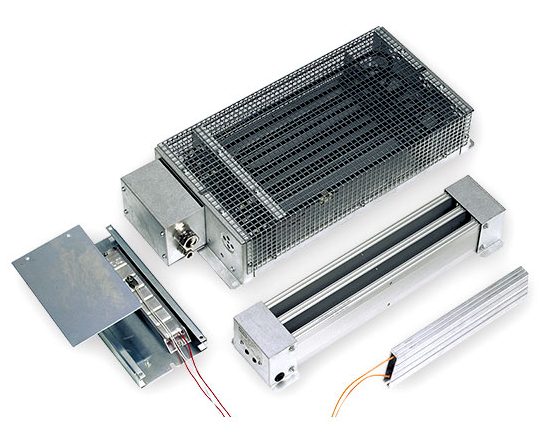

Braking resistors are used to dissipate excess energy in overhauling VFD applications. KEB high-performance resistors are offered in a variety of sizes and configurations along with intrinsically safe types.

Braking Resistors

Product Details

KEB offers several different types of braking resistors in both 230V and 460V classes.

Various design types include backmount, encapsulated, and wirewound brake resistors.

KEB dynamic braking resistors are UL recognized, certifying its design quality.

KEB offers a line of intrinsically safe brake resistors for added protection. The resistors are designed to fail in a safe way instead of catching on fire. These resistors are UL-recognized.

KEB offers drives with back-mounted brake resistors. Panel space is always a premium, allowing for a very compact and small drive footprint.

Tech Specs

Electrical

• Voltage Class – 230 and 400V

• Up to 26kW continuous (440kW 6 second duty)

• Intrinsically Safe – Optional

Mechanical

• Type: Encapsulated and Wire wound

• Protection: IP20 standard (IP60 optional)

Certifications

• CE and UL recognized

Options

Option: Intrinsically Safe Resistors

What are Braking Resistors?

What is it?

Braking resistors are used in VFDs to dissipate unneeded energy produced in the motor, allowing the drive to safely and effectively brake the load. Braking resistors are often the most simple, cost-effective solution in applications requiring fast deceleration.

Braking resistors are essential in operations where the speed of the motor surpasses the speed set by the VFD. These tools support superior braking torque capacity, while keeping bus voltage within the drive’s rated limit. This produces more responsive and reliable braking for even the most demanding industrial applications, preventing overvoltage and damage to the drive.

How Do Braking Resistors Work?

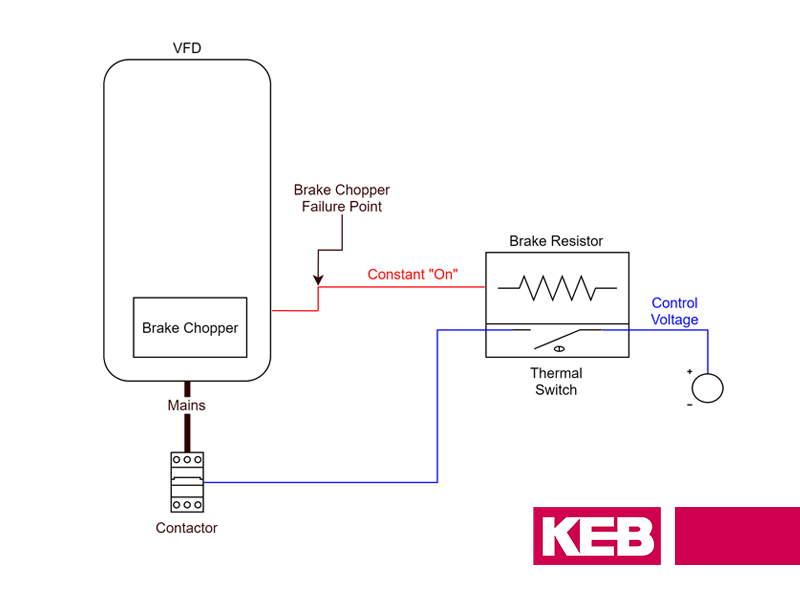

When there is an overhauling load and a drive is used to decelerate the motor, this can create excessive DC bus voltage. If this voltage is not properly controlled and dissipated, it can lead to voltage faults in the drive. Braking resistors for VFD applications can dissipate this excess energy by transforming it into heat over a resistor element.

Correctly sizing a braking resistor is crucial for safe and effective use. Braking resistors for VFD applications require a minimum power rating to stay within acceptable temperature limits during braking operations. Working environment is a vital factor as well, especially in locations with flammable materials (such as sawdust).

Proper installation and testing are important to ensure the braking resistor meets UL standards and to limit the possibility of short-circuit failure. This is why KEB offers intrinsically safe brake resistors, which fail in a safe way to protect the system and avoid costly fires in the event of a short-circuit failure.

Braking Resistors for Industrial Applications

The benefits of braking resistors for VFD systems include safety, efficiency, and dependable performance. Braking resistors provide more precise, controlled braking to prevent hardware damage and nuisance faults in the VFD. These solutions bring several advantages over traditional friction braking, including faster motor braking, reduced component wear, and lower risk of mechanical braking failure. Common applications for braking resistors include elevators, cranes, lifts, and even wind turbines.

For elevator applications, a braking resistor takes on the entire load current, dissipating this power as heat to effectively decelerate the elevator. Speed control is also key for material handling applications, which use braking resistors to ensure smooth operation of cranes and other load-bearing equipment. In the context of wind power, braking resistors for VFD systems absorb excess voltage created by wind turbine motors, creating a braking effect while protecting the electrical drive system by converting this surplus energy into heat.

KEB provides a variety of additional features to support your unique industrial application, including drives with back-mounted brake resistors to minimize drive footprint. We also offer encapsulated and wire-wound braking resistors, which are UL recognized and support system performance through safe, efficient braking. Our team can help you select the ideal braking solution for your application needs and goals.

Lets Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

Let's Talk

KEB has helped our customers solve many automation challenges. Let’s discuss your challenges and goals and see how we can help.