Drive Functional safety for machinery doors, gates, and latches

Safe Speed Monitor (SSM) with level f=0Hz is a TÜV-certified safety function available in KEB’s drive portfolio. It is used to quickly stop an inertia load and ensures the motor is stopped before providing an output back to the safety controller. It is commonly referred to as a safety gate or safety latch function where an operator is frequently opening an access door on the machine. This post gives an overview of using the SSM function in the KEB G6 drive in a sample saw application.

What is SSM and why is it needed?

KEB has a long history of supplying drives for saw applications. In particular, KEB has extensive experience in woodworking, metalworking, and food processing applications where cutting is involved. These machines provide a unique challenge. They can have a large high-inertia saw or blade that cuts material. However, the machines often require human operator access so they cannot be completely guarded or isolated away from contact. An operator might need to frequently access the machine to change the blade or clear blockages.

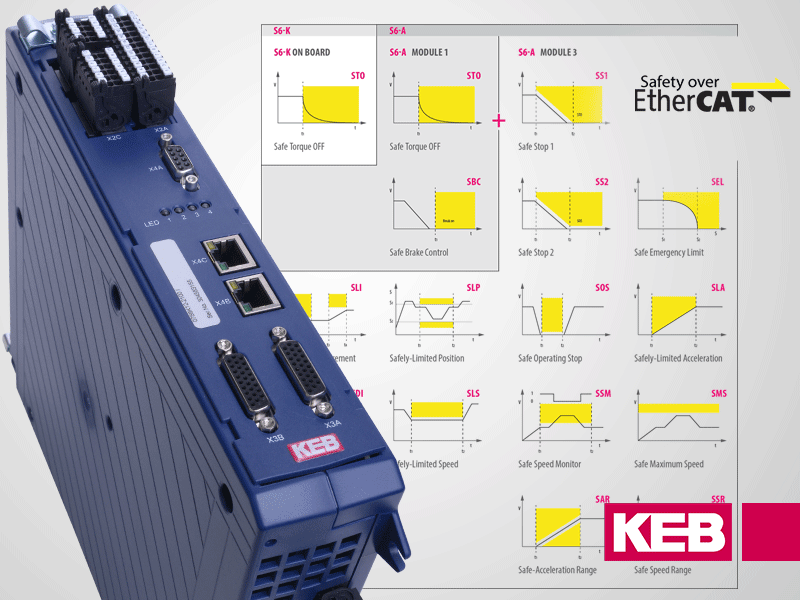

A useful drive safety function for this application is Safe Torque Off (STO). A drive’s STO function provides dual inputs to the drive. Both inputs are needed in order for the drive to output current to the motor and develop motor rotation. This feature can be used to ensure the motor (and saw blade) will not start-up unexpectedly due to a single-path failure. It is typically reliable to a SIL3 level.

STO serves a good purpose when the blade is stopped. But what about when a high inertia saw blade is spinning, then what?

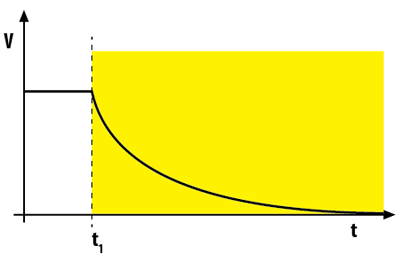

If STO is applied to a large spinning blade, the motor will not develop any torque and the inertia of the blade will cause it to continue to spin until friction stops it.

A freewheeling blade is not a safe situation when a human operator is involved so the access door or gate will often have a safety latch that prevents the door from being opened while the saw is rotating. The downside is that a freewheeling blade can take a long time to come to a stop. This could cause a lot of wasted production time if the door is frequently opened. Or worse yet, cause an operator to work around the safety mechanisms of the machine design.

A better solution is KEB’s SSM f=0Hz functional safety solution which builds on the STO function.

How does it work?

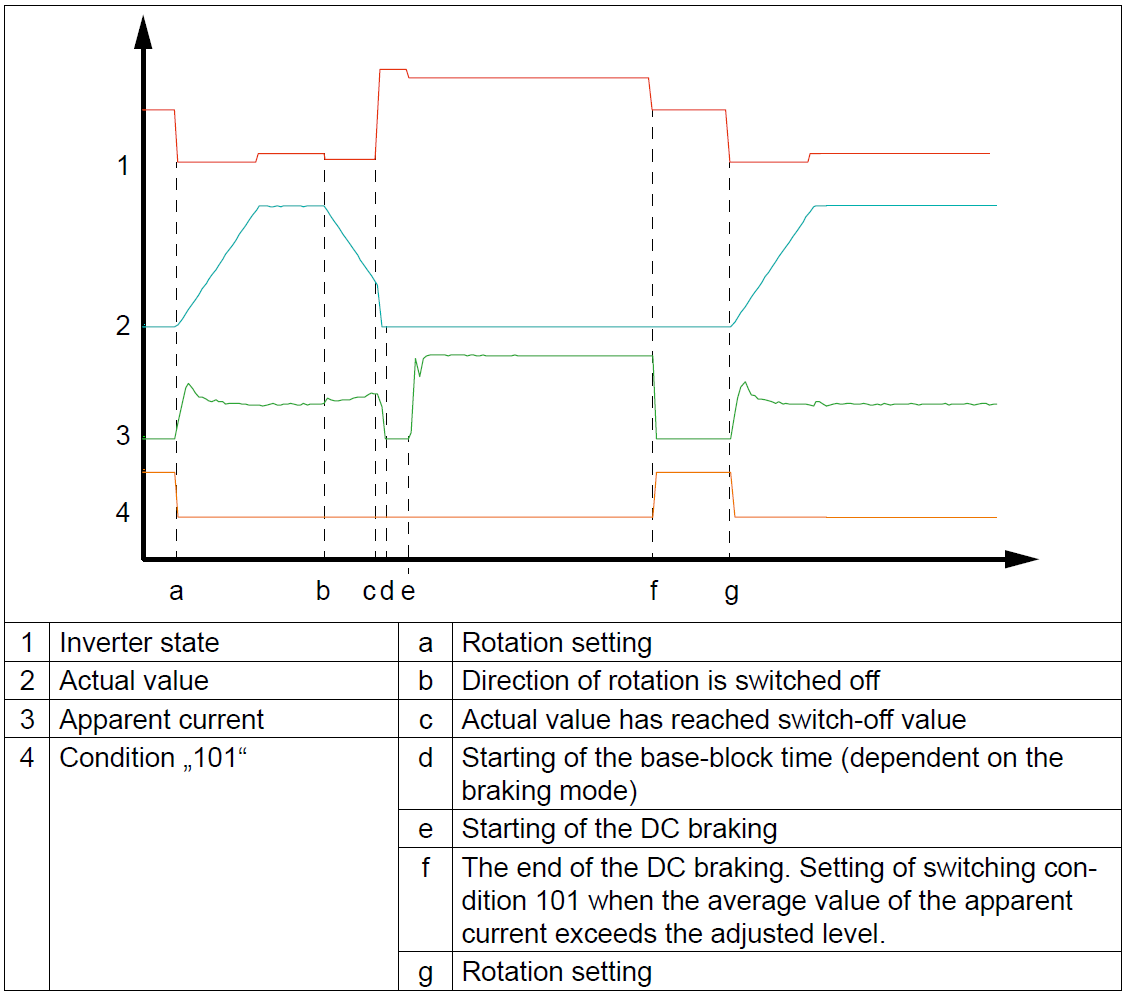

SSM f=0Hz uses a relay output to indicate that the motor is stopped which can then be used to unlock the door in the cutting application described above. Before this output comes on, the drive will: decelerate the motor with ramps, apply DC braking for a minimum of two seconds, and then switch off modulation.

In addition, it will perform a check to make sure a defined current was flowing during DC braking and no errors occur. Only after all these steps are carried out will the relay output display that the motor is at a safe standstill.

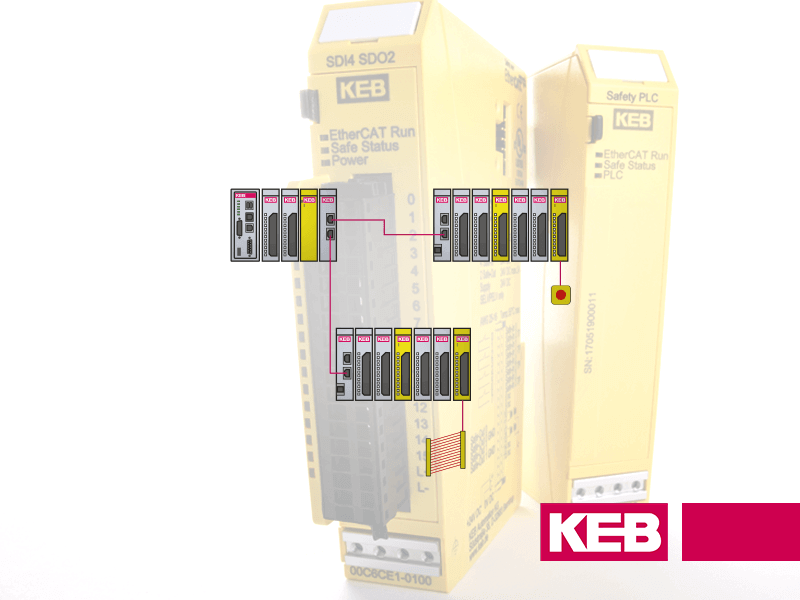

KEB’s SSM function is independently certified by a safety approval agency (TÜV Rheinland) which will help a machine builder as they carry out the risk assessment of their machine.

G6 Benefits

Using KEB’s G6 drive with SSM f=0Hz is a cost-effective way to minimize safety risks because it eliminates the extra cost of a safe encoder, safe encoder input module, and cabling. It is sometimes referred to by our customers as an “Open Loop Functional Safety” feature.

Not many drive manufacturers offer an open loop FS feature like SSM. But when applied correctly, it is a great tool for machine builders.

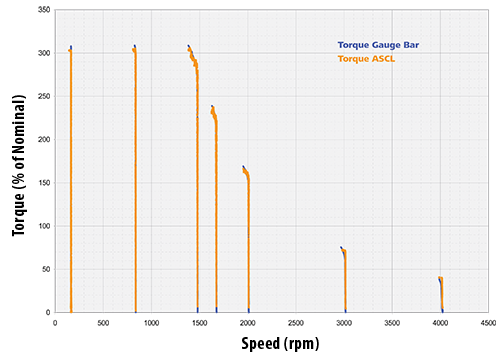

The G6 also is offered with Asynchronous Sensorless Closed Loop (ASCL) control and can provide the same closed-loop speed and torque control without the need for encoder feedback. ASCL also uses a “Torque Approximator” in the control loop which means it can measure torque which can help detect and avoid jam conditions.

The SSM f=0Hz safety function and ASCL control in the KEB G6 provide the perfect combination of performance and safety in a cost competitive drive.

Contact an Applications Engineer at KEB America today to see if the G6 drive with SSM F=0Hz is the right fit for your machine.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.