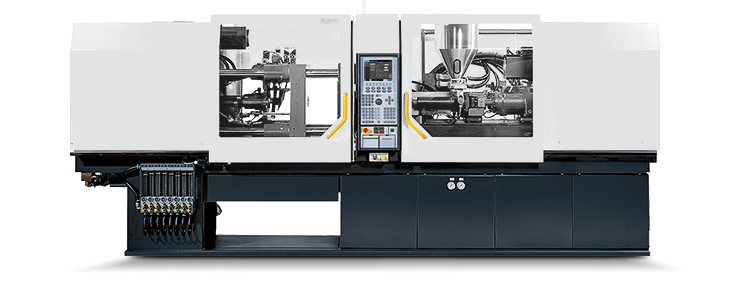

KEB is found inside the leading Injection Molding and Extrusion machines globally. KEB drives and controls provide dynamic, reliable, and repeatable performance. The KEB performance advantage is obvious when you look at the final product: more throughput and better quality.

Plastics

Plastics Machinery Applications

For more than thirty years, KEB has been at the forefront of delivering motor control solutions tailored for plastic machinery applications. Our offerings boast advanced features, adaptable software, and versatile hardware choices, empowering machine builders to design machinery that excels in performance, efficiency, and dependability. With a global presence, KEB solutions are integrated into various plastic machinery types worldwide, including extruders, injection molding machines, as well as related equipment like processing units and recycling shredders.

Precise Speed and Torque Control

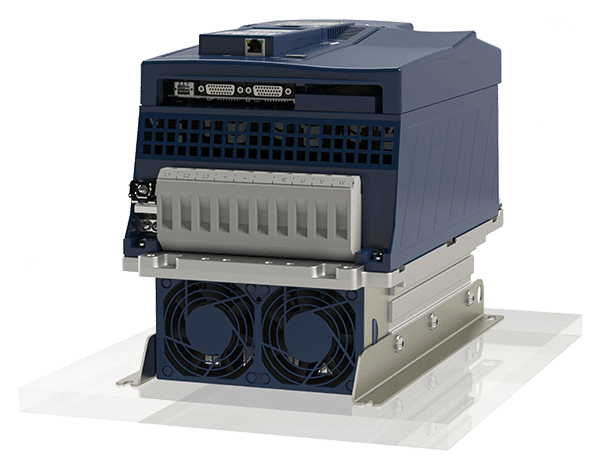

The KEB F6 Inverters excel in motor control, offering unparalleled precision in managing speed and torque alongside remarkable dynamic response. With swift control loops, they guarantee speed and torque accuracy within a margin of less than 3%, ensuring consistent quality in extrusion and injection molding screw applications, while also optimizing cycle times for repetitive machine tasks. These superior standards are achievable through both standard closed-loop vector control and innovative "sensorless" motor control methods.

Large Power Sizes

KEB boasts a diverse portfolio encompassing a wide range of power options for both inverters and motors, including exceptionally high-power solutions. The F6 Inverters span from 0.75 kW to 450 kW (up to 1.2 MW in parallel configuration), while our DL4 series offers high torque PM servo motors with nominal torque reaching up to 520 Nm (880 Nm peak), and our BT series provides torque motors with nominal torque capabilities up to 650 Nm (1,125 Nm peak). This extensive array of power options positions KEB as a single-source provider, catering to various machine functions ranging from low-power processing equipment to high-power screw drives.

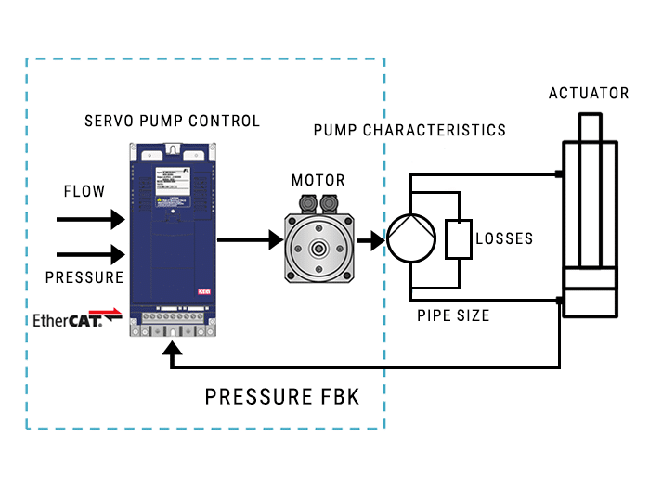

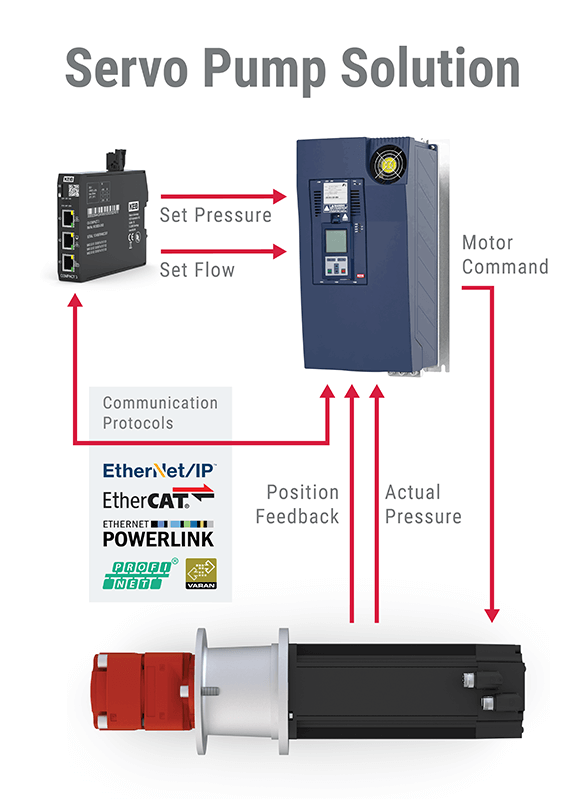

Servo Pump Solution

In hybrid electro-hydraulic injection molding machines, KEB F6 Inverters come equipped with built-in servo pump controller software, enabling precise regulation of pressure and flow. This innovative feature replaces conventional hydraulic systems with "on-demand" and variable torque/speed control mechanisms, leading to substantial energy savings by eliminating the need for relief and control valves. Additionally, the servo pump software offers programmable profiles tailored to enhance the performance of specific machine functions, thereby optimizing cycle times.

Sensorless Motor Control

The KEB F6 Inverters integrate advanced "sensorless" control algorithms, leveraging motor current and voltage measurements as feedback for closed-loop performance, eliminating the necessity for a motor encoder. This streamlined approach reduces system complexity and costs, including those associated with cables. Furthermore, it eradicates a potential point of failure, enhancing machine uptime and reliability. By circumventing issues like electrical noise, vibration, or temperature fluctuations that can affect encoders, these inverters ensure consistent performance and durability.

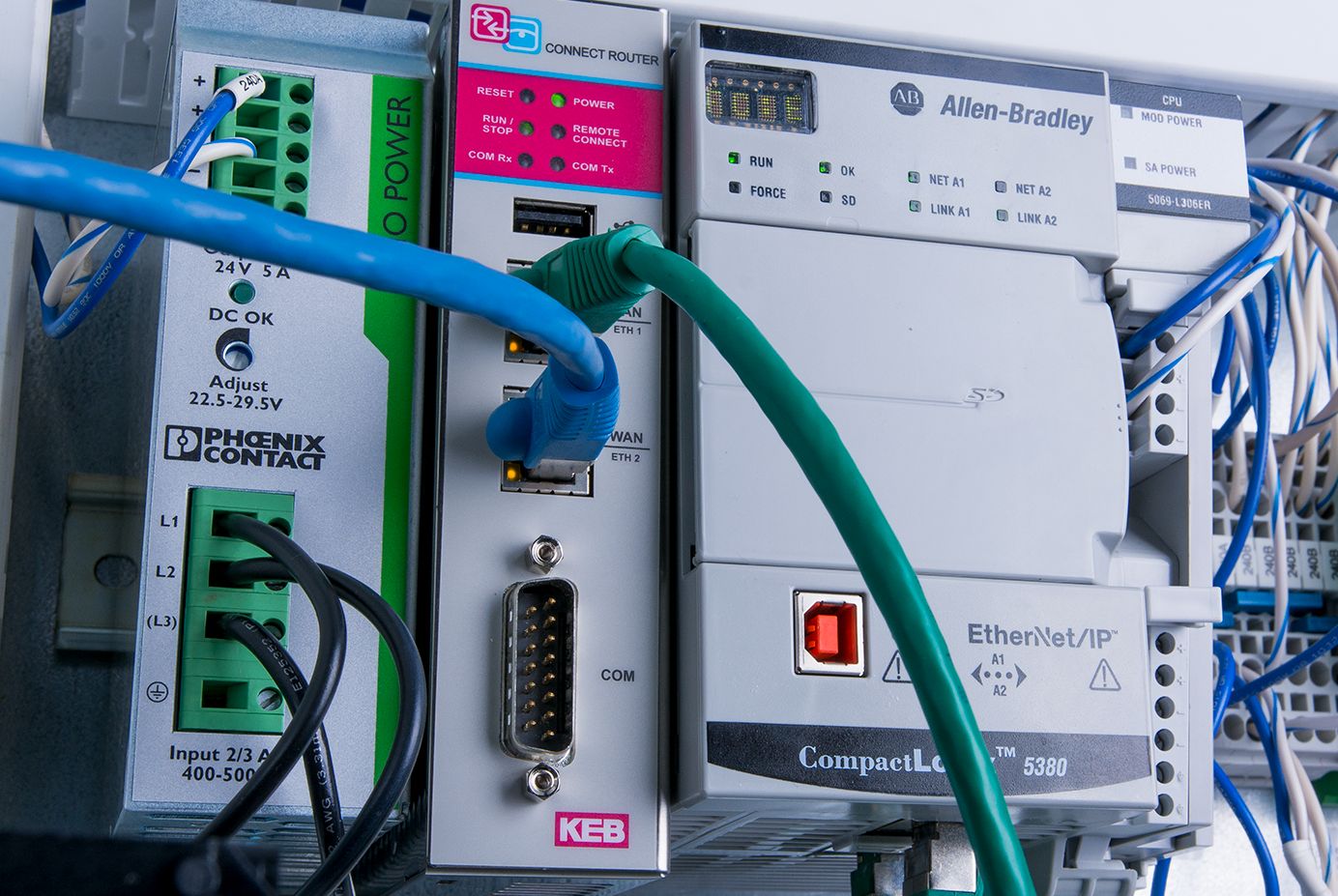

Panel Solutions

As a comprehensive system solution provider, KEB offers a full range of automation components for control panels, including the panels themselves! Our panel solutions are UL508A listed and come complete with required breakers. Furthermore, we provide a variety of additional component options such as filters and chokes, embedded controllers, I/O and safety modules, HMIs and panels, and routers. Complete panels serve as an excellent choice for sizable extruder screw drive systems or other large-scale equipment within the plastics industry, such as recycling shredders.

Protection Functions

The KEB F6 Inverters include multiple protection functions to safeguard equipment. These include blockage detection and torque limits to protect screws, reverse speed limitations to prevent pump cavitation, and jog mode with fieldbus bypass for manual operation and maintenance purposes.

The Future in Plastics Machinery Automation

As a global leader in control and automation technology, KEB leads the way in versatile, complete solutions for plastic machinery. Our innovative controls, drives, extrusion, and injection molding systems provide the ultimate in automation performance and flexibility for machine builders.

Controls for Plastics Machinery

KEB America offers embedded and Intel-based Industrial PCs for all plastics machinery, from mixers to injection molding machine control. These scalable control technologies are EtherCAT masters that provide real-time motion control for reliable and seamless machine operation. With options for resistive or capacitive touch, KEB Panel PCs are ideal controls for your industrial plastics machines and applications.

Drives for Plastics Machinery

KEB offers over three decades of experience in Plastic Drives applications, providing flexible options to match your unique requirements and needs. Our common drive technology offers world-class performance and is scalable with different communication protocols. This advantage empowers machine builders to support fewer product variants and achieve better serviceability across machines.

KEB drives for plastics machinery are also compatible with a wide variety of motor types, allowing machine builders to leverage the best motor technology for their needs without increasing design complexity. Our drives run the following motor types:

- Induction

- IPM & SPM AC Servo

- Spindle

- Torque

- Compact Motor Gear

- Synchronous Reluctance

- Linear

KEB Extrusion for Plastics Machinery

KEB offers a range of technology solutions for extruder machine control, including our industrial PC platform: Combivis Studio 6 IDE. This all-in-one Integrated Development Environment (IDE) includes a host of reliable tools to support the entire project lifecycle for plastics machinery, from prototyping to commissioning and support.

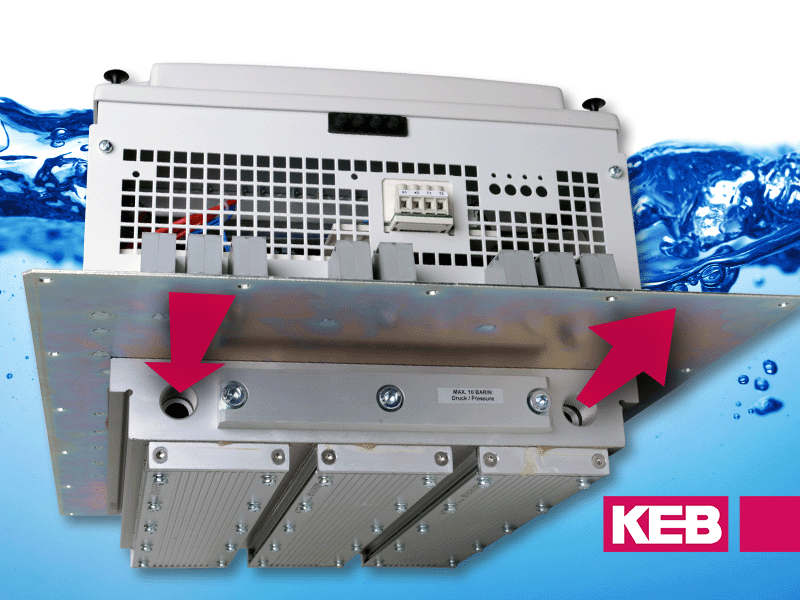

KEB’s applications extruders offer large power and versatile features to support your unique machine’s needs—including the latest IGBT technology for compact drive sizes, standardized functional safety, and air and liquid-cooled availability.

Injection Molding for Plastics Machinery

KEB’s H6 multi-axis drive offers unmatched performance across all-electric injection molding machines. This solution supports a range of cooling options, module sizes, and safety modules—allowing customers to craft the ideal drive system for their unique installation.

Our motion control products for injection molding include KEB drives, servo motors, and planetary gearheads, which allow machine builders to minimize cycle times through dynamic control capabilities. We can also support your building efforts with internal positioning modules to sequence motion profiles—as well as servo pump control solutions to optimize system efficiency, lower operating costs, and improve throughput.

Let's Talk

KEB has helped our customers solve many automation challenges. Let’s discuss your challenges and goals and see how we can help.