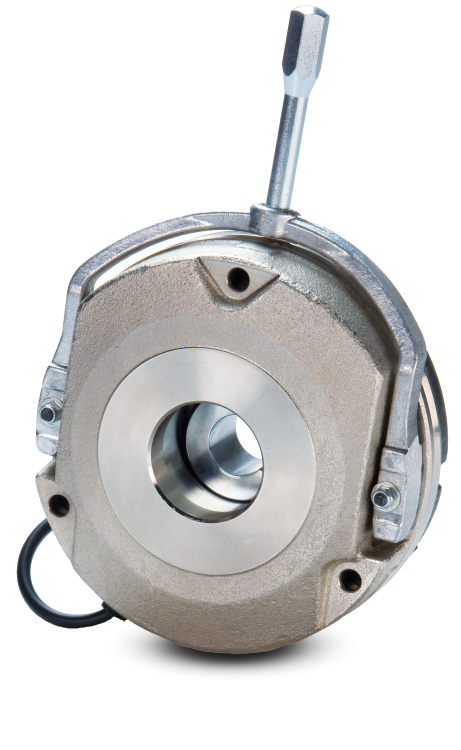

KEB America’s brake products are designed for DC (direct current) voltage. When looking on the market for power-off spring applied brakes, there are options for AC (alternating current) voltage brakes rather than DC. Both styles of brakes will achieve the same result of stopping the load, but the internal designs of the brakes are different causing advantages and disadvantages to both.

The internal differences change how they operate and how they can be implemented into machines. Ultimately, the supplied voltage is meant to create an electromagnetic field to attract a magnetic plate across an air gap and overcome the spring force to disengage the brake – see how our DC Spring Applied Brakes work. A brake can only be rated for AC or DC, so a list of the advantages and disadvantages of each technology is below:

AC Voltage Brakes

Advantages

- Faster reaction time

- Can run online voltage

- Single or three phase

- Will run cooler

Disadvantages

- Chattering noise

- In-rush current

- More common coil/solenoid failures

- Varying complexity of designs

- Lengthier UL process

DC Voltage Brakes

Advantages

- Quiet brake operation

- No in-rush current

- Can be battery operated

- Simple design

- Easier UL process

- 100% On Time

Disadvantages

- Slower reaction time

- Will run hotter

- Needs rectifier for line voltage

As you can see, there are some important differences between AC and DC brakes. Since KEB’s founding, we’ve believed that DC brakes are the best for any given application. For applications that require a quicker engagement time or a lower operating temperature, you simply need a controller for the brake to accomplish this.

Brake Overexcitation

You can overexcite the brake to achieve a faster response and lower the voltage after disengagement (to a holding voltage typically 50% of rated) for an equally low running temperature as an AC brake. Since the coil is the most expensive component of a brake, you’d want to ensure it lasts the longest. Due to AC brakes having an in-rush current and the possibility of a large air gap, the coil will burn out more frequently. This will not happen to a DC brake that is applied to the correct voltage.

Another thing to consider besides the function of the brake is how it will be implemented into your machine or design. An AC brake may be easier to implement off-line voltage, but then you have to run higher voltage cables and at these voltages, achieving UL with the brake is more time-consuming.

DC brakes can simply use a KEB rectifier (ours are UL approved) and be implemented similarly to the AC brake. However, most drives and controllers have a 24VDC output which can conveniently be used and controlled for the brake.

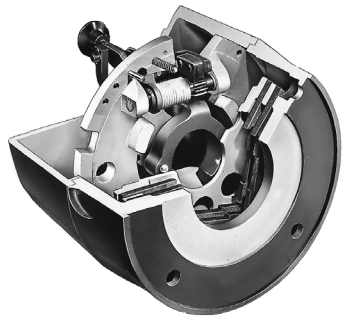

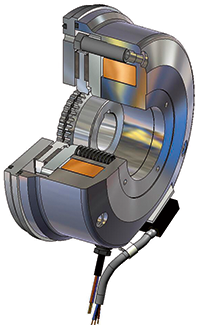

DC Brakes – Simple Construction

Finally, the construction of AC and DC brakes is different. AC brakes typically feature a solenoid plunger and linkage mechanism. This provides a number of different wear parts that can potentially fail over time with repetitive cycling. The beauty of the DC brake design is in its simplicity. There is only one moving part – the armature – and it does not have any pivot points. This design is particularly well suited for high cycling applications. When considering the total lifetime cost of the different brake technologies, DC-style brakes become very attractive.

DC Brakes from KEB America

For the reasons stated above, we believe that DC brakes are the way to design your system for. There are no major disadvantageous of DC brakes over AC brakes that can’t be alleviated through design.

Contact a KEB America engineer to discuss your braking application and we can provide the right-sized brake for you.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.