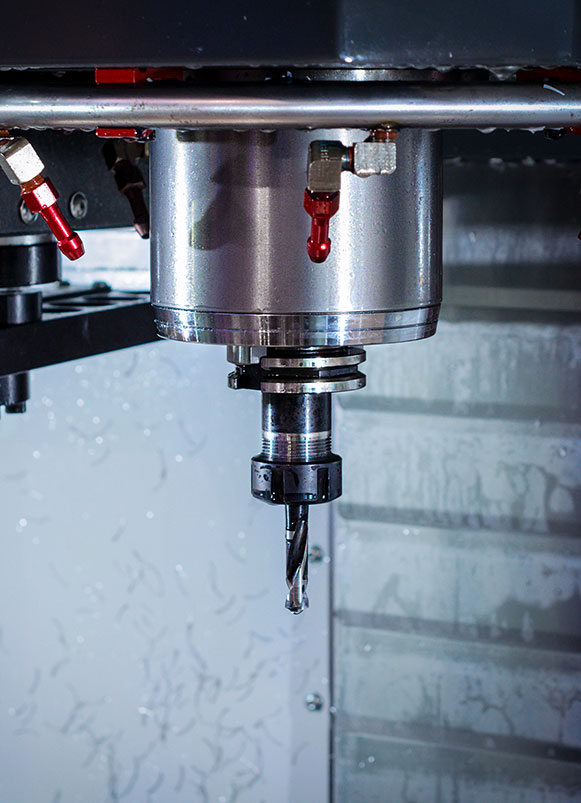

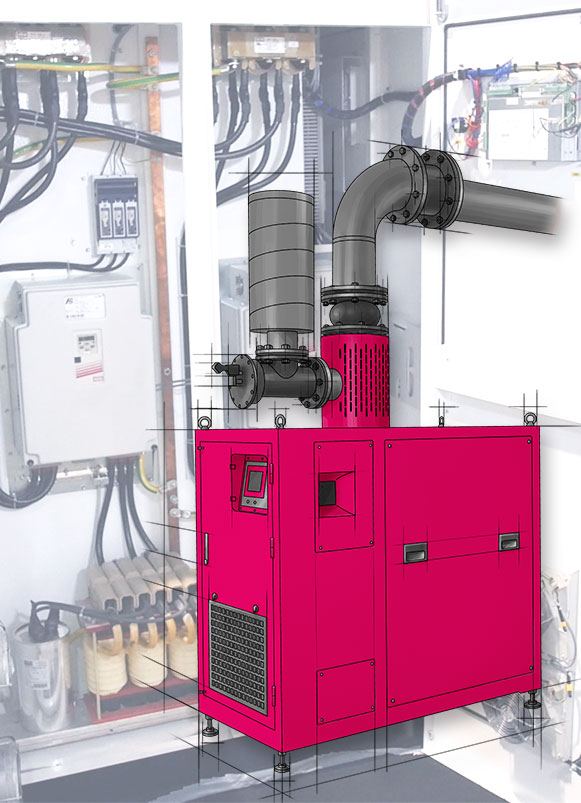

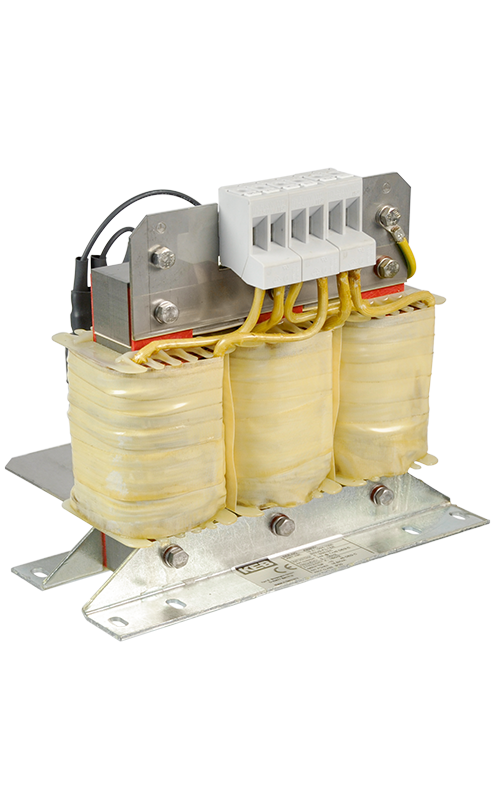

With over 500,000 installed spindle drives, KEB has solidified its position as a global leader in high-speed motor control. Our expertise and innovative solutions have made us the preferred choice for numerous CNC, woodworking, and robotic companies.

KEB's commitment to innovation has made us a trusted partner for industries that demand precision and reliability. Our solutions cater to the needs of those seeking high-speed spindle motors for CNC applications, ensuring optimal performance and efficiency.