While EtherCAT technology optimizes control for your automated machines, Functional Safety over EtherCAT (FSoE) embeds safety functions within the communication relays of EtherCAT to increase flexibility and improve response times.

KEB offers Functional Safety products, so let us inform you everything about FSoE and why it is important to machine builders.

What is Functional Safety over EtherCAT?

FSoE is a communication protocol that combines control and safety functions to ensure your data gets where it needs to go while protecting your systems. It simplifies safety applications by differentiating between regular data and safety-critical data.

Functional Safety over EtherCAT protocol shortens the time between sending an emergency stop command and the affected part of the machine receiving and processing the message. Shorter reaction times mean your device is better connected and ready to work for you.

The EtherCAT Technology Group designed FSoE as an industrial communication bus that would be suited for use in safety applications – up to an IEC 61508 SIL3 level.

How Does FSoE Protocol Work?

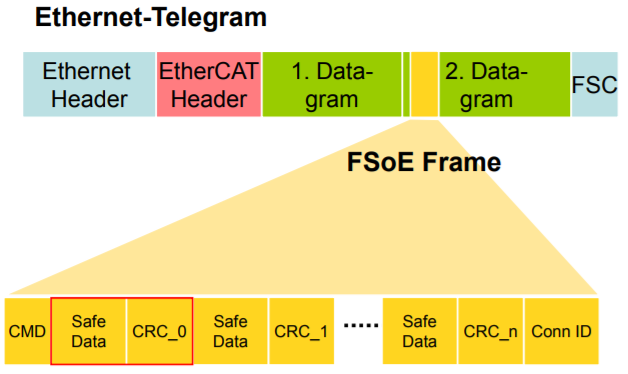

Each FSoE node receives a unique address (16-bit). The EtherCAT telegram encapsulates the safe data with checksum:

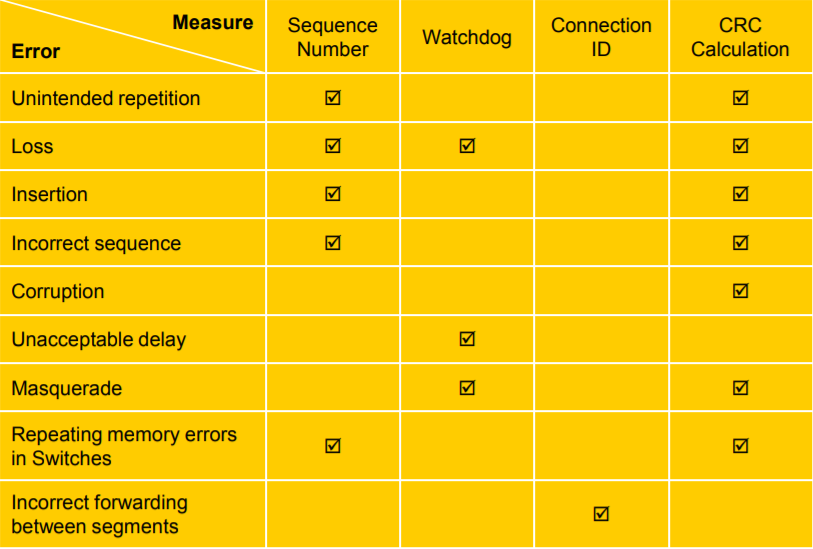

Overall, the Failsafe over EtherCAT protocol has several different features that help detect an error in communication, including:

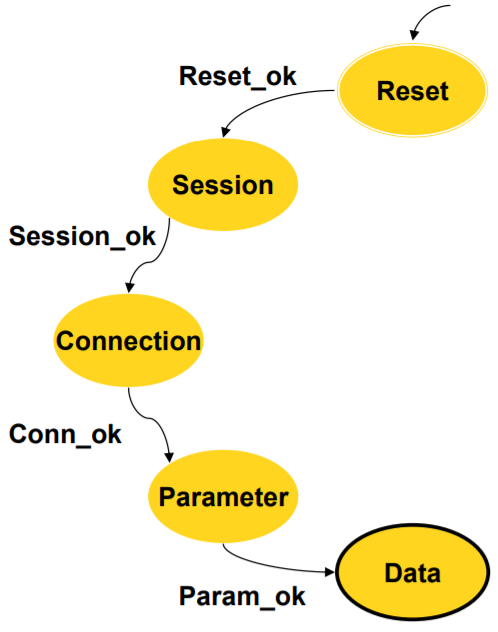

The FSoE master box regulates all the other system features and relays, known as slaves and state machines. In the event of an error, the state machine resets, and the master must revalidate the connection before changing any of the safe bits.

If you want more technical information, members of the EtherCAT Technology Group can download a full copy of the specification.

5 Reasons Why Machine Builders Care About FSoE

1. FSoE is certified to an IEC 61508 SIL3 level

FSoE was designed with many different features that enhance security and allow the detection of errors. The protocol includes watchdog timers that work with the master frame and checksums to ensure an optimal safety connection and error-proof monitoring across each FSoE frame transmission.

TÜV Süd Rail GmbH independently certified the FSoE protocol to the IEC61508 SIL3 level. It also meets new normative requirements. TÜV Süd Rail GmbH is an independent body specializing in defining and advancing compliance for safety, security, and sustainability solutions.

Since a third-party safety agency evaluates FSoE, when coupled with similarly certified safety hardware, the machine builder will have a much easier time getting their machine certified for functional safety.

2. FSoE is an Open Protocol

EtherCAT Technology Group (ETG) hit a home run with EtherCAT. It encouraged vendors to develop EtherCAT products by making the technology open and accessible.

Machine builders and engineers benefited because they could access many different vendors and products. Due to a competitive market, the end-user benefitted from high-performance technology and lower costs.

ETG also publishes FSoE. Increasingly, more automation companies will develop FSoE-based products, and availability will continue to grow. Machine builders and end-users will benefit from a wide selection of products and vendors.

This is not always true with competing safety protocols in today’s market. You don’t want to be stuck with one vendor’s hardware and programming because of proprietary technology.

Because Safety over EtherCAT is open, it gives machine builders options and lowers their risk by expanding the market and their resources.

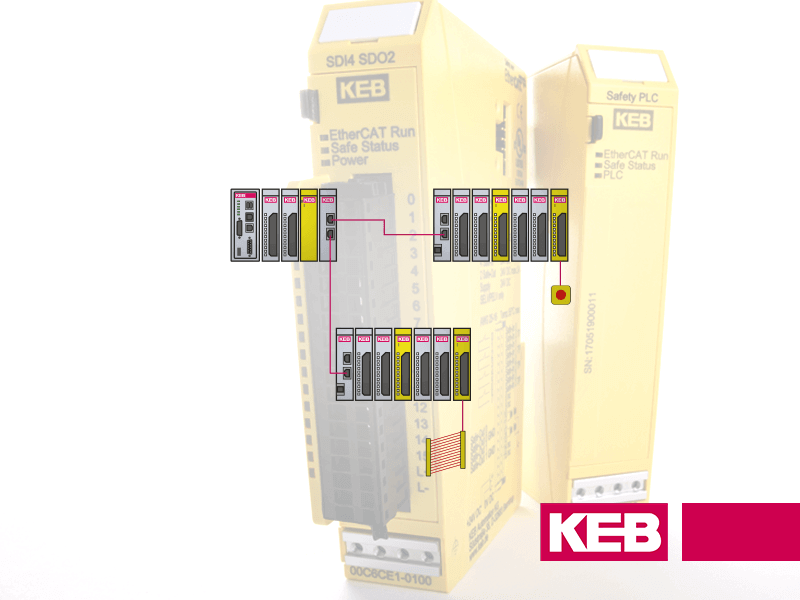

3. FSoE Works with Other Networks

FSoE works with standard ethernet hardware and network cables so that builders can use other programmable logic controllers (PLC) vendors and other industrial protocols. The FSoE safety network could even work with a mix of different control types, like on a large packaging line.

This unique feature gives a machine builder greater flexibility and advantage, considering the huge time and cost required to certify the functional safety of a machine. FSoE grants the machine builder a new depth of control and efficiency when building and configuring solutions across networks.

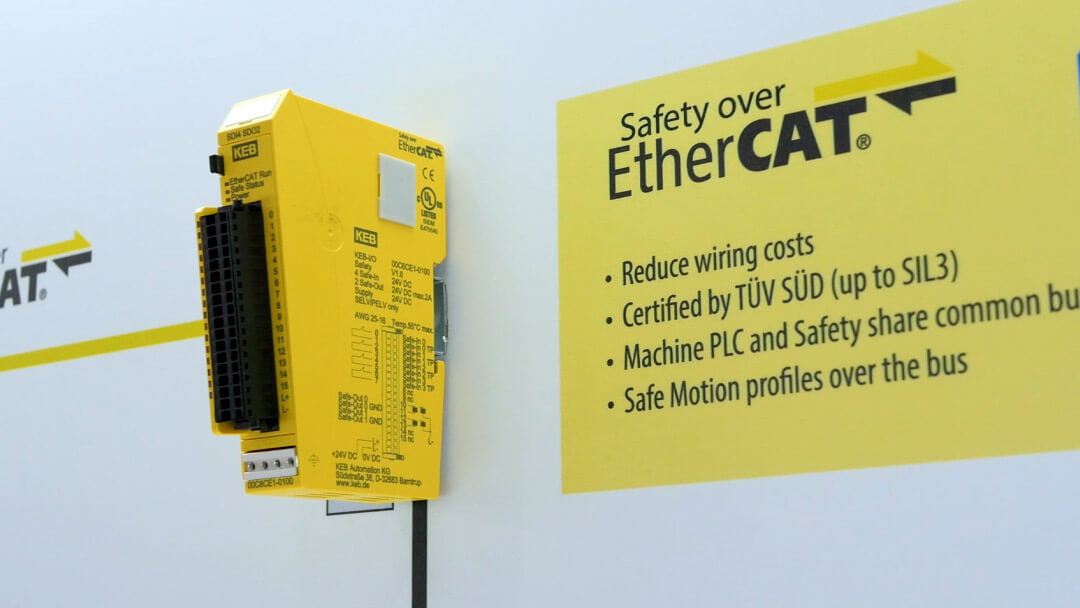

4. Safety over EtherCAT Saves Wiring Costs and Time

Another advantage of FSoE is you can replace much of the discrete safety wiring with a network cable. Manufacturers of rental and mobile machinery will benefit significantly from this. The design of the safety system is primarily done in the software and by using certified FSoE hardware.

There are many advantages to replacing conventional discrete wiring with network cabling, including:

- Reduction in wiring time – replacing safety wiring with a network cable allows machine builders to arrange and distribute electrical wiring more quickly, supporting faster and more efficient production.

- Reduced wiring errors – FSoE network cables are a safe and simple alternative to discrete wiring. These solutions remove many complications and the potential for wiring errors across machine construction.

- Clearer panel layout – Thanks to their efficient design, network cables support cleaner panel layout and wiring – allowing machine builders to produce logically arranged and easy-to-maintain control panels.

- Better noise immunity – FSoE network cabling drastically improves a machine’s ability to operate in the presence of noise disturbance and maintain fast, error-free connections over continued use.

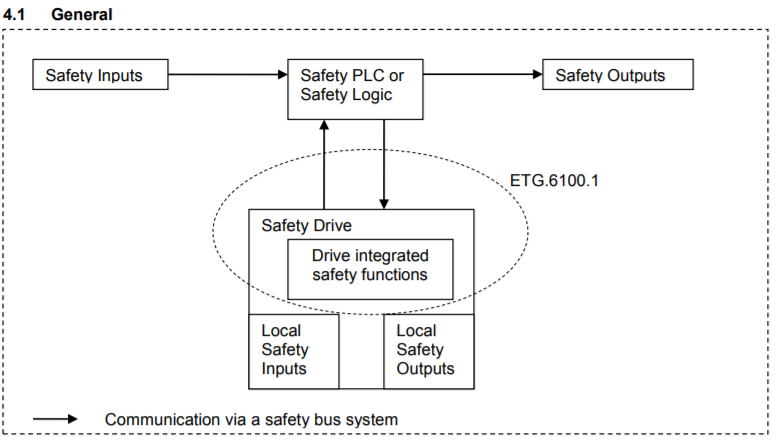

5. FSoE Allows for Functional Safety in the Drive

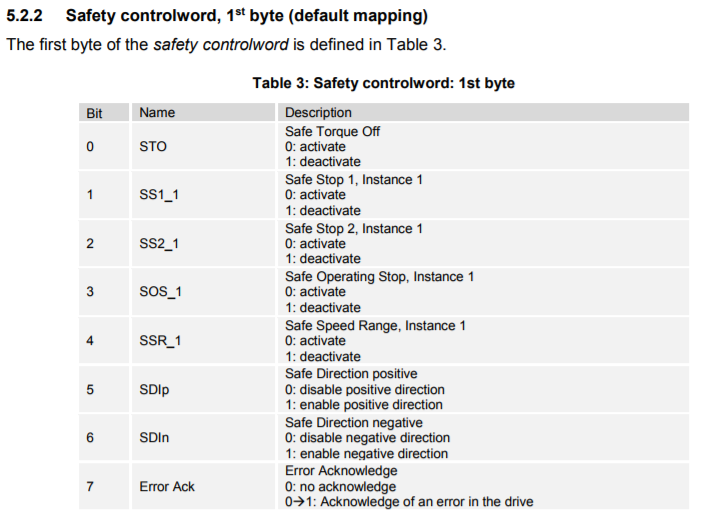

By design, the FSoE control word allows for advanced Safe Motion functions. This means it’s possible for an FSoE slave box, like an inverter, to handle advanced safety functionality like Safe Limited Speed or Safe Limited Positioning.

By default, the drive’s safety control word configures functions. Additional safe functions are possible with manufacturer-specific bits.

Inputs can locally trigger the safety function in the FSoE drive, or the FSoE bus can enable it. The FSoE master can also communicate the status back with the drive’s Safe status word.

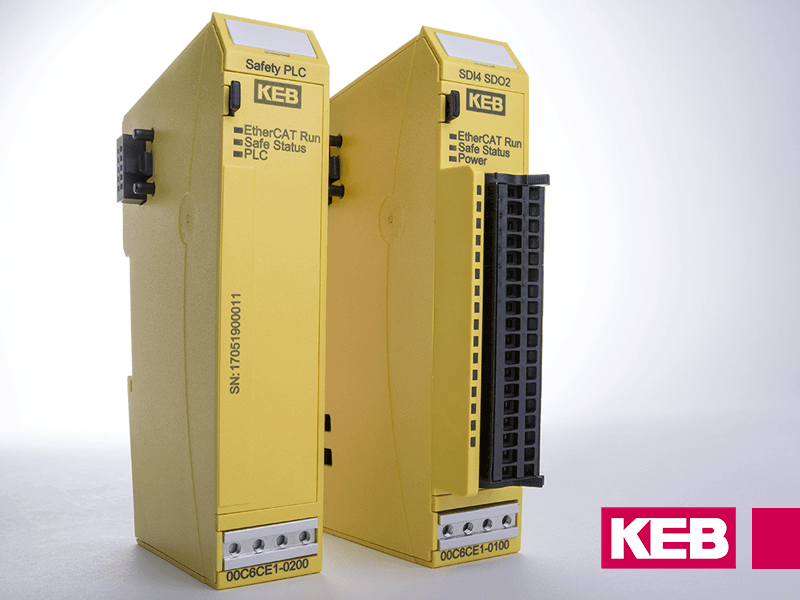

KEB EtherCAT Drives and Functional Safety Solutions

All KEB 6th-generation drives offer FSoE as an optional feature. Our EtherCAT drives allow machine builders to cost-effectively support safety functions while enabling peerless motor control for almost any motion control application. KEB drives are compatible with various motor types, ranging from induction and AC servo motors to linear and synchronous reluctance motors.

Talk to a KEB engineer to learn more about the advantages and disadvantages of Failsafe over EtherCAT for machine builders. Our team can help you find functional safety products for your unique project.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.