KEB has earned a reputation for controlling high-speed motors used on turbo blowers and power generating systems. High speed motors can operate in excess of 100,000 rpm and typically use airfoil or magnetic bearings. Given the elevated speeds, precise control becomes imperative to mitigate vibration and prevent motor overheating.

Turbo Compressors & Blowers

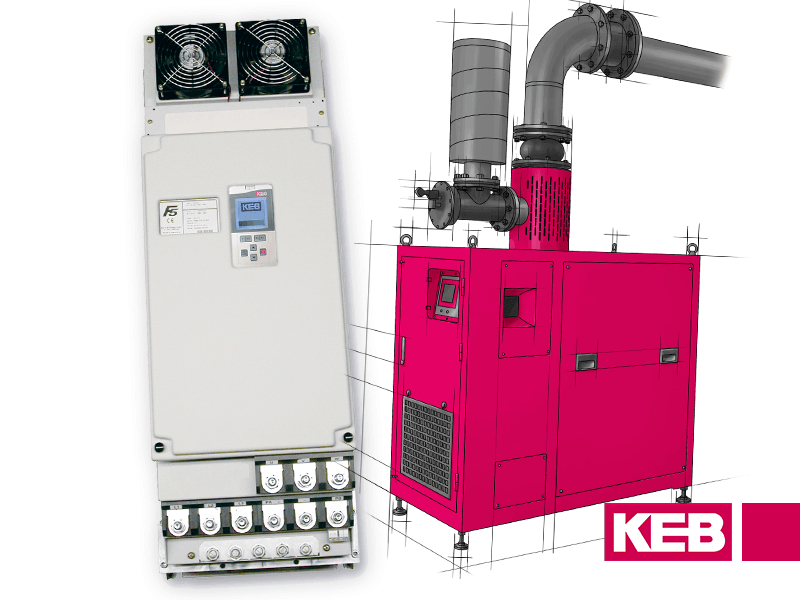

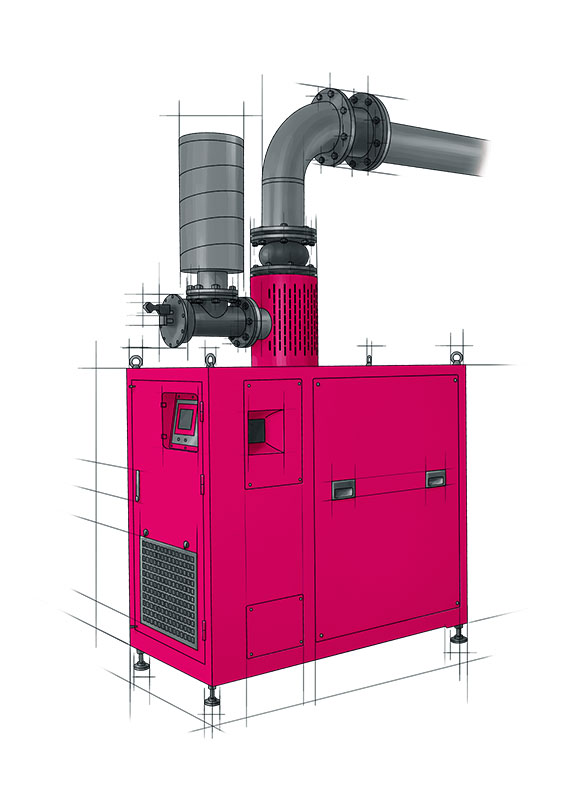

COMBIVERT F5 Drive

High speed applications are very demanding applications for VFDs. They require extremely stable motor control algorithms with very fast control loops. KEB’s VFD portfolio including the F5 drive meets all the requirements for high speed blower, compressor, and chiller applications. An important differentiator in this application is also KEB’s large installed base and application experience.

Efficient Solutions for Turbo Compressors & Blowers

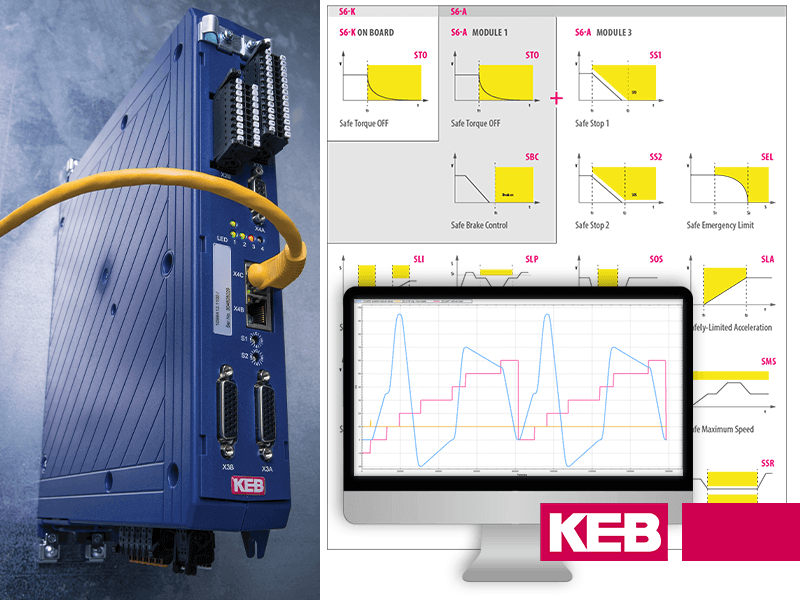

Tailored for the most challenging applications globally, KEB Variable Frequency Drives (VFDs) are particularly well-suited for high-speed turbo compressors and blowers. The KEB F5 drive offers configurable safety features, encoder interfaces, heatsinks, and communication ports, providing a comprehensive set of options to complement and enhance your high-speed motor applications.

KEB’s F5 drive incorporates an advanced control card, available in three performance tiers: Basic, Compact, and Application. It is offered in 230, 480, and 690 VAC classes, supporting up to 1,200 Hp. Additionally, the platform provides high-speed outputs, reaching up to 2000Hz, catering to the operation of high-frequency motors. This level of customization empowers machine builders to craft precise, tailored drive solutions that align with their specific application requirements.

Complementing the F5 drive, KEB Sine filters are accessible to enhance efficiency in turbo compressors and blowers by reducing rotor heating, limiting high-frequency transient emissions, and improving EMC load. This combination of control and automation solutions not only brings about notable efficiency gains but also ensures that high-speed motor applications operate more smoothly, functionally, and safely.

The Future in High-Speed Motor Technology

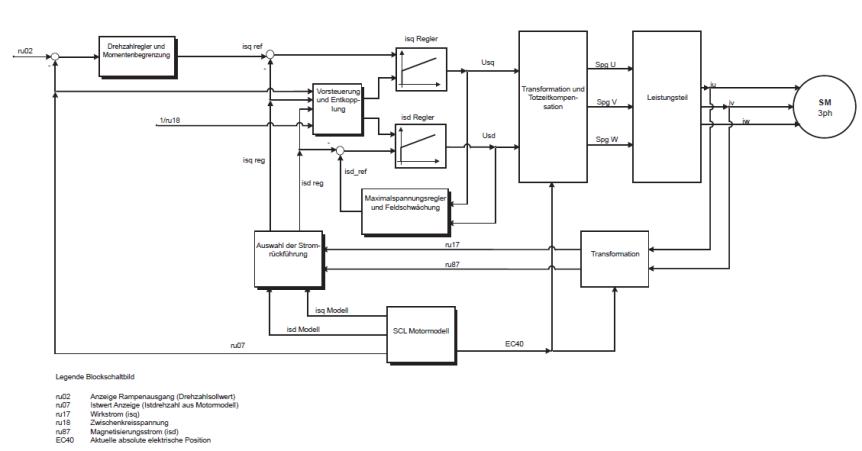

KEB high-speed motor technology brings precision control to high-speed, high-frequency applications, reducing vibration and motor heating. Limiting motor heating plays a significant role in optimizing system efficiency and maximizing the service life of bearings and motors in turbo compressors and blowers.

The advantages of KEB drives include increased performance via enhanced motor current quality. KEB drives help improve system reliability through powerful safety functions and reduce system costs across the product life cycle. The result? More stable, long-lasting, and dependable motor operations.

Customers choose KEB for flexible, easy-to-use control and automation products customized to fit their unique challenges and application needs. Our adaptable, turnkey solutions for high-speed, high-frequency motors can help you set a new standard in performance for turbo compressor and blower technology.

Let's Talk

KEB has helped our customers solve many automation challenges. Let’s discuss your challenges and goals and see how we can help.