Customizable Inverter Application Programs for eMobility Auxiliaries

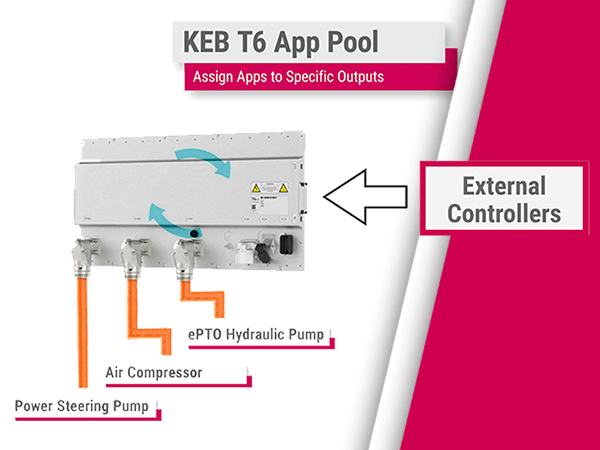

The KEB T6 Auxiliary Inverter offers several useful application programs, called “apps,” which can be used to add functionality and simplify inverter setup.

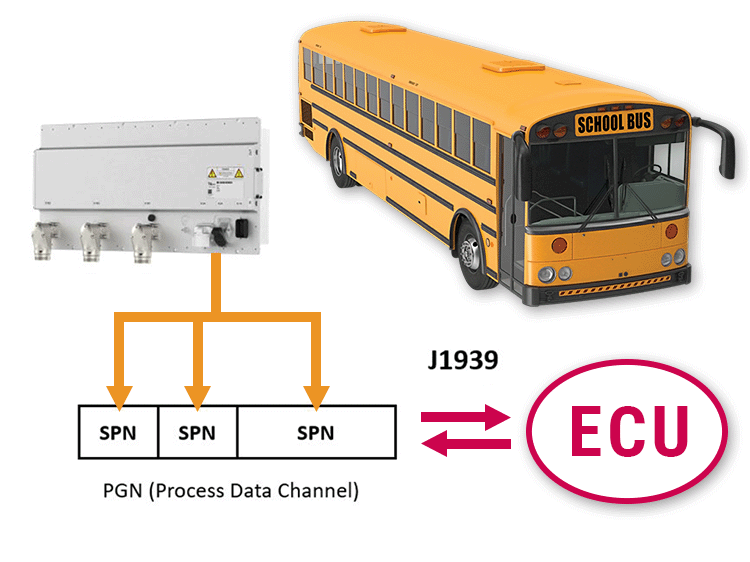

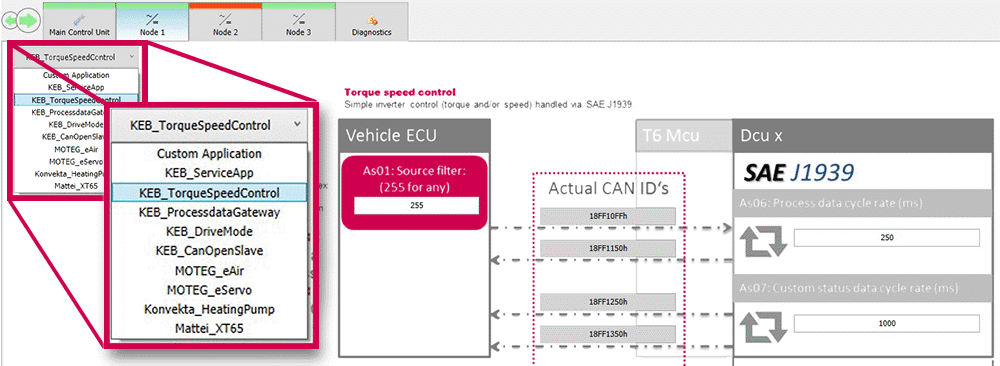

In addition to general-purpose apps created by KEB (i.e., Torque Speed Control, J1939 Process Data Gateway), third parties can develop custom application programs. Such functions can range from simple test routines to highly-specialized modes of control.

Read more: What’s an App? Understand the App Utility Framework

Read more: What is the Torque Speed Control App?

Read more: What is the J1939 Process Data Gateway App?

Why custom apps?

Customizable inverter apps allow developers to create innovative controls solutions with advanced functionality. Even if a desired function is not directly supported by the inverter control itself, an “app” can be created to support it. An app allows OEMs, system integrators, and auxiliary suppliers to leverage their system or product know-how to develop proprietary solutions that differentiate their product offerings with value-added features. Furthermore, the developer can also license proprietary custom apps for exclusive sale and distribution.

How are custom apps created and implemented?

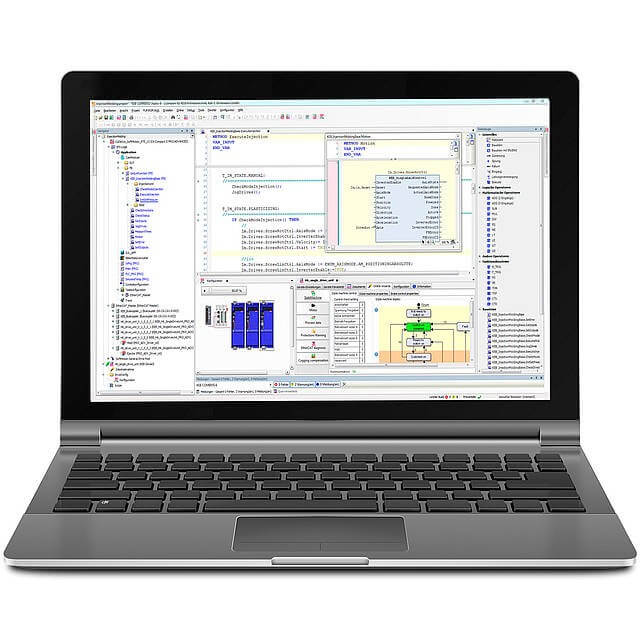

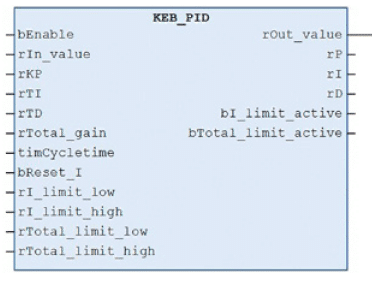

As part of a T6 system is an onboard embedded controller supported with KEB’s Combivis Studio, a freely-programmable CODESYS-based (IEC 61131-3 ) development environment for creating logic control programs. Similar to working with a PLC, a familiar visual graphic (ladder, function block, function charts) and text-based (structured, list) programming languages can be utilized. Extensive toolboxes and function module libraries are available to create application programs.

Read More: KEB Control and Automation Solutions

KEB has also developed an App Utility Framework for the embedded controller, which acts as an operating system to support and host application programs. The framework supports customizable inverter app development by providing a user interface structure. For example, application I/O variables can be assigned to open parameters addresses (similar to assigning functions to pins on an IC) for user access to make parameter adjustments and view diagnostics data. These parameters can be linked to graphical interfaces to create intuitive startup wizards.

Once an application program has been created, it’s included in an App Pool where all available apps are hosted. It becomes a selectable option for each inverter stage of a T6 system (although a license may be required for operation).

Use Case Examples

There are a lot of possibilities of what could be realized with custom application programs. This can range from simple control loops for setpoint regulation to in-depth control algorithms based on multi-faceted system models for optimized efficiency or performance.

Custom application programs can be applicable for various applications and use cases. To provide some context, consider the following use case examples:

Basic Example – HVAC Temperature Regulation

A custom app could be created for the temperature setpoint regulation for compressors or heat pumps in HVAC applications. Rather than sending the inverter a motor speed command, the setpoint and actual temperature values could be sent and used with an internal control loop to operate the motor and regulate the temperature accordingly.

This is a basic example, and the HVAC supplier likely has a control solution in place. Although, generally, this type of functionality could be off-loaded from an ECU and instead implemented on the T6 embedded control as a custom app (including diagnostics sent to VCU) and potentially eliminate an auxiliary ECU.

Advanced Example: On-Demand Power Steering – Energy-Saving and Low Noise

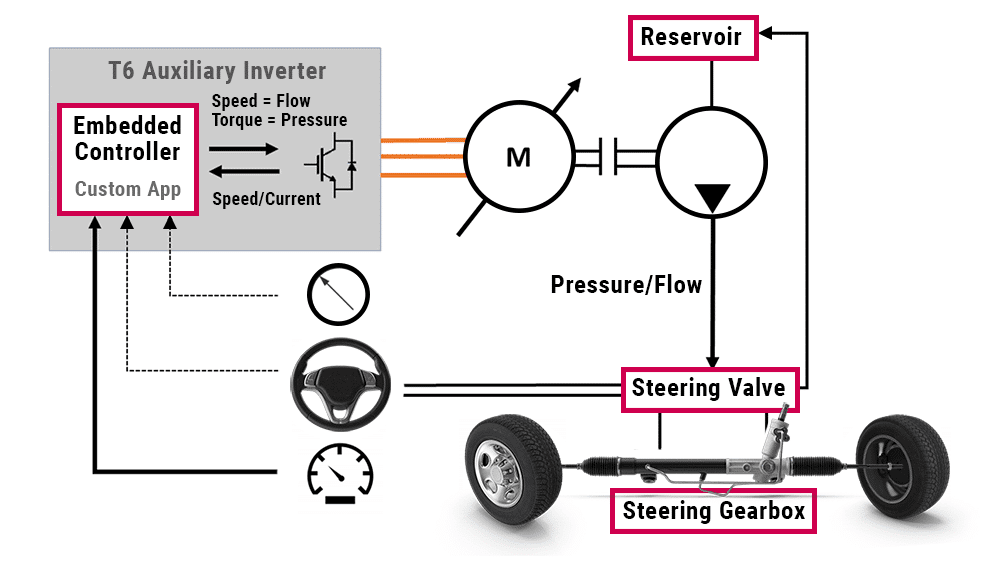

Electro-hydraulic power steering (EHPS) applications are an excellent candidate for implementing smart control solutions utilizing a custom application program.

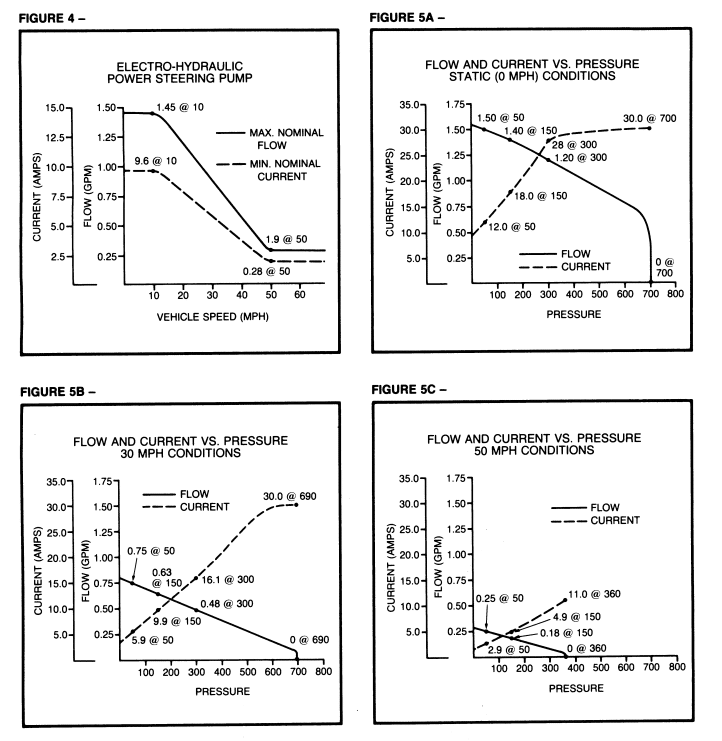

An electric motor drives a hydraulic pump to provide assisted steering torque in these applications. The amount of steering assist needed largely depends on the vehicle speed, with high amounts of assist needed during low-speed parking and maneuvering, minimal assist needed at high speeds, and no assist needed during idle non-steering operation (although, minimal pressure is required to account for parasitic losses).

Here, an “on-demand” variable assist solution based on vehicle speed could be developed, which only operates the motor when needed and only with the required power. Thus, compared with conventional hydraulic steering, energy consumption and the audible noise of the pump would be significantly reduced.

Source: Electrohydraulic Power Steering — An Advanced System for Unique Applications

Author(s): James E. Forbes, Steven M. Baird and Thomas W. Weisgerber

Source: SAE Transactions, Vol. 96, Section 2 (1987), pp. 758-766

Read More: Electrohydraulic Power Steering Pursued for Heavy-Duty Vehicles

In this EHPS example, a custom application program could use the vehicle speed as an input to determine the amount of steering assist needed and calculate the motor speed command corresponding to the flow needed to create the additional pressure. Although this concept is well known, the know-how is in the implementation.

Exactly how this control algorithm would be modeled allows the developer to create a unique, proprietary solution for their customers. And beyond the vehicle speed, other conditions (steering sensors, pressure sensor, motor current, oil temperature, etc.) can also be considered and incorporated into the model for additional performance or value-added features such as adaptable steering maneuverability (“feel”) based on road surface conditions.

In addition to power on-demand solutions for power steering, such programs can be created for electro-hydraulic pumps in body equipment, mobile machinery applications, and air compressors in brake and suspension applications.

Modular add-on functionality

In addition to the core operational functionality of an application program, there is the possibility of creating modular add-on functionality.

- Startup Routine

- Oil warm-up

- Operating Modes

- Reduced/Low-Power Mode – Limit torque, reduce speed

- Diagnostic Test Routines

- Manual override of motor control, e.g., jog speed

- Communications test

- Communications

- Preconfigured CAN telegrams

- Implementation of new protocols, e.g., CAN FD, HSD, DoCAN

- Extended diagnostics services, e.g., additional UDS standards, DTC DMs

- Data Collection

- Analyze system performance

- Predictive maintenance

- Data logging

Contact KEB for Custom Inverter Applications

If an application requires functionality not readily available on the inverter itself which is auxiliary or application-specific or highly custom control, then a custom app can be developed to provide a solution. The possibilities are wide open.

If you have any questions or would like to discuss potential solutions, please contact a KEB Applications Engineer to discuss your application.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.