Electrifying Auxiliaries – Apps for Communication and Control

When choosing an inverter for the electrification of auxiliaries in commercial electric vehicles, most of the upfront attention is paid to the hardware specifications of the inverter, such as electrical and mechanical ratings.

While this is the first thing to consider to ensure a device meets the application’s technical requirements to operate properly, an oft-overlooked aspect of auxiliary electrification is the strategy for communication and control.

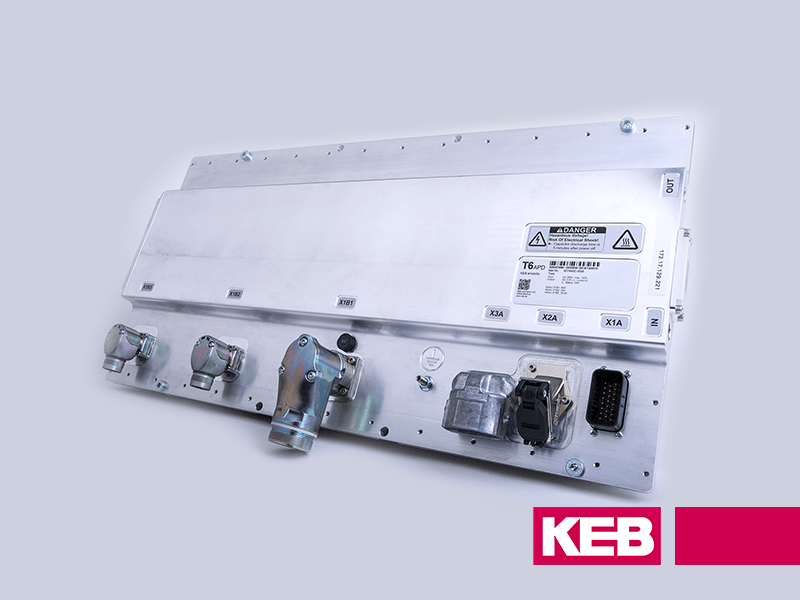

That is, how the vehicle system interacts with the auxiliary via the inverter, from both an operational and diagnosis standpoint. This is where software solutions come into play, and a unique feature of the KEB T6 Auxiliary Inverter is that it contains an embedded controller. The embedded controller serves multiple purposes, but a key feature is that it supports using application software programs, or “apps.”

What is an App?

To understand what an app is, it is important to explain the platform that the apps run on. The T6’s embedded controller runs an App Utility Framework, like an operating system on a computer that operates the hardware and provides a platform for application software to be run on.

Application software are programs that external users (including other controllers) interact with directly and are purpose-built to perform specific functions. Thus, they provide a simplified interface for carrying out tasks. Put simply, the concept of an app is no different than that of a computer program.

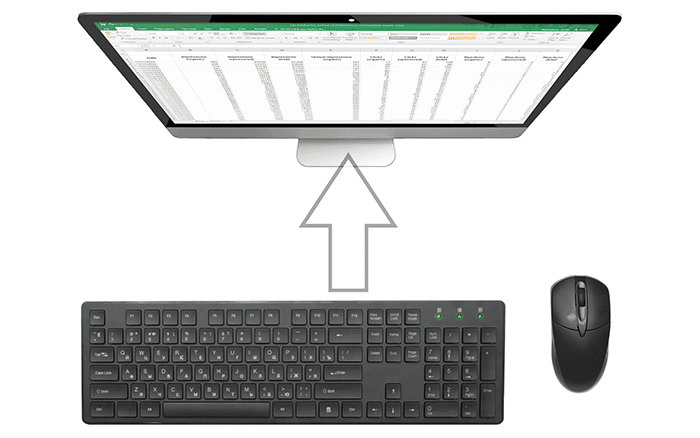

On a computer, such familiar programs would be spreadsheets or videoconferencing software. On an auxiliary inverter, this could be a specialized program that optimizes power steering control based on driving conditions or a program which acts as a CAN communications gateway.

As a further example, consider a basic spreadsheet program on a PC. The keyboard (ECU) and monitor (inverter) cannot perform the function of a spreadsheet on their own. The spreadsheet program (app) is required to process the keyboard’s inputs, perform the necessary function, and then route the outputs to be displayed on the monitor.

Types of Inverter Apps

Apps can range from basic to advanced functionality, from pre-configured to fully flexible. In any case, apps generally serve two primary roles in a T6 Auxiliary Inverter system: Facilitating communication between the ECU and the inverter(s) and controlling the motor driving auxiliary.

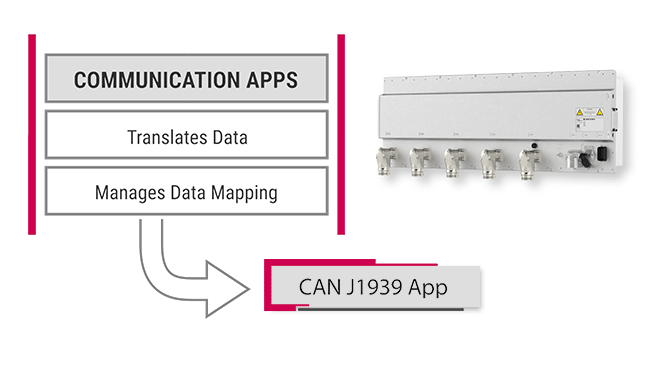

1. Communication Apps

Like a network gateway, communications apps translate protocol and manage data mappings. J1939 is the most common protocol for vehicle applications, although this isn’t the inverter’s native internal protocol. Therefore, apps can support CAN J1939 communications or protocols such as CANopen or ISOBUS.

For example, a J1939 communications app would parse telegrams received from the CAN bus and map the data to corresponding inverter parameters with the appropriate scaling and offset. Likewise, transmit telegrams from the inverter would include the data and partner addressing formatted according to the J1939 protocol structure (including transport protocol processes, as needed). Thus, there is no need to “speak” the inverter’s language or be familiar with specific parameter locations and settings. The app handles this to make the communication implementation seamless.

An additional aspect of communication apps can also include diagnostics, such as the J1939 diagnostic trouble code message services (e.g. DM01-04) or Unified Diagnostic Services (UDS) according to ISO 14229-1 standard.

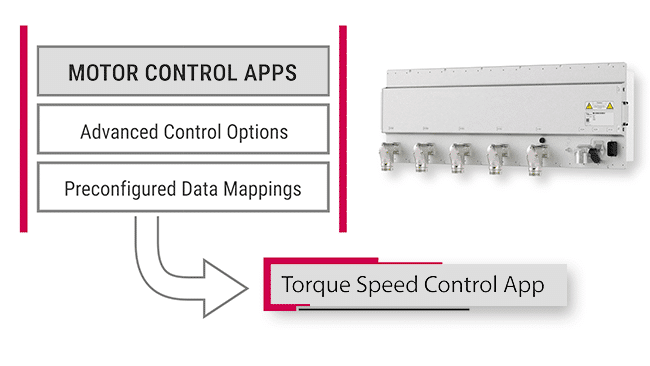

2. Auxiliary and Motor Control Apps

The operation and performance of an auxiliary go hand-in-hand with the control of the motor driving the system. Control apps can serve several purposes, such as providing a means for simplified setup, efficient operation, increased performance, and/or the capability of advanced functionality.

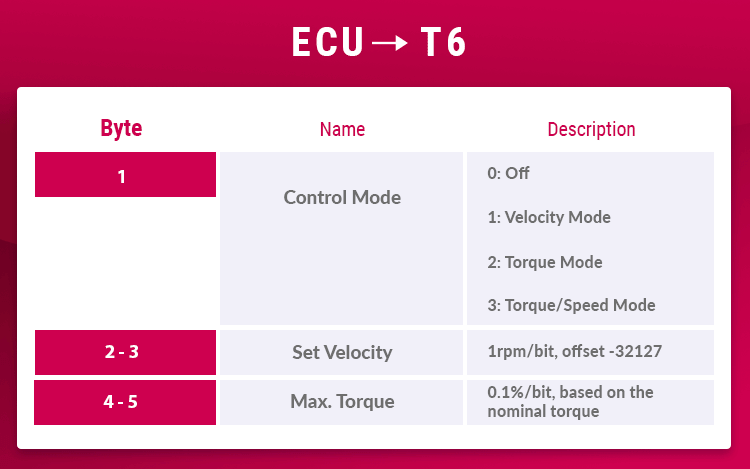

The commonly used Torque/Speed Control app is an example of a basic control app. This app simplifies setup with a pre-defined control telegram where the speed or torque control mode is selectable with a single setting (a combination of both is also available).

Based on this setting, the app configures the corresponding inverter settings to operate in the selected mode. The telegram also contains fields for the speed and torque setpoints and likewise maps these accordingly. Thus, with the Torque/Speed Control app, a user could operate the motor in these modes with minimal setup.

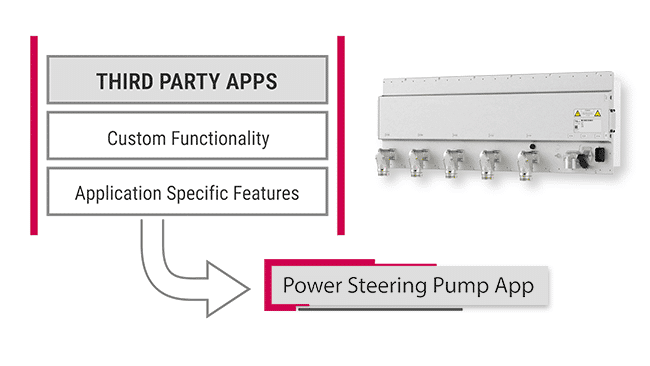

More advanced control apps are often exemplified by custom, third-party apps developed by auxiliary manufacturers, system integrators, or vehicle OEMs.

Third-Party Apps and Advanced Functionality

In addition to the general apps provided by KEB, third parties can utilize the App Utility Framework as a basis for developing their apps. The T6 embedded control supports a CODESYS-based programming environment which allows developers to create (and license) proprietary application programs. Such apps can be specific to their product or system and provide custom features or advanced functionality.

For example, a power steering pump manufacturer could develop a “power-on-demand” app to operate the pump motor according to the expected pressure based on vehicle speed and steering angle. This type of control app operates the power steering system more efficiently, and this advanced functionality is an energy-saving feature.

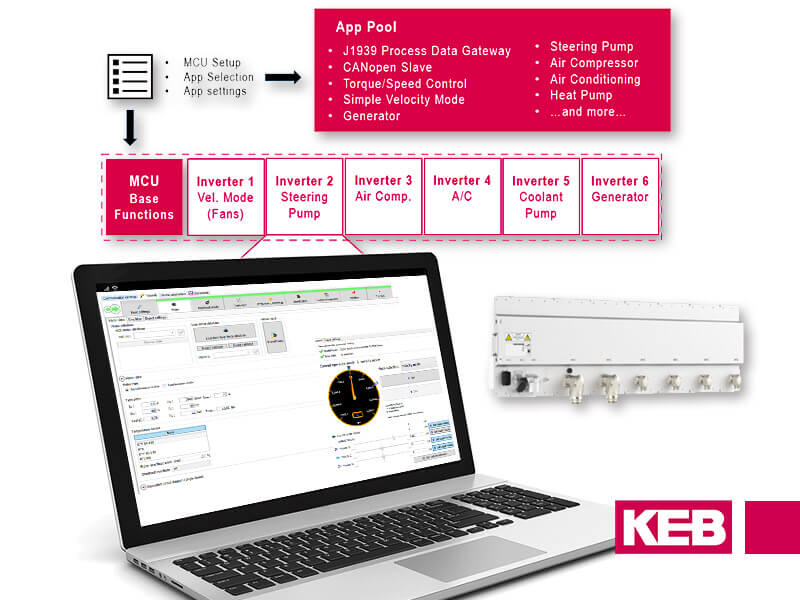

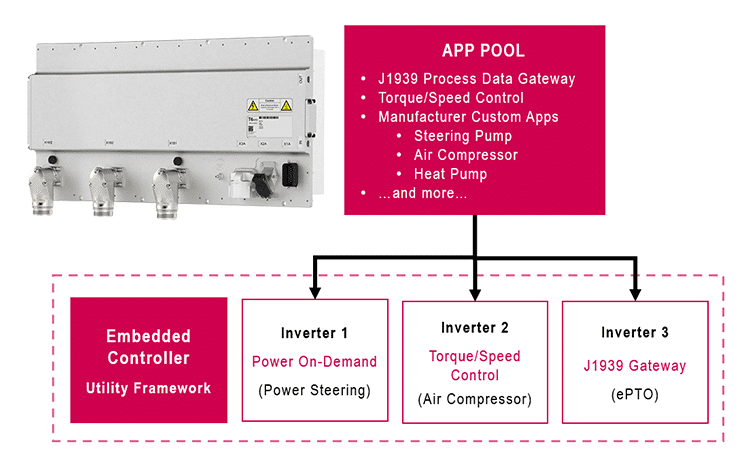

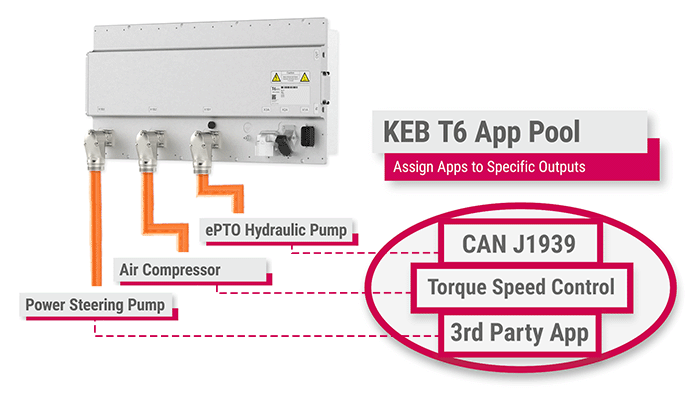

App Pool

Since the T6 system can be scaled to include multiple inverter outputs with independent control, the App Utility Framework also acts as a platform and contains an “App Pool.” This makes it easy for system integrators to select from the various apps available according to the requirements of each auxiliary.

For example, a T6 with 3 inverter outputs could be used to drive a (1) power steering pump, (2) air compressor, and (3) ePTO hydraulic pump for body equipment.

In this example, a system integrator may select a custom Power On-Demand app developed by the steering pump provider, the Torque/Speed Control app for basic variable speed control of the air compressor, and the J1939 Process Data Gateway app on the ePTO pump to provide them more flexibility on the broader range of body equipment applications.

Conclusion

The KEB T6 apps are useful tools for accelerating development time and implementing advanced functionality. The KEB T6 Auxiliary Inverter has a pool of apps ready to be implemented and the limitless potential to create new ones. Contact a KEB applications engineer to learn how apps can benefit your application.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.