KEB is somewhat unique among drive manufacturers because we offer an extensive selection of accompanying filters that are designed in-house. This includes harmonic filters for reducing current distortion to IEEE519 levels. We offer sinewave filters that can be used in high-speed applications or VFD applications with long cabling.

Most commonly, we are providing our low leakage EMI filters which help mitigate the effects of high-frequency electrical noise. They work so well some of our drive competitors even buy them.

This post outlines 5 reasons why you should consider using KEB’s E6 EMI Filter product to improve drive performance.

An EMI Filter Primer

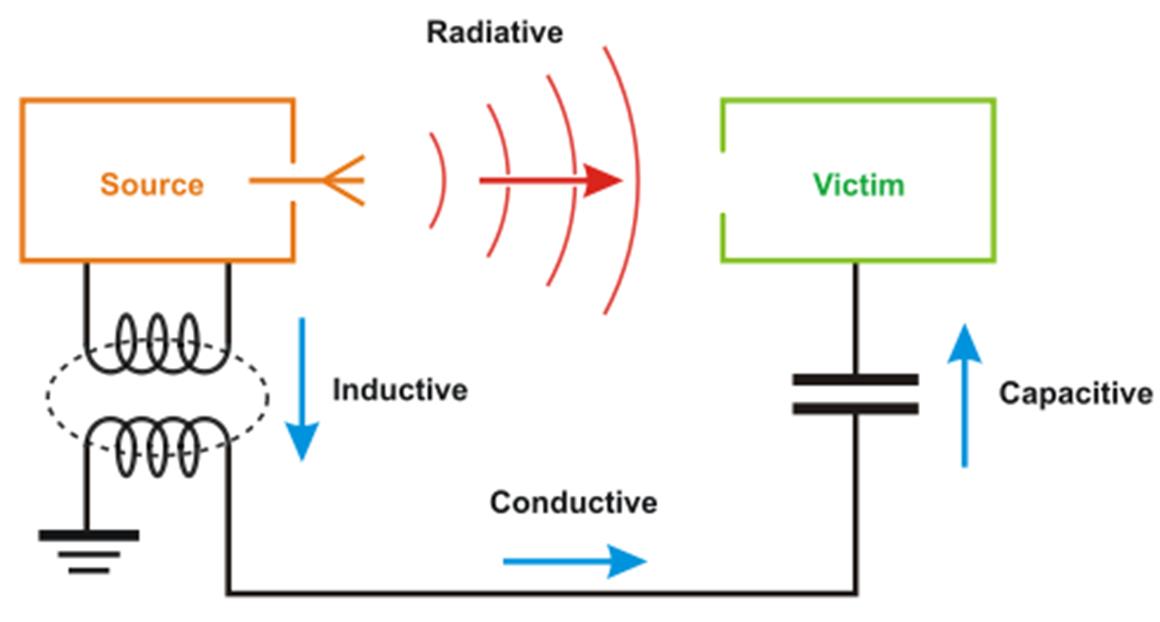

EMI filters mitigate the effects of electromagnetic interference. They are also sometimes called RFI (radio frequency interference) filters because they suppress noise up to 30MHz.

Sometimes, EMI Filters get confused with harmonic filters because they are both placed at the input of a VFD. However, they are engineered differently and solve different problems.

EMI filters target high-frequency electrical noise while harmonic filters address power harmonics at much lower frequencies (<400Hz).

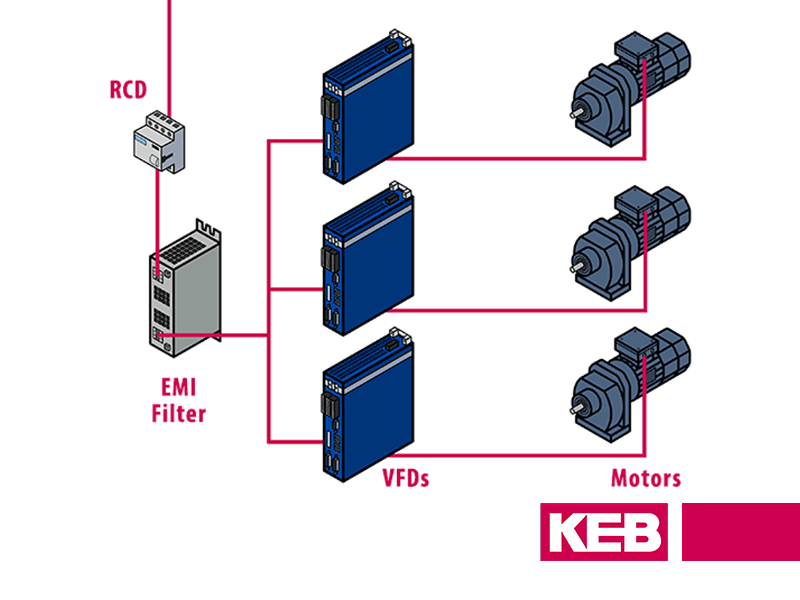

It is best practice to use EMI filters with your VFD. Applied correctly, an EMI filter will keep the drives emitted electrical noise from going back to the line and affecting other connected loads. Filters also protect the VFD from the noise that might be coming from other loads on the supply. So a good filter will protect both the VFD and other electrical loads.

Machine builders looking to sell in Europe and elsewhere need to comply with EC Directive 2004. This means using components that are CE labeled and meet the correct EMC requirements. For VFDs, this often means adding an EMI filter either internally or externally. Here in the states, EMI filtering is not required for VFDs. However, adding an EMI filter can reduce nuisance trips in the drive and make for a more robust electrical system so it is often worth the investment.

Now onto a few unique features with KEB’s drive offering.

1. Low Leakage Current – It’s the safe solution

A drive will have some leakage current to ground. Factors like the type of motor cables, length of motor cables, installation in cable trays or not, etc. will all contribute to the amount of leakage current.

Leakage current can be potentially dangerous in two ways. First, it can give a person an electric shock. This is particularly true in applications where a user is near or around water. This is difficult to avoid in some applications like food processing or packaging machinery. Second, leakage current can contribute to fires. Because of the dangers, RCDs are increasingly being specified and used in machinery. A residual current device (RCD) is like a GFCI circuit in a house. The circuit is monitoring the leakage current to ground. If the leakage current exceeds a prescribed value, then the RCD will trip and break the circuit – turning off the machine.

Traditional VFD EMI filters could have relatively high leakage current values, say 150mA or more. These older filters designs are often not compatible with the newer RCDs being used. Therefore, KEB has designed low leakage EMI filters that can have as much as 1/10th of the leakage current compared to previous designs. There are many factors at play (e.g. cable type and length), but typical leakage current values with the E6 filter line are going to be less than 5mA.

E6 filters are designed for low leakage current applications

Sometimes customers ask if they can use KEB filters with a different brand of drive. Here’s a dirty secret – The KEB filters are compatible with 3rd party VFDs. In fact, some of our drive competitors buy and use our E6 filters. The main reason is the high-performance filter achieved and the low leakage current.

2. High Performance

The 6 in E6 stands for 6th generation. It is an improvement on an already successful filter product that KEB has been using for 20 years. KEB EMI filters are designed to suppress electrical noise in the band from .15 to 30MHz.

The filters can be used to meet EMI requirements for both EN 61800-3 Class C1 and Class C2 environments. Meaning they are suitable for industrial and, even stricter, residential environments.

The E6 filters attenuate high-frequency electrical noise and meet requirements for use in Class C1 and C2 environmentsKEB RFI filters have CE and cUL approvals so a machine builder is covered for whatever region their machine might ship to.

3. Full-size range – up to 330 Amps

The E6 is suitable for small and large drive applications alike. The filters are offered in 8 graduated housings starting at 12 Amps and carrying up to 330 Amps.

The filters can be used with input voltages up to 550VAC and can be used with both 50/60Hz mains.

| KEB part no. | Rated current (A) | Leakage current (mA) |

|---|---|---|

| 12E6T60-3000 | 12 | <3 |

| 14E6T60-3000 | 22 | <3 |

| 16E6T60-3000 | 43 | <3 |

| 18E6T60-3000 | 65 | <3 |

| 20E6T60-3000 | 100 | <3 |

| 22E6T60-3000 | 150 | <3 |

| 24E6T60-3000 | 200 | <3 |

| 27E6T60-3000 | 330 | <3 |

4. Integrated Filters in KEB Drives – The compact solution

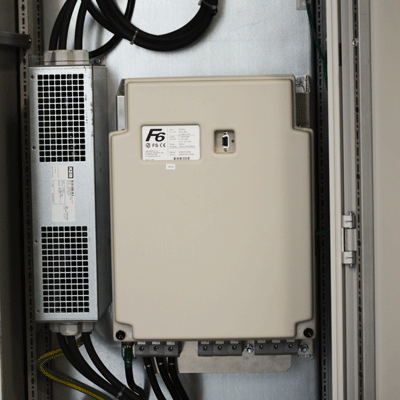

KEB has offered drives with back mount filters for a long time. This reduces panel space requirements and wiring time. KEB’s S6 servo drive is offered with and without an integrated EMI filter.

The S6 Servo Drive includes the E6 low leakage filter technology inside, allowing for a very compact drive package.

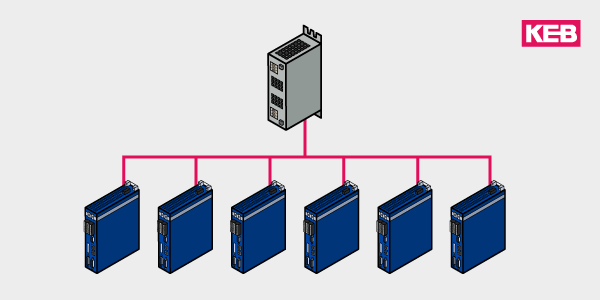

5. Can be implemented as a central filter for multi-axis applications

In multi-axis applications, the E6 EMI filters can be used as a central filter for all connected drives. The main advantage of this implementation is lower system costs and reduced panel space requirements.

A central E6 filter can feed multiple drive units in multi-axis applications. Instead of having 20 or 30 separate filters, one large central filter can be used for the complete system.

Are you having EMI noise problems in your application or nuisance trips? Speak with a KEB engineer today.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.