KEB Servo Pump System for Molding and Press Machines

In the fast-paced world of modern manufacturing, where every second and every micron matters, molding, and press machines are at the heart of the production process. Their ability to shape and mold materials with precision is essential across a wide range of industries.

To maintain a competitive edge and meet the growing demands of quality, speed, and sustainability, these machines require an upgrade in their power systems. Enter KEB’s servo pump system for molding and press machines.

By combining the precision of servo motors with the power of hydraulic pumps, these systems not only boost productivity and accuracy but also bring about significant energy savings, reduced maintenance costs, and a more environmentally responsible manufacturing process.

Reliable Mold Pressure

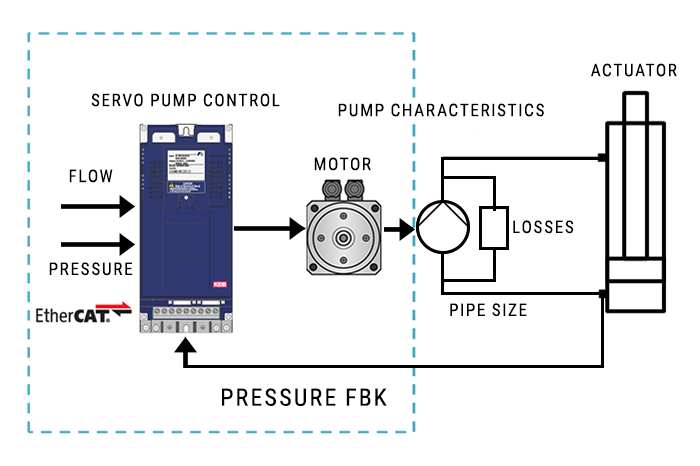

KEB’s servo pump solution is used on hydraulic systems where a pump, driven by a servo motor, controls the hydraulic fluid flow. The alternative, less efficient approach is managing the hydraulic fluid flow with several valves. The servo pump gives the machine more precise and efficient control over the fluid flow and pressure on the mold or press.

Variations in mold pressure result in product defects and/or non-uniformity in the final shape. These variations cause a loss in profits for several reasons in order from least severe to most:

- The defects are caught in QA, and the plastic is recycled into the system. This result causes minimal harm, but production efficiency decreases as fewer units are produced daily.

- The defects are caught in QA, and the plastic is discarded. This decreases the efficiency of production and results in raw material loss.

- The defects are not caught in QA and make it to the customer. Every time this happens, the customer loses confidence in the product quality produced by the manufacturer.

These cases are not all-encompassing, but all stem from pressure variations in mold pressure.

KEB’s servo pump system can minimize the occurrence of product defects stemming from variations in mold pressure. This is particularly important to injection molding machines and press users, as it directly impacts their time and bottom line. Moreover, original equipment manufacturers (OEMs) specializing in injection molding and press machinery should prioritize this feature, as it is a key performance metric valued by their customers and can ultimately influence purchasing decisions.

Advantages of a Servo Pump Over Conventional Hydraulic Fluid Control

Efficiency: The fluid pump runs constantly with a typical fixed pump and proportional valve hydraulic fluid control. In contrast, the KEB Servo Pump system activates the pump only when pressure is required, resulting in potential energy savings of up to 70%.

Noise Reduction: Since the pump is not running constantly in a Servo Pump system, there is less ambient noise from the machine.

Reliability: Instead of several conventional valves, you have one reliable KEB servomotor in the hydraulic fluid circuit. This results in less downtime/more productivity.

KEB Servo Pump System Components

Drive: KEB’s S6 and F6 drives are designed with servo pump control in mind. They both program the same way, and the S6 covers applications from 0-7.5kW while the F6 covers 7.5kW applications up to 900kW. They come with dual channel STO as standard and have an option for additional safety functionality with SiL3-rated safety functions such as Safe Door Control.

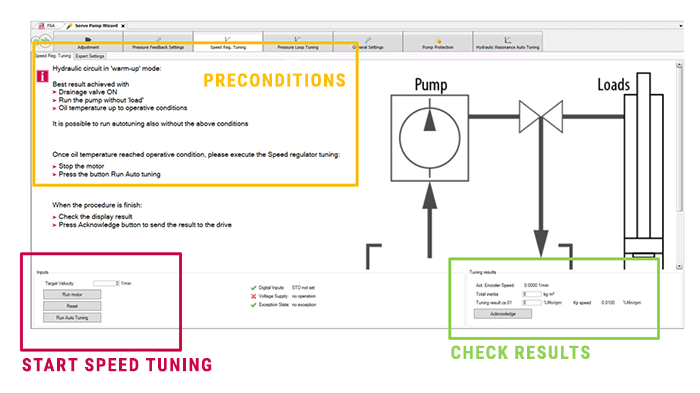

Additionally, for the servo pump application, KEB has created programming wizards to help programmers easily get the servo pump system up and running:

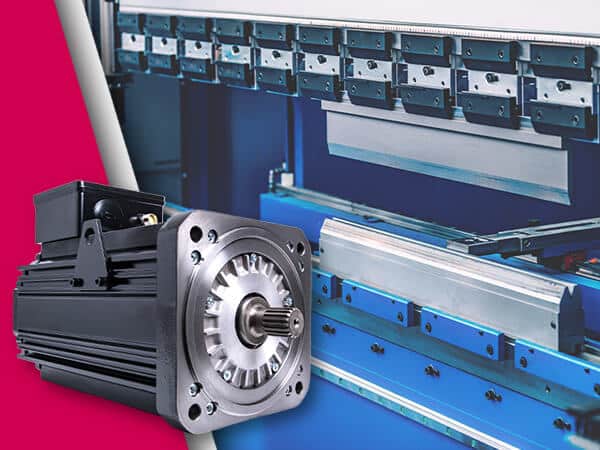

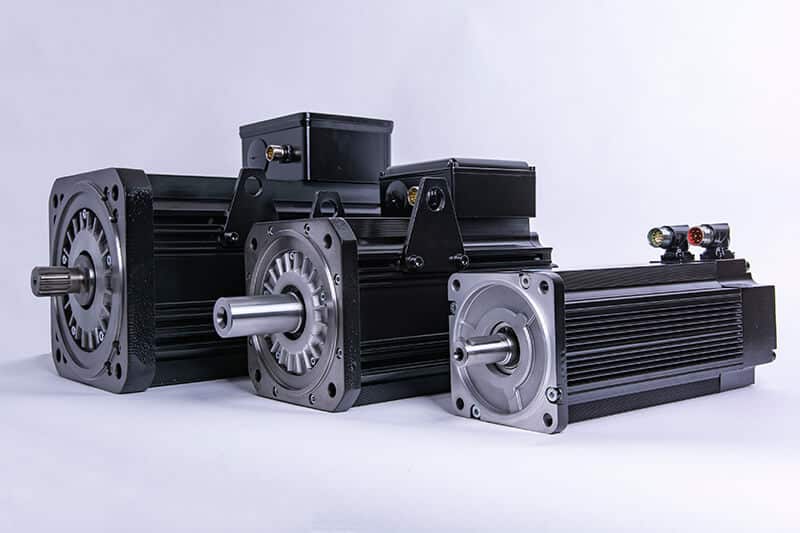

High Torque Servo Motor

Servo Motor: KEB’s servo motors range from 0.4-530Nm. This range was recently increased with our DL4 series high torque servo motors. These are highly customizable and are available with liquid or natural cooling. Since liquid cooling is typically available on plastic machines, our liquid-cooled DL4 motor is a perfect driver of a hydraulic fluid pump.

KEB Servo Pump System Features

A KEB servo pump system offers precise control with little complexity.

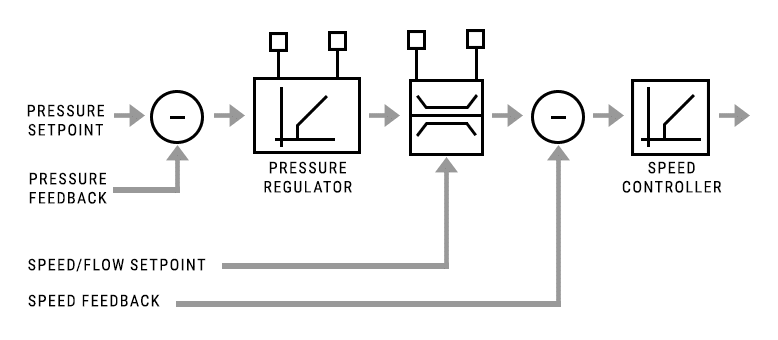

The scan time for current control loop in a KEB drive is 250µs. This, coupled with our adaptive gains, allows the drive to reach the pressure setpoint quickly and accurately with little or no overshoot. To adjust the pressure, our F6 drive generates a speed command limited by the speed/flow rate setpoint.

The problem with using one servo pump for all hydraulic axes is the range of actuator sizes. The largest axis will be fed with the same pump controller as the smallest axis.

When setting the proportional and integral gains in the drive, this can be an issue if the largest axis is much larger than the smallest axis. For this reason, KEB has developed adaptive gains in our servo pump drive firmware. This allows the programmer to use up to 8 different gains settings that will change on the fly depending on what axis is being fed.

Contact KEB for Servo Pump Solutions

Controlling your hydraulic fluid flow with a servo pump yields many benefits, including increased efficiency, less ambient noise, and higher system reliability. KEB components for the servo pump control will give you precise and adaptable pressure level control. It will make programming easy with the Wizards in our Combivis 6 software. Contact a KEB application engineer with expertise in controlling hydraulic fluid pumps.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.