KEB T6 Auxiliary Inverter Offers Flexible Installation Possibilities

The commercial electric vehicle industry is rapidly growing, and with this growth, the requirements and needs of the market are constantly evolving. While some fleets prefer retrofitting ICE platforms to electric, others prefer platforms designed to be electric from the outset. This variety results in a lack of standardization for the use of space in commercial EVs. This is why solutions with flexible installation possibilities are crucial during design and production cycles.

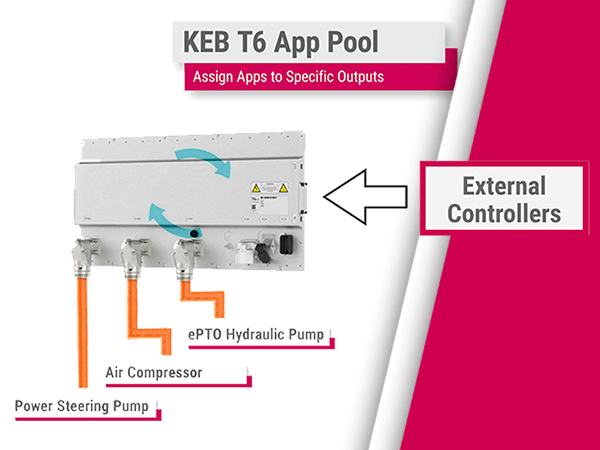

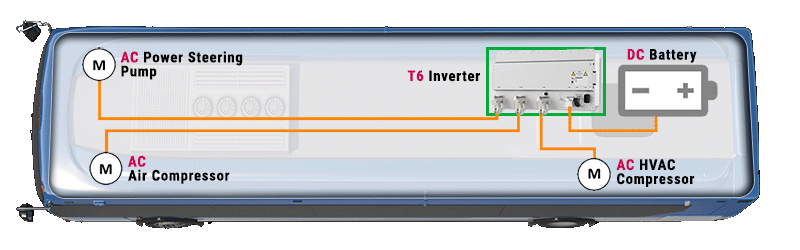

The KEB T6 is a multi-axis, modular auxiliary inverter system designed specifically for commercial hybrid and electric vehicle applications. With the changing needs of OEMs and system integrators in mind, the T6 is designed to be one of the most flexible inverter platforms on the market in terms of system power configurability and installation options. Whereas other articles discuss the power hardware, this article will focus on the housing and connection hardware from an installation standpoint.

Learn more about T6 scalable and modular power modules:

How a multi-axis auxiliary inverter solution can benefit your EV design

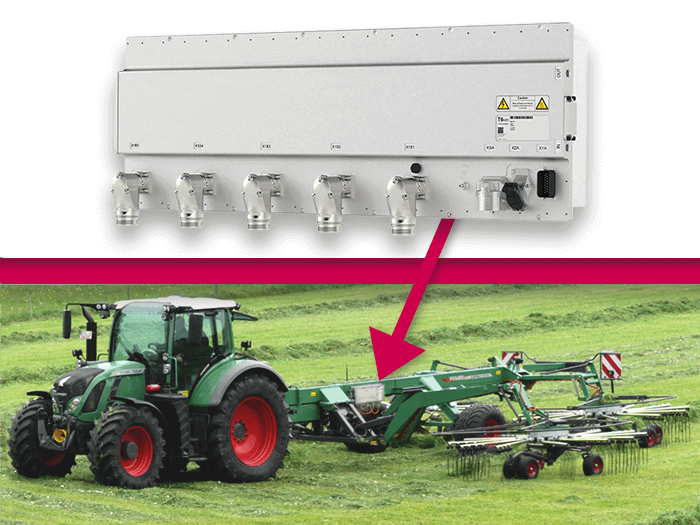

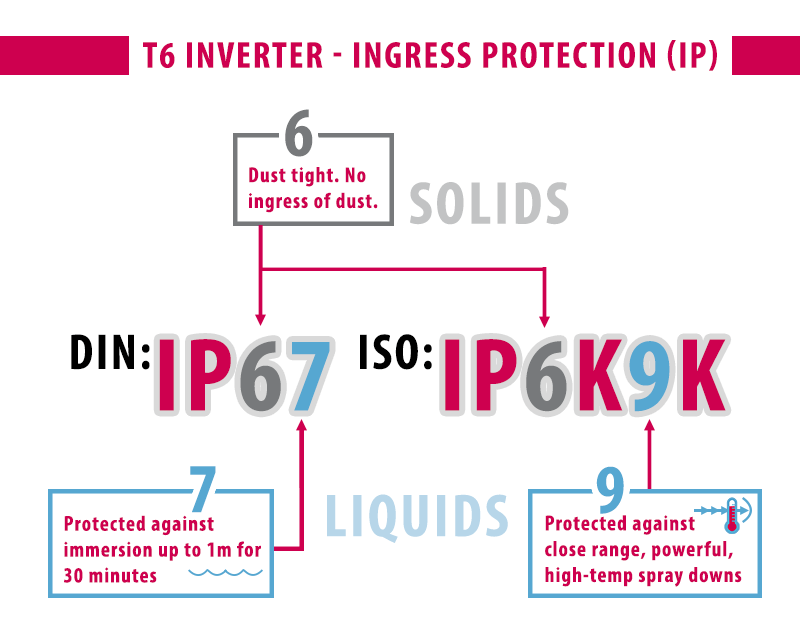

IP67 Rating for External and Chassis Mounting

To start, the T6 housing and connectors are IP67 / IP6k9k rated, making it completely shielded against dust, protected from contact, capable of withstanding temporary submersion, and resistant to high-pressure/steam cleaning. Not only does this make the T6 incredibly reliable in normal vehicle usage, but it also allows the T6 to be mounted externally if space is limited within the vehicle.

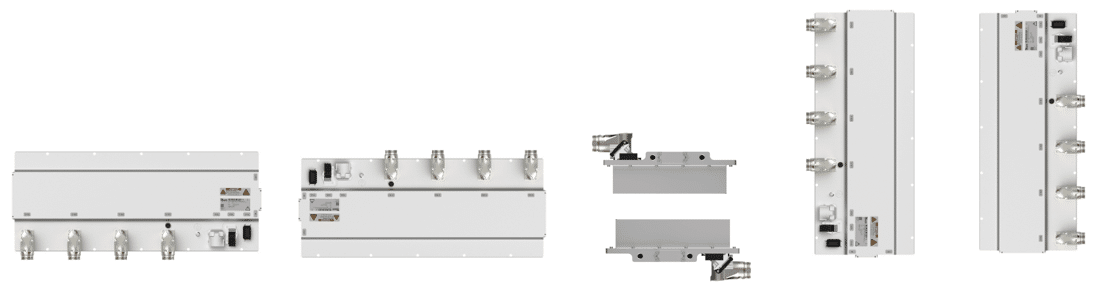

Flexible Mounting Positions

The T6 is also designed to be flexible in terms of mounting positions. Its rugged internal construction allows it to withstand the harsh shock and vibration conditions experienced by commercial on and off-highway vehicles. This ruggedness also gives the T6 the ability to be mounted in any orientation, so it can be mounted sideways, upside-down, or however it is needed. This makes it easier to find a mounting location that fits within the available space in the vehicle.

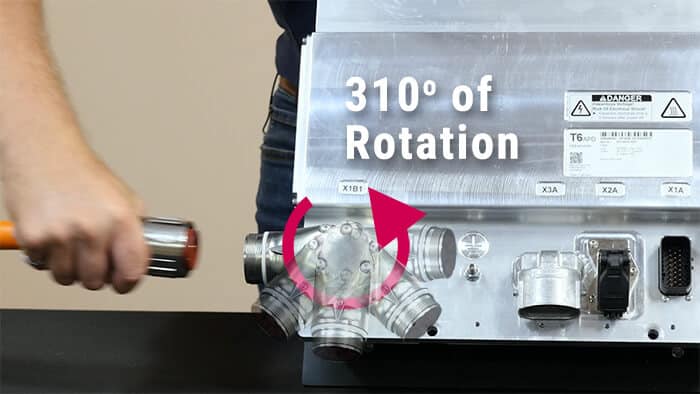

Rotatable Connectors

Another thing that makes the T6 flexible is its rotatable connectors for the AC outputs. These rotatable connectors allow the T6 to fit into tight spaces where obstacles might otherwise push up against the motor cables and cause them to bend to a dangerous degree. Additionally, the rotatable connectors make it easier to route cables as needed, avoiding entanglement and ensuring reliable operation.

Up to 30m Motor Cables

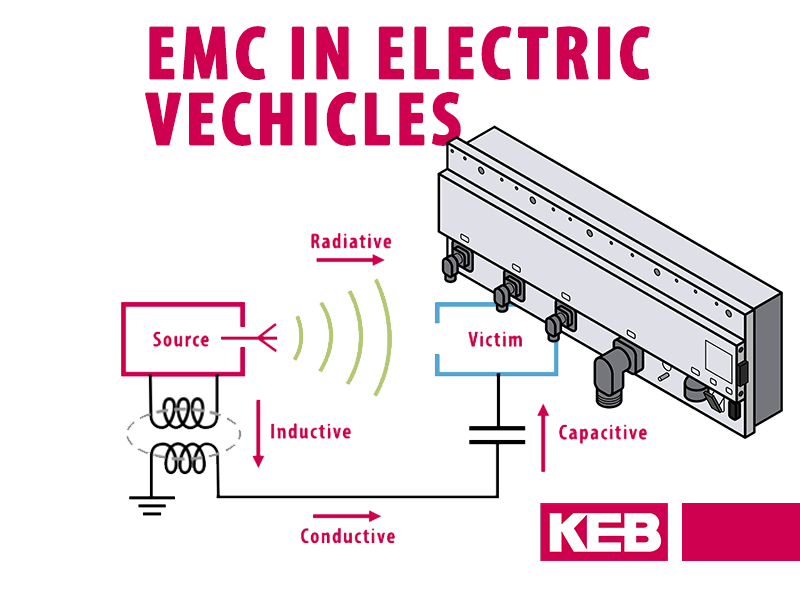

The T6 was designed with electro-magnetic compatibility (EMC) as a primary concern and employs EMC strategies that allow it to support motor cables up to 30 meters per inverter output. This feature also gives the T6 the ability to support design layouts not supported by other inverters.

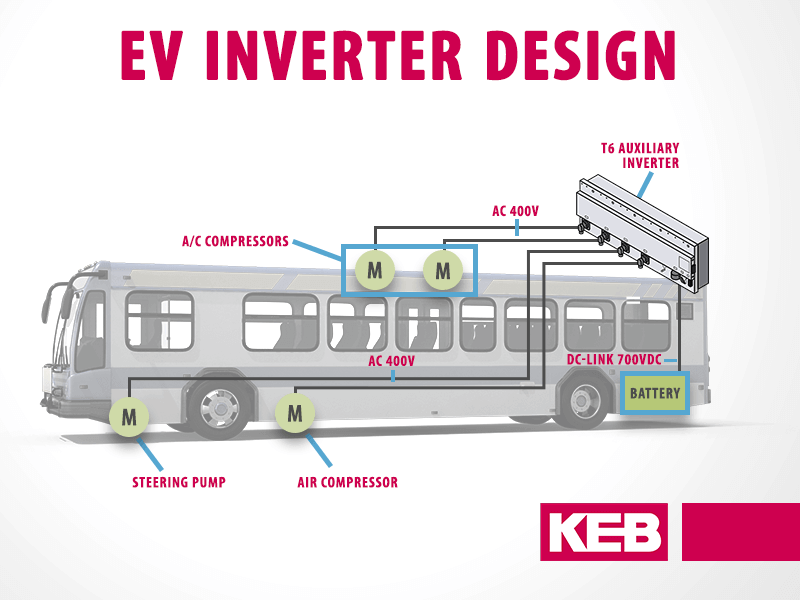

For example, a common design layout is to mount the power electronics in the back of a bus and the power steering pump in the front. Most inverters don’t support such long cable runs, requiring the inverter and motor to be installed close together. The T6 doesn’t have this limitation and can be mounted in a central location far from the motors it drives. This offers greater flexibility and saves on costly HVDC cables and long low voltage runs.

Conclusion

Installation flexibility is an essential asset in the rapidly evolving commercial EV industry. The KEB T6 auxiliary inverter offers a flexible platform for auxiliary components, freeing up more space and engineering time for core components such as the battery and traction equipment. If you are interested in learning more about your options for powering auxiliary components in commercial EVs, contact a KEB e-mobility applications engineer for more information.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.