IP65-rated Servo Motors: Applications & Limitations

IP65-rated servo motors excel in many industrial applications, providing robust protection from solid and liquid contaminants. These compact motors make machines easier to clean, maintain, and safeguard from environmental threats like dust and oils. When searching for an ideal servo motor for your application, you may wonder whether this IP rating is sufficient or required. To answer that question, let’s discuss IP65-rated servo motors in depth—including a few of their key applications and limitations.

What are IP Ratings?

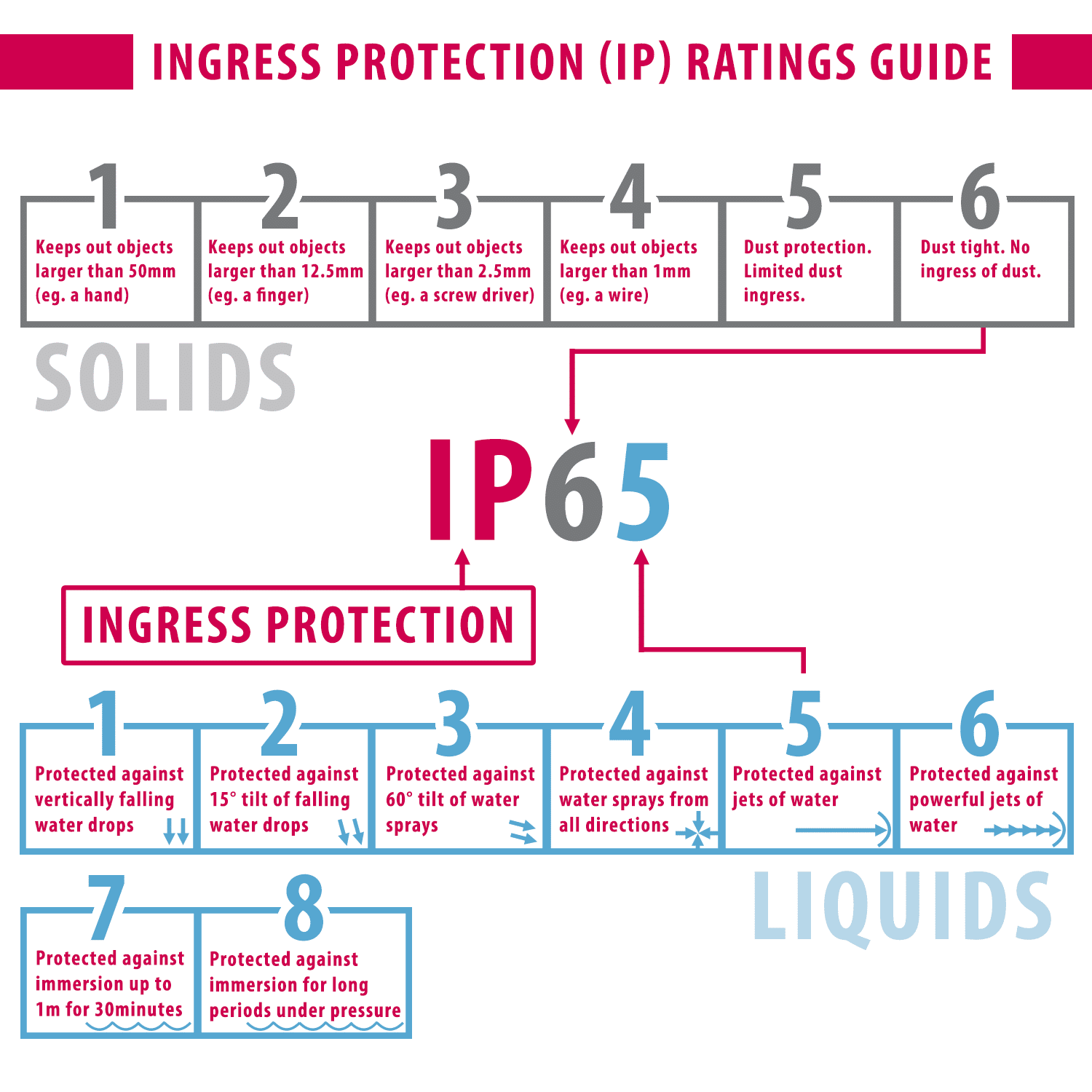

IP (or Ingress Protection) ratings tell us how well an electrical enclosure is protected against the entry of liquid or solid contaminants, including water, oil, coolant, or dust. This rating system was originally established by the International Electrotechnical Commission (IEC) and helps manufacturers of motion control products develop the right specifications for each solution.

A servo motor’s IP rating tells you how well-suited it is for operation across different production and work environments. Choosing a motor with a suitable rating helps maximize its reliability, performance, and overall operating life, while reducing risk and ensuring the safety of those using and maintaining the motor.

Defining the IP65 Rating

IP ratings contain a sequence of two to three numbers, each of which denotes protection from a certain contaminant type. The first number in the IP rating sequence indicates protection from solids, the second from liquids, and the third from mechanical impact when applicable.

Servo motors with the IP65 rating offer a high level of protection from solids (denoted by the 6). This effectively makes them dust tight and resistant to accidental contact and dust. IP65-rated components also have some liquid protection (indicated by the 5). Specifically, they’re protected from water projected by a nozzle (6.3 mm) against enclosure from any direction.

Applications for IP65-rated Servo Motors

Many industries leverage IP65-rated servo motors to optimize machine operations, improve safety, and make equipment last longer, including the following:

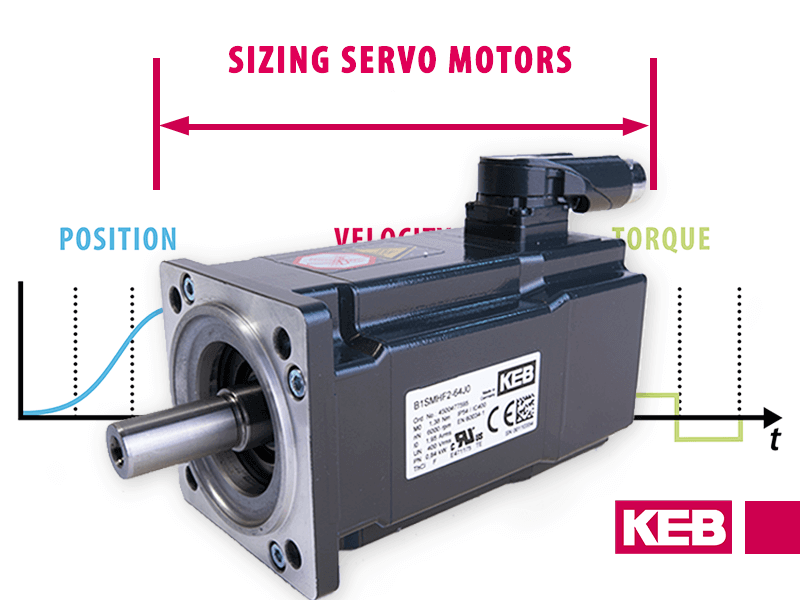

Packaging

Servo motors are a good fit for packaging applications because they enable highly efficient, precise operation to increase throughput. IP65 protection allows these servo motors to reliably support packaging systems transporting various liquid and solid materials. Proper servo motor sizing also allows packaging machine builders to create a smaller device footprint while maximizing torque-to-volume ratio.

Food & Beverage

Food and beverage processing exposes machines to various contaminants, including moisture and chemicals. IP65-rated servo motors can withstand these harsh environments with the help of additional protection features. For example, KEB servo motors include a unique epoxy coating option and shaft seal, allowing them to resist exposure to washdown procedures and caustic solutions used for food and beverage.

Medical/Life Science

Some medical applications require devices to pump and dispense various medicines or fluids, which necessitates robust liquid protection. Servo motors deliver a specified torque for tools like medical pumps, creating a compact, quiet, and dependable solution. These advantages make servo motor technology an attractive option for medical and life science devices, especially portable pumping equipment.

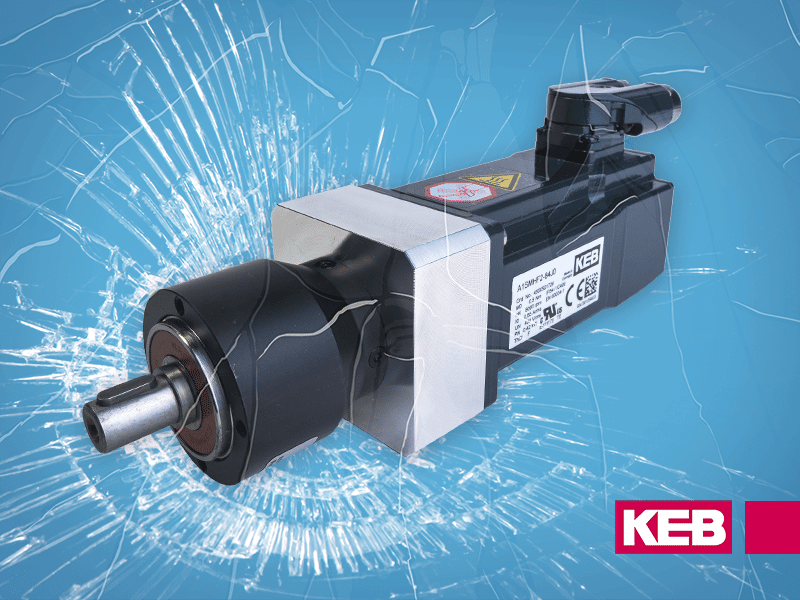

Metalworking

No matter how well maintained, production floors are exposed to many contaminants, from oil and coolant to lubricant and water. Metalworking machinery needs flexible control technology to survive these challenging working environments. KEB offers low and medium inertia servo motors for safe, precise motion control across metalworking applications—including IP65-rated models for laser cutting and waterjet cutting tools.

Limitations for IP65-rated Servo Motors

Despite their strengths, IP65-rated servo motors aren’t ideal for all industrial applications. For example, if you intend to use one for outdoor applications, the motor will require additional protection to shield it from harsh weather. Motors with an IP65 rating have some liquid resistance but are not fully water submersible. And some applications have strict washdown requirements that IP65-rated motors will not meet without additional protection options.

As always, working with a trusted servo motor manufacturer is the best way to address these limitations and find an ideal solution for your needs.

DL3 Servo Motors for Industrial Applications

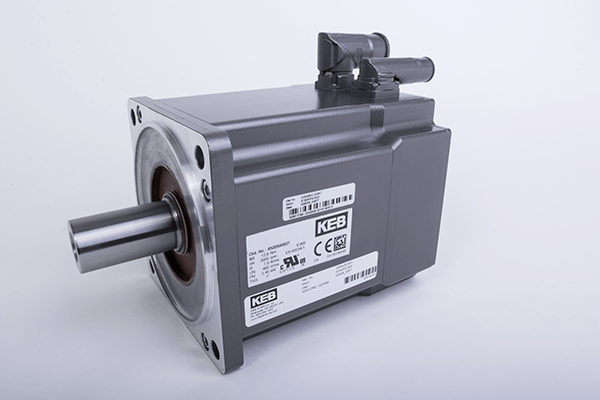

KEB DL3 servo motors deliver dynamic control for even the most demanding cycling and positioning applications. These IP65-rated motors can be outfitted with a range of feedback and brake options to suit your specific requirements and are provided with rotatable connectors for maximum versatility.

KEB AC synchronous servo motors feature outstanding torque density for their size thanks to their neodymium permanent magnets—as well as special IP and paint protection for outdoor and washdown applications. Our DL3 motors are available in two voltage classes (200V and 400V) with an operating temperature of -20 to 40° C, offering up to 70Nm nominal torque and 245Nm peak torque.

Upgrade Your Application with KEB Servo Motors

KEB is a global leader in next-generation control and automation solutions, including servo motors for industrial applications. Our experienced engineers will help you select the optimal motor to drive efficiency and safety for your machine. Contact us today to learn more about how we can address and solve your automation challenges together!

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.