Type 38 and Intorq BFK 457/458 – how do they compare?

There are a multitude of reasons to switch from a Lenze Intorq BFK457 and BFK458 to a KEB Type 38 Brake. KEB can offer quick delivery and service with local production and stocked parts located in the central US.

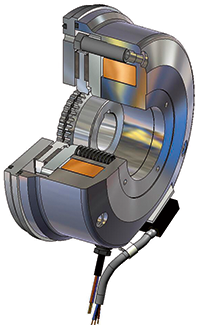

KEB also offers many variations of the brake including a high torque option that uses a high energy friction lining and has a wider range of torque ratings than the Intorq BFK458. The Type 38 is able to be used in static operation with the Combistop H, and dynamic operation with possible high speeds with the Combistop N.

Similarities make changing easy

There are some similarities between the Intorq and the KEB brake product. Both brakes use a 3 point bolt pattern with similar diameters that are specified in the KEB manual. Hub lengths are comparable among similar-sized brakes and can be swapped out as one of the many variations of the KEB type 38 brake.Comparing bolt patterns of the KEB Type 38 versus the Intorq BFK series most of the bolt pattern radii are the exact same. These attributes make the switch from Intorq to KEB pretty straightforward.

Process for crossing over a brake

1) Download the KEB brake manual Download the manual for reference of dimensions and ratings. Also gather the appropriate manuals and nameplate information from the brake you plan to cross over.

2) Check the torque needed Make sure you know what torque is needed, and match the torque necessary on the manual.

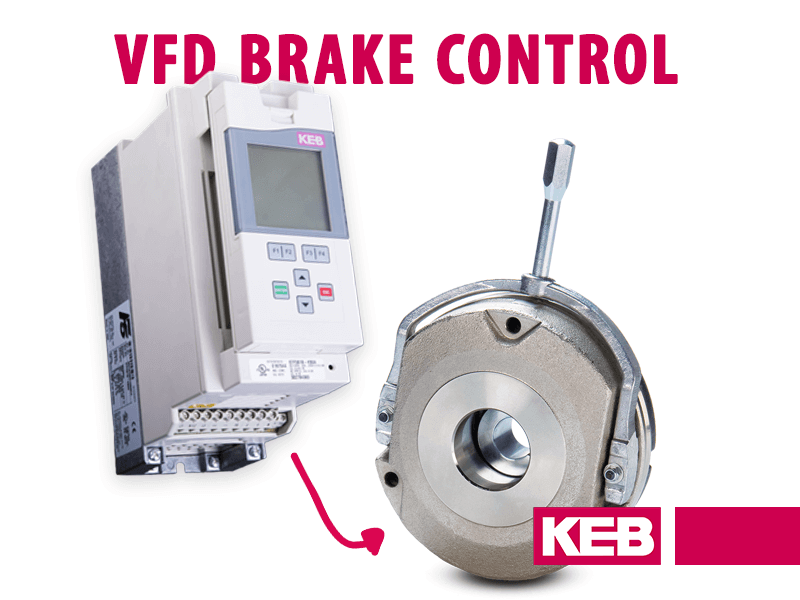

KEB “Version N” brakes are intended to be used in applications where the brake is being used to dynamically stop repetitively. “Version H” brakes are used for holding applications with the capability to provide e-stops.

| Type 38 Size | Version N | Version H | ||

|---|---|---|---|---|

| Rated torque (Nm) | Power input (W) | Rated torque (Nm) | Power input (W) | |

| 02 | 5 | 25 | 7.5 | 25 |

| 03 | 10 | 30 | 15 | 30 |

| 04 | 20 | 30 | 30 | 30 |

| 05 | 36 | 48 | 50 | 48 |

| 06 | 70 | 62 | 90 | 75 |

| 07 | 100 | 65 | 150 | 90 |

| 08 | 150 | 75 | 225 | 90 |

| 09 | 250 | 80 | 375 | 115 |

| 10 | 500 | 130 | 750 | 180 |

| 11 | 1000 | 180 | 1500 | 280 |

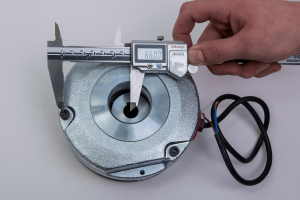

3) Verify the size of the hub needed Be sure to measure the size of the shaft and type of keyway in order to match the necessary hub. The customer should also verify the size of the radius of the brake they have. Note whether the dimensions are english or metric.

If the hub bore is special – like a spline – you will need to contact KEB for assistance.

4) Verify if the shaft has a key or not If the shaft has a key in it, be sure hub has a keyway cut.

5) Verify that the friction surface will suffice If the provided mounting surface does not work to produce correct friction, a suitable friction surface will need to be installed. KEB offers a secondary friction plate for this purpose, or the integrator can choose to add a KEB flange.

Before installing the failsafe brake KEB COMBISTOP observe the following:

1) Provide a suitable 2nd friction surface. Plane friction surfaces made out of suitable cast iron or steel. The surface roughness RZ should not exceed 25 µm. Avoid sharp-edged interruptions in the friction surface. If such a surface is not available a friction disc or flange can be used optionally.

2) The excentricity of the mounting hole circle to the shaft end shall not exceed following values: Size 02: 0,2mm; Size 03…06: 0.4mm; Size 07…10: 0.5mm.

3) The angular deviation of the mounting surface to the shaft shall not exceed following values: Size 02…03: 0.04 mm; Size 04…05: 0.05 mm; Size 06…07: 0.06 mm; Size 08…10: 0.08 mm (in reference to the bolt diameter).

4) The friction surfaces must be free from grease and oil.

5) Humidity, aggressive fumes and similar things can cause the rusting in of the friction lining. In such cases rustproof friction discs are optionally available.

6) The movement of the armature shall not be obstructed by objects substances that penetrate into the nominal air gap. If necessary,the protective rings (optionally) are to be used or other protective measures are to be taken.

6) Verify physical dimensions of the current brake Be sure that the physical dimensions of the brake selected based on the torque and shaft size fits inside the physical space provided. Be sure the bolt pattern fits with the current bolt pattern, or drill new holes for the bolts.

Click here to download the dimensions table for the Type 38 brake.

7) Verify the extra options desired on the brake Determine what options are wanted on the application. Available options include hand release, microswitch, dust protection ring, and a variety of flanges.

KEB – Your North American source for Spring-set Brakes

If you have any questions about crossing over your brake, feel free to contact a KEB engineer today or fill out the form below.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.