There can be many challenges when it comes to selecting the right gearmotor for your theatre machine like space constraints, demanding limited duty operation, and low audible noise requirements. In addition to high-performance spring-set brakes, KEB’s gearmotor product is ideal for the theatre and stage industry. Here are some options to consider when selecting a gearmotor for your application.

Integral design

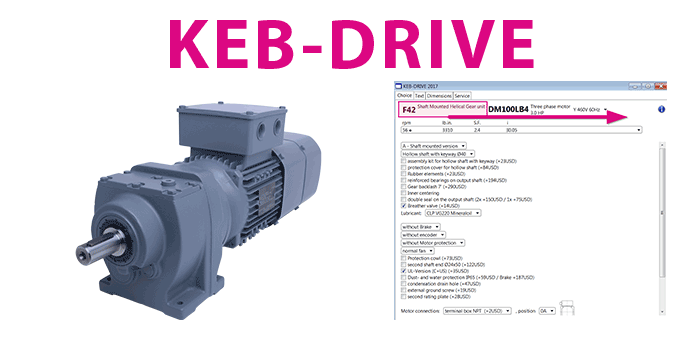

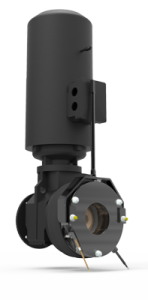

One benefit of selecting an integral gearmotor rather than a standalone motor and gearbox comes in the form of a more compact package. An integral gearmotor places the high speed pinion gear directly on the motor shaft so no intermediate adapter flange or coupler is required.

This typically results in a smaller package and makes the installation and maintenance easier as there are fewer parts for the machine builder to assemble. However, this does not mean a user is limited when it comes to the configuration of the gear arrangement. KEB gearmotors are offered in helical bevel, helical worm, inline, and parallel offset configurations to optimally fit in a variety of spaces.

These options allow the motor and hoist drum to be mounted inline, offset, or at a right angle to each other.

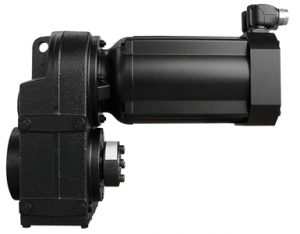

Because they are more compact with fewer parts, integral gearmotors will also typically be more lightweight than a separate motor and gearbox. This can be helpful when mounting multiple machines above the stage to an existing support structure. Lightweight is also beneficial when the machinery must be frequently set up and torn down for touring or traveling productions.

Motor types

Depending on the application requirements, either KEB AC induction or servo motors can be used. For the majority of applications an induction motor is often recommended because of it’s durability and economy. However, when space is a concern, or when higher performance or speed is needed, a servo (or synchronous) motor may prove to be beneficial. Either type of motor can be used in a KEB integral gearmotor.

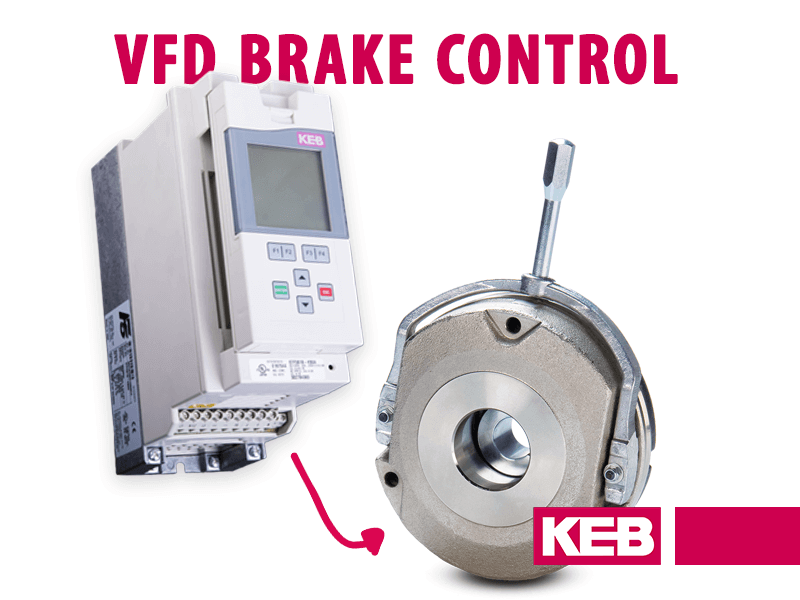

Spring Applied Brakes

One reason KEB gearmotors are ideal for theater hoists is because of our strong theatre brake offering which can be paired with the motors. KEB gearmotors feature DC spring-set brakes that use a redundant spring design to provide power-off failsafe braking. When safety is a concern spring-set brakes will be a better option over permanent magnet brakes which can fail open if the airgap becomes too large. For this reason DC spring-set brakes are KEB’s standard offering with all theatre gearmotors.

Gearmotor brakes from KEB have a variety of options available to suit the individual application. Brakes can be configured for different worldwide voltages and offered with manual hand releases. We also offer double brake options which have redundant electrical and magnetic circuits. Holding brake options have a boosted coil with more springs which allows higher brake torque with the capability to e-stop. A microswitch can also be added to the brakes in order to provide brake state feedback to the hoist control or VFD.

An important consideration in theatre applications is the amount of noise the machinery produces. KEB’s noise-reduced brakes were designed with theatre applications in mind and are virtually silent. As standard, KEB theatre brakes are designed to produce less than 65dB noise measured at a distance of 1 meter. In practice, our stage brakes are even quieter – even with the larger sizes.

Additional components

KEB’s standard gearmotor design can accommodate a wide range of additional components. Several different flange options are available. For example, KEB offers a gearmotor output flange that mounts directly to a KEB load brake – providing a compact assembly for a winch or hoist.

KEB gearmotors are also flexible when it comes to feedback devices. TTL or HTL incremental encoders are standard. Absolute encoder formats like BiSS or Hiperface are also possible. We can also incorporate a motor stub shaft which allows for a manual crank or handwheel. A forced ventilation fan can also be offered for applications requiring sustained operation holding full rated load at 0 speed.

Loads of options

There are many other options available for KEB theater gearmotors:

-

- Fanless – Given the limited duty of some theatre applications, there are options to ship without a fan to further reduce the noise created by the motor and shorten the overall gearmotor length.

-

- Power Quick-connect – if your theatre winch needs to be mobile we offer the quick-connect option that will allow you to easily move and re-connect the motor to the power supply.

- Customized brakes – if your setup has special braking requirements we c an offer custom solutions that fit your applications.

For more information on KEB America’s gearmotors and our capabilities:

You can also contact a member of our team for more information. Stay tuned for our next article in this series on theatre applications – Variable Frequency Drives.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.