Replacing Clutch and Motor Brake Rectifiers with KEB Rectifiers

This post serves as a guide for crossing-over rectifiers commonly used with DC clutches and brakes.

There is a 6-step process outlined. Additionally, at the end of the article, there is a crossover chart with KEB rectifier part numbers.

Why replace a clutch or brake rectifier with a KEB rectifier?

1.The brake rectifier is a passive device and relatively easy to change out.

KEB carries COMBITRON rectifiers compatible with many electromagnetic DC brakes and clutches. Best of all, our brake rectifiers are simple to swap out with proper preparation. We’ll outline this process in detail below.

2. KEB rectifiers are industrial grade and of better quality than those supplied with most OEM products.

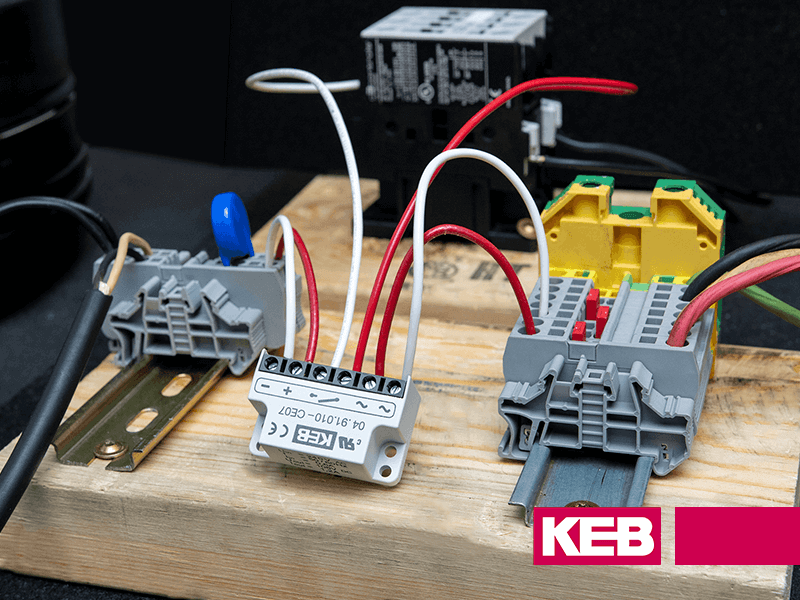

For example, our brake rectifiers feature a robust design to accommodate even the most demanding industrial applications. These solutions contain internal MOVs to protect against voltage peaks of switching contacts and allow for switching on either the AC or DC side to maximize response times.

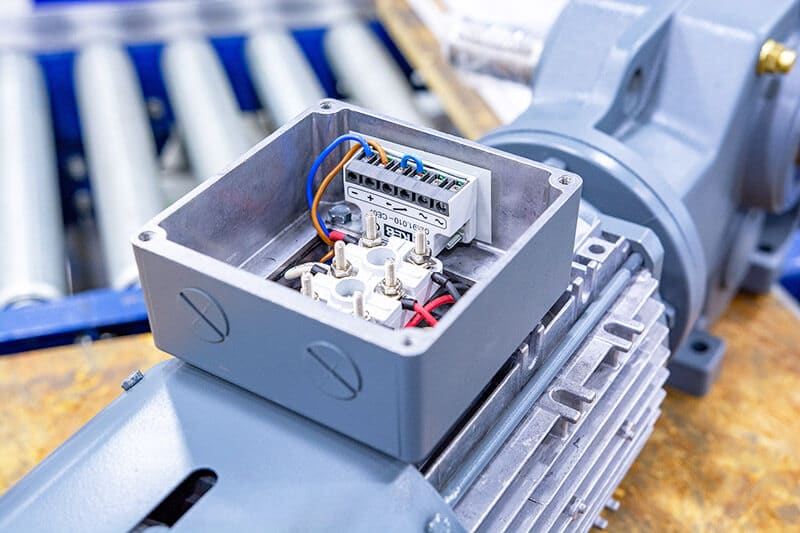

KEB rectifiers are very compact, often allowing them to be mounted directly in the motor terminal box. These solutions also offer DIN mount versions to simplify panel integration and a reduced holding voltage option to improve response times and limit power consumption.

3. KEB rectifiers are UL listed – #E308765.

Check your current rectifier product – most are not listed. All of our rectifiers have been tested by UL to nationally recognized sustainability and safety standards. This important seal of approval makes them an ideal solution for virtually all electromagnetic DC brakes and clutches, ensuring safety and longevity across applications.

4. KEB rectifiers are stocked and ready to ship.

As an industry leader in control and automation technology, KEB offers a full selection of half-wave and full-wave rectifiers – built for worldwide use and ready to ship anytime! Our production and supply capabilities ensure that we’ll have the rectifiers you need in stock and available exactly when you need them.

5. What type of rectifiers can KEB replace?

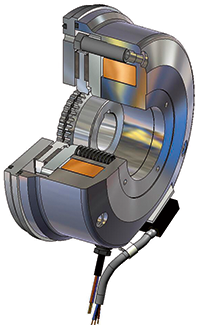

Any brake or clutch using a DC coil. Here are some examples:

- Gearmotor or motor brakes from suppliers like SEW Eurodrive, Nord, and Sumitomo

- Clutches from suppliers like Warner and Ogura.

- DC brakes from suppliers like Lenze, Intorq, Stearns, and Precima.

The 6-step process for crossing over clutch or brake rectifier

1. Download the KEB Rectifier manual

First, for reference, you’ll want to download the KEB rectifier manual which has all the dimensions and ratings.

2. Double-check that the brake or clutch has a DC coil

AC brakes use solenoids and do not need rectifiers. For more information, check out this post which compares DC vs. AC brakes.

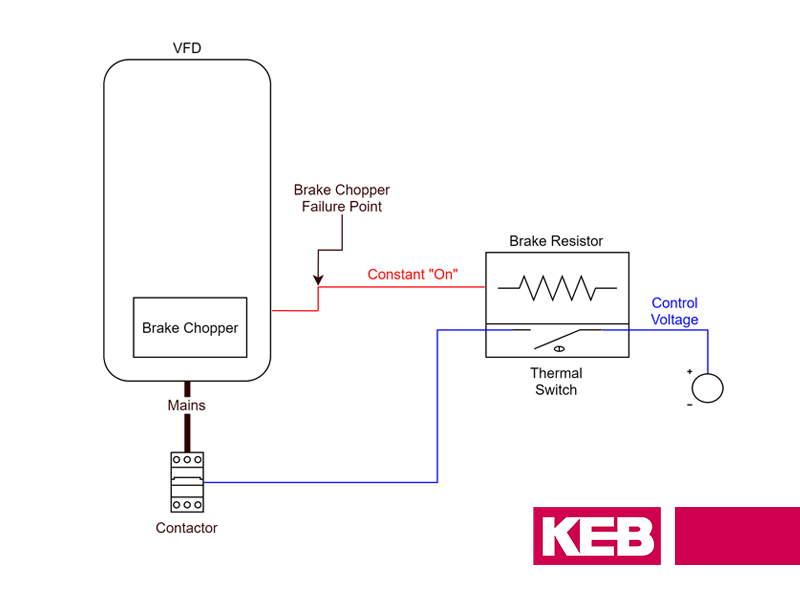

3. Verify if you need a half-wave or full-wave rectifier

Check the incoming AC voltage and your rated DC electromagnet voltage. Decide which type of rectifier will give you the correct output voltage.

Please note, this post only applies to standard half and full-wave rectifiers – not overexcitation types that have a time-based component. Also, 24VDC magnets do not need this type of rectifier and will typically be supplied from a 24V power supply.

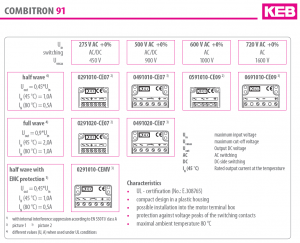

For reference, here is a grid showing the different KEB rectifiers by Type and Voltage rating:

4. Verify the rectifier voltage and current rating

The listed VACInput on the rectifier should be greater than the incoming AC voltage you are connecting. See pages 4 and 5 of the KEB rectifier manual for the max input voltage ratings.

The amp draw for the magnet can be calculated if the voltage and coil wattage is known.

Ensure the amp rating of the KEB rectifier exceeds the amp draw of the electromagnet coil. This is also listed on pages 4 and 5.

5. Verify how the current rectifier is being switched – AC or DC side switching

For more information on AC and DC side switching wiring, see page 6 of the KEB rectifier manual.

If DC side switching is used, select one of KEB’s switches rated for 500VAC or less. They will start with either a 02 or 04.

6. Verify physical dimensions

Finally, verify that the rectifier will fit in your terminal box or electrical cabinet. See page 5 of the KEB rectifier manual for dimensional info.

Crossover List

*Always double-check the compatibility of specs, including input voltage and rated current.

Intorq (Lenze)

- BEG-142-270 –> KEB 0291020-CE07

- BEG-143-270 –> KEB 0291020-CE07

- BEG-242-555 –> KEB 0591010-CE09

- BEG-243-555 –> KEB 0591010-CE09

- BEG-162-270 –> KEB 0291020-CE07

- BEG-161-270 –> KEB 0291020-CE07

- BEG-262-460 –> KEB 0491010-CE07

- BEG-261-460 –> KEB 0491010-CE07

Nissei / Oriental Motor / Brother

- A200-D90 –> 0291010-CE07

Nord

- GHE40L (Pn: 19141010) –> KEB 0491010-CE07

- GPU40L (Pn: 19140170) –> KEB 0491010-CE07

Reissmann

- 45 B 50 20 – C1V –> 0491020-CE07

- 45 B/E 50 12 -AUL5303V2 –> 9098200-001U

- 45 E 57 20-C1V –> 0591010-CE09

- A200-D90 –> 0291010-CE07

SEW-Eurodrive

- BG1.2 (Pn: 826 992 0) –> KEB 0591010-CE09

- BG1.4 (Pn: 827 881 4) –> KEB 0591010-CE09

- BG1.5 (Pn: 825 384 6) –> KEB 0591010-CE09

- BG2.4 (827 019 8) –> KEB 0291010-CE07

- BG3.0 (Pn: 825 386 2) –> KEB 0591010-CE09

Stearns

- 412-0291-01K –> KEB 0291020-CE07

- 412-0292-01K –> KEB 0291020-CE07

- 412-0591-03K –> KEB 0591010-CE09

Warner

- ACG830A1P1 –> KEB 0291010-CE07

- ACG830A1P2 –> 0291020-CE07

KEB America: Your Partner for Clutch and Motor Brake Applications

If you have questions about crossing over your rectifier, contact a KEB engineer today. Our team has decades of experience delivering innovative solutions for DC clutches and brakes, including industrial-quality rectifiers. We’ll work with you every step of the way to find the right product for your unique application.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.