Purpose Built for Commercial Vehicle and Mobile Machinery Applications: T6 Auxiliary Inverter

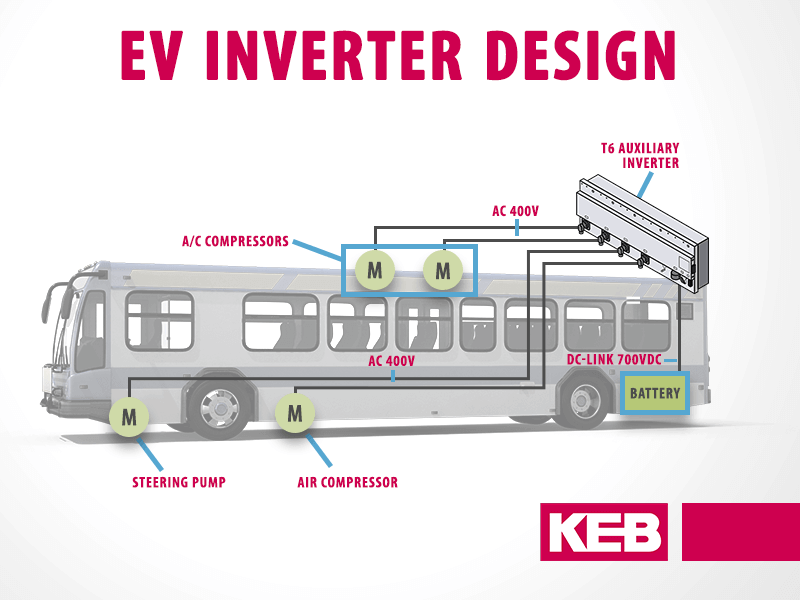

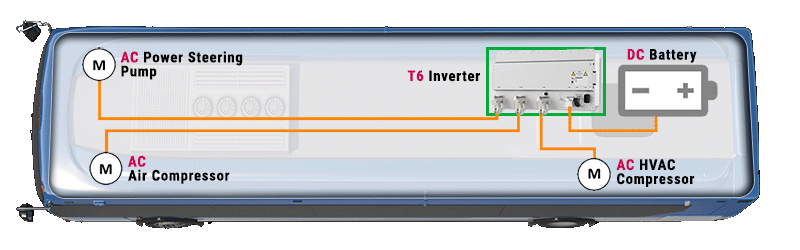

As the demand for electrified vehicles continues to grow in both on and off-highway applications, a greater number of powerful electronic components are being integrated into new vehicle designs. It is crucial for these components to comply to the stringent vehicle standards, as cutting corners can compromise reliability and longevity. Inverters have historically been rooted in industrial applications where they are installed in a stationary enclosure. On the other hand, automotive conditions are comparatively harsh and therefore require a rugged inverter designed, packaged, and tested to meet these requirements.

To ensure the highest level of quality and reliability, the T6 Auxiliary Inverter is purpose-built for automotive and mobile machinery applications. In addition to using automotive-grade components and processes, the T6 was designed to meet the stringent standards and operating conditions for these types of applications. Here, we’ll discuss design aspects and certifications that make the T6 so well-suited to meet these requirements.

Certifications – E1, CE Marks

Certification markings ensure products are safe and effective to use by meeting regulatory, technical, and safety requirements. Even more stringent are type approvals certified by third parties, which also grant certificates of conformity ensuring the ability to produce a series product with the necessary quality and process controls to maintain the certification requirements.

One of strictest class of products include EU regulations for passenger and on-highway vehicles, which require an E-mark type approval. Here, the T6 has received the E1 type approval marking for the intended use in highway vehicles with Conformity of Production certified by the German Federal Motor Transport Authority, KBA (Kraftfahrt-Bundesamt). And for other types of mobile applications, such as off-highway machinery or body equipment, the T6 is certified with a CE marking.

Although E- and CE-marks are not mandated in North America, meeting these certifications requirements can still serve as suitable proof of compliance in homologation processes which require meeting similar standards.

Learn more about the homologation here: What Does Homologation Mean And Why You Should Care

Electromagnetic Compatibility – ECE R10, (EMC) Directive 2014/30/EU

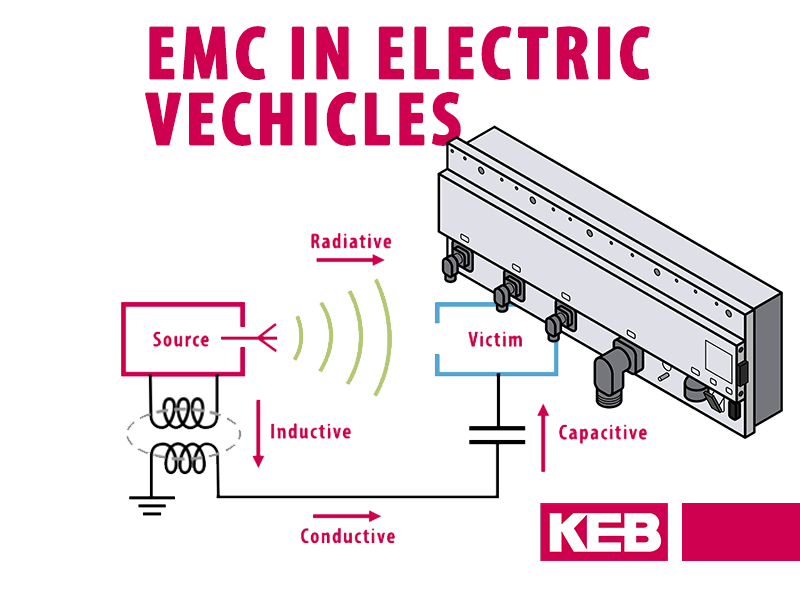

“EMC or Electromagnetic Compatibility means the device will work as intended without interfering with, or being affected by, the use or function of any other device.” [Wikipedia.org, CE marking]

Electromagnetic compatibility should always be a central concern in electric vehicle applications. With more electronic components being integrated into new vehicle designs, unchecked high-voltage power electronics can generate electromagnetic interference (EMI) which can disrupt the intricate electrical systems within the vehicle as well as potentially cause physical damage to other equipment.

Learn more about Electromagnetic Compatibility here: EMC Considerations for Auxiliary Inverters in Electric Vehicles Applications

To mitigate EMI, multiple EMC design elements were incorporated into the design of T6 and rigorously tested. These design features include integrated DC common mode filters to both prevent and protect against disturbances as well as connector and clamping designs optimized for shielding effectiveness. In addition to manufacturing inverters, KEB also designs various filter technologies and has the facilities and equipment in-house to perform rigorous EMC design testing.

A key component to the E- and CE-mark certification requirements for electronics subassemblies (ESA) in vehicles are the corresponding ECE R10 and (EMC) Directive 2014/30/EU) standards regarding EMC and immunity to radiated and conducted emissions. Therefore, these certifications also ensure the T6 is able to operate within a vehicle’s electromagnetic environment without interruptions and the further detailed attention to EMC design and testing also ensures the T6 will provide the highest level of operational reliability.

Mechanical and Thermal Conditions – ISO 16750

On and off-highway vehicles experience some of the harshest mechanical and thermal conditions of all electronic applications. Commercial vehicles must withstand rough and bumpy rides, with conditions ranging from the humid heat of Florida to the freezing winters of Minnesota.

In response to these challenges, the T6 employs a robust construction that meets the stringent requirements of commercial vehicles. Mechanically, it adheres to ISO 16750-3, Code L, guaranteeing resilience against heavy vibrations and shocks. Thermally, the T6 utilizes a liquid cooling system that enables it to withstand a wide range of climatic conditions, ranging from -30 to +70°C operational ambient temperature in accordance to ISO 16750-4, Code Z.

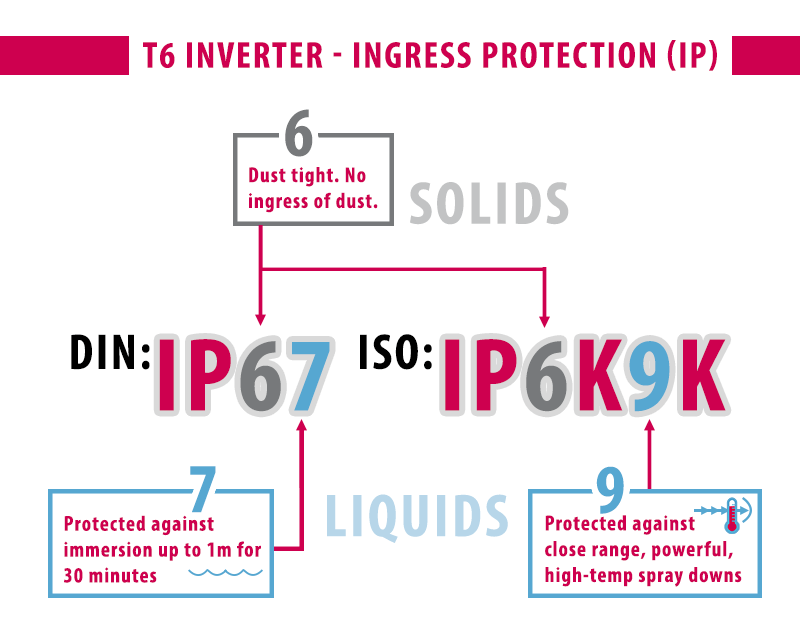

Protection Class – IP67 / IP6k9k

Commercial vehicles face exposure to harsh elements such as rain, debris, and even high-pressure cleaning. It is imperative that high-voltage power electronics are suitably protected against these elements, as ingress of particles and/or water into these systems has the potential to be catastrophic.

To this end, the T6 housing and connectors are rated to IP67 (DIN) and IP6K9K (ISO). This means that the T6 is completely shielded against dust, protected from contact, capable of withstanding temporary submersion, and resistant to high-pressure/steam cleaning. Not only does this make the T6 incredibly reliable in normal vehicle usage, but it also has the potential to be mounted externally.

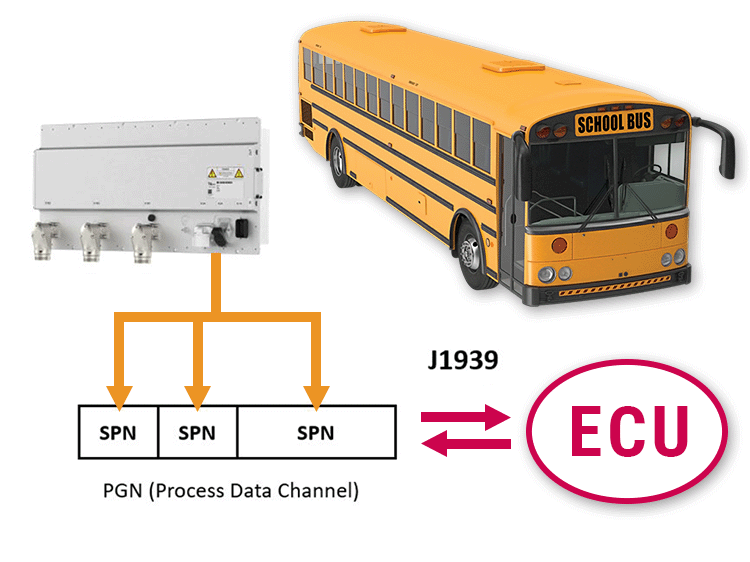

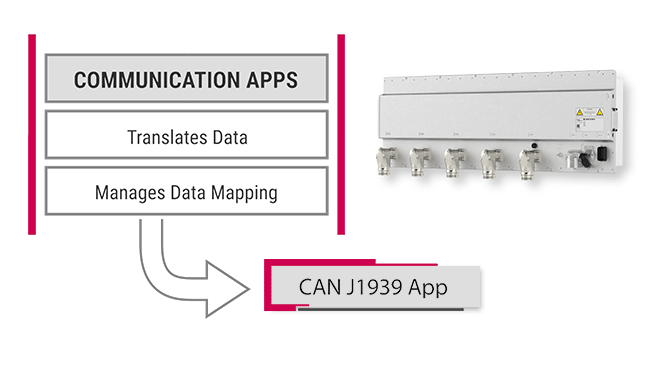

Communications – CAN J1939

Finally, the T6 Auxiliary Inverter supports CAN communications in accordance with the SAE J1939 protocol. CAN J1939 is the established standard for electronic communications in heavy-duty on/off-highway vehicles. J1939 compliance is crucial, particularly as electrified vehicles and equipment incorporate an increasing number of electronic control units (ECUs) to control advanced vehicle functions and features.

Learn more about T6 J1939 Communications: J1939 Process Data Gateway App for Electrified Auxiliaries

Conclusion

The T6 Auxiliary Inverter is a purpose-built solution designed to meet the stringent standards and requirements of automotive applications. This makes it a trusted choice for auxiliary electrification in commercial electric vehicles. To learn more about how the T6 can benefit your eMobility application, please contact a KEB Applications Engineer below.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.