Servo Motor Brakes – How they Work

Servo motor brakes play a critical role in various industrial and commercial applications. These brakes are carefully engineered to provide reliable stopping power in systems where precision is necessary.

The importance of these brakes becomes even more pronounced in environments where safety and accuracy are paramount, such as in automated manufacturing lines, robotics, and aerospace applications.

The unique design of these brakes, including their power-off spring-set feature, ensures that they engage effectively even in the absence of power, making them an ideal choice for fail-safe applications.

This fail-safe mechanism prevents equipment damage and ensures operator safety, particularly when unexpected power loss could lead to catastrophic failures.

By integrating these brakes into servo systems, engineers can significantly enhance the overall reliability and safety of their machinery.

KEB Servo Motor Brakes

KEB servo brakes are popular because they have low inertia, offer low backlash braking, and can operate at high speeds. This video describes how KEB spring-set servo motor brakes work.

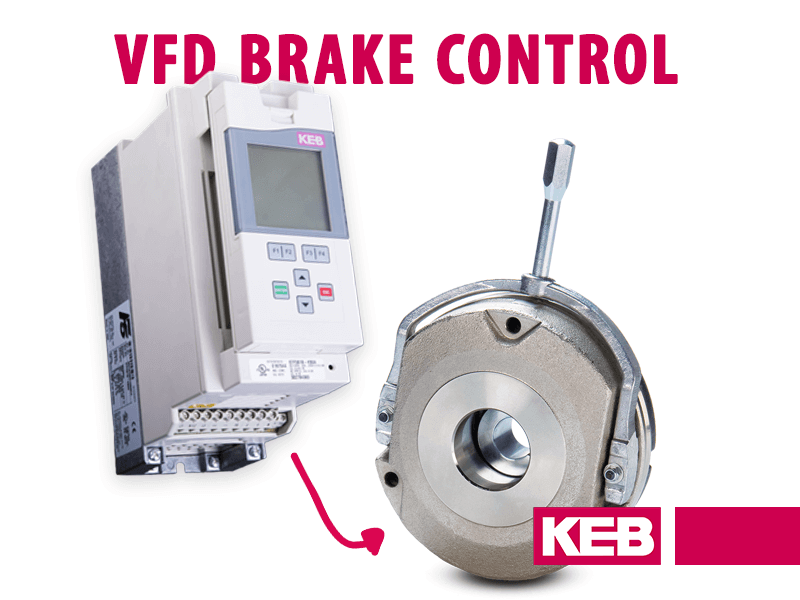

A magnetic circuit is created when an electromagnetic coil is powered with DC voltage. The magnetic field is strong enough to pull an armature into the magnet housing and compress multiple embedded springs.

With the springs compressed, the friction lining, hub, and shaft can rotate. When power to the magnet is released, the springs push against the armature. The friction lining is sandwiched between the armature and a secondary friction plate.

Because the friction lining is connected to the shaft with a splined connection, the shaft stops rotating and is held in place.

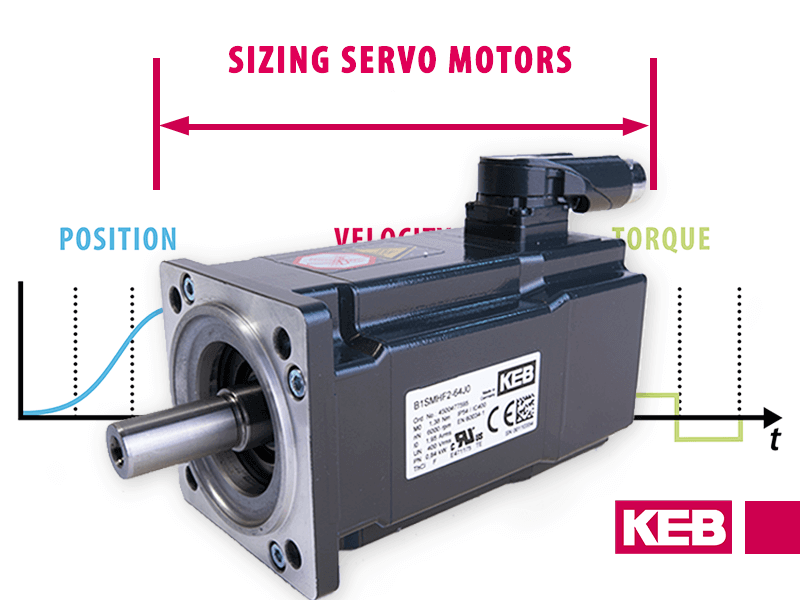

How Do Servo Motors Stop?

Servo motors, integral in line manufacturing and various control systems, achieve precise position control through a sophisticated mechanism. The stopping of these motors involves a dynamic interplay between the motor’s components and the control circuit.

When the servo motor controller issues a halt command, it modifies the electric signal sent to the motor, explicitly adjusting the pulse width to effectively control and stop the motor.

This change in signal directly affects the position of the shaft of the servo motor, whether it’s a DC servo motor or an AC servo motor.

In closed-loop systems, feedback mechanisms ensure the output shaft stops at the desired position with high accuracy and efficiency.

In addition to the control mechanisms mentioned, servo systems employ a variety of servo motors, each with its distinct characteristics and capabilities.

The position of the shaft is a critical aspect, determined by the control circuit and servo motor controller, which regulates the motor’s movement to achieve precise positioning. This positioning is crucial in applications where accuracy is paramount, such as robotics and precision tooling in manufacturing.

How Does A Servo Brake Work?

A servo brake is critical in servo systems, particularly in applications where precision and safety are paramount. The brake engages when the servo motor stops or loses power, ensuring the motor’s rotating ceases movement promptly.

This is achieved through an electromechanical process where an electric signal activates the brake.

In the absence of this signal, as in a power-off scenario, spring mechanisms force the brake to engage, thereby securing the position of the shaft. This functionality is vital in many servo motors, ensuring that the system retains its position integrity even during a power failure.

The servo brake’s role extends beyond just stopping the motor. It plays a vital part in maintaining the integrity and positioning of the motor’s output shaft, especially when power is unexpectedly lost. This ensures that the systems relying on these motors do not suffer from unexpected movement or loss of calibration, which can be critical in fields like aerospace or automated vehicle manufacturing.

Exploring Servo Motor Brake Applications

Servo motors, including DC and AC motors, are used in diverse applications, from robotics to manufacturing lines. The choice between a DC and an AC servo motor often depends on the application’s specific speed, torque, and precision requirements.

In servo systems, the role of the brake is not just to stop the motor but to ensure the accurate positioning and safety of the entire system. This is particularly crucial in applications like robotic arms in manufacturing or precision instruments in medical devices.

The servo motor brake engages in a fail-safe manner, ensuring that even during power loss, it maintains shaft position, preventing unwanted movement or drift.

Further exploring applications, servo motor brakes find extensive use in sectors where precision and safety cannot be compromised. In automated line manufacturing, for example, equipment’s exact stopping and holding are crucial.

The servo motor brake’s ability to maintain the position of the shaft even in power-off scenarios is invaluable in these settings.

KEB – Your Partner for Engineered Brakes

KEB offers power-off spring-set motor brakes designed specifically for various servo motors, including DC motors and AC motors, in applications requiring fail-safe braking. These brakes ensure servo systems’ precise control and safety, particularly in high-stakes environments.

Integrating servo motor brakes in servo systems enhances both the safety and precision of these systems. These brakes play a pivotal role in ensuring that the motors rotating come to a halt in a controlled manner, whether due to a command from the control circuit or due to a power failure.

The technology behind servo motor brakes, whether in DC motors or AC servo motors, exemplifies the advancements in engineering that continue to push the boundaries of precision and reliability in automated systems.

KEB’s commitment to innovation in servo motor brakes is evident in its continuous research and development efforts. By understanding and adapting to the evolving needs of various industries, KEB ensures that its servo motor brakes meet the highest standards of efficiency, reliability, and safety.

Whether for a DC servo motor or an AC servo motor, KEB’s engineered brakes are at the forefront of technological advancement, offering solutions that cater to the ever-increasing demands of modern automated systems.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.