Why Permanent Magnet Brakes Work Best for Servo Motors

In servo motor applications where precision and efficiency are paramount, permanent magnet brakes emerge as a critical component. Their distinct advantages are undeniable, offering unparalleled efficiency and accuracy.

These factors make them an essential element in various demanding applications, where they contribute significantly to servo systems’ overall performance and reliability.

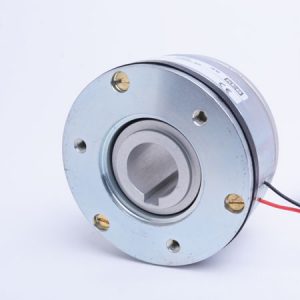

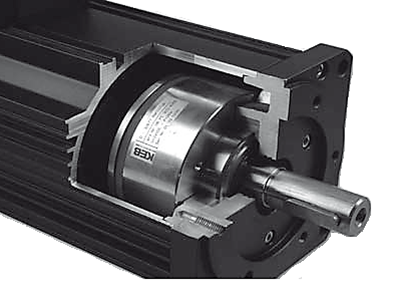

Servo motor applications often require integrated servo motor brakes for static (holding) braking or emergency stops. KEB offers servo motor brakes up to 145Nm. Integrating the brake into the servo motor housing, rather than externally mounting it, saves on overall system design work, space, and ease for the customer.

The servo motor industry is trending smaller in motor design but still demands the same or better performance concerning efficiency and torque.

How Does a Permanent Magnet Brake Work?

Permanent magnet brakes use magnetic fields to create a robust and reliable braking mechanism. When the electromagnetic coil within the brake is energized, it creates a magnetic field that attracts the armature, disengaging the brake and allowing free rotation of the motor shaft.

The magnetic field collapses upon de-energizing, allowing the brake to engage swiftly and securely. This mechanism ensures dynamic performance and high precision, crucial in applications requiring exact motion control.

What are the Different Types of Servo Brakes?

Servo brakes come in various forms, each suited to specific applications. The most common types include permanent magnet, induction, and DC motor brakes.

- Permanent Magnet Brakes: These are known for their compact design and high efficiency. They are ideal for applications where space is limited but high performance is required. Their operation is based on permanent magnet DC technology, which ensures a quick response and high torque in a small package.

- Induction Motor Brakes: These brakes are typically used in applications where the motor runs continuously, and braking is required only for stopping or holding. robust performance in heavy-duty applications.

- DC Motor Brakes: DC motor brakes are versatile and can be used in various applications. They are particularly effective in applications requiring variable speed control and rapid stopping.

KEB’s Permanent Magnet Brake also called a PM brake, is a proven solution that works effectively and safely when integrated inside a servo motor. If you want to know how a Permanent Magnet Brake operates, the video (above) gives an overview.

While permanent magnet brakes excel in compactness and response time, induction motor brakes are often utilized in scenarios where continuous operation and robustness are essential.

Unlike permanent magnet brakes, ideal for precise control in smaller, more dynamic systems, induction motors are often favored in larger-scale applications where their inherent characteristics, such as higher starting torque, play a vital role.

Advantages of KEB PM Brakes

KEB’s permanent magnet brakes have many advantages over traditional spring-set types. They offer lower inertia, high maximum speeds, and backlash-free operation.

Their quick brake engagement and highest torque density (torque to diameter ratio) make them ideal for dynamic applications. With ISO Class F or H insulation and a flexible design for integration purposes, these brakes are efficient and versatile.

In the context of closed-loop systems, our permanent magnet brakes excel in providing precise control. This level of control is critical in applications where exact motion control is required, such as in robotics or medical machines.

When the brake is applied, it can deliver the needed braking torque almost instantaneously (a few milliseconds), crucial for emergency stops.

In addition to their high torque density and quick engagement, KEB’s permanent magnet brakes are exceptionally suited for closed-loop systems.

Their precision and rapid response complement closed-loop control in servo motors, enhancing accuracy and stability in applications where feedback and continuous adjustment are crucial.

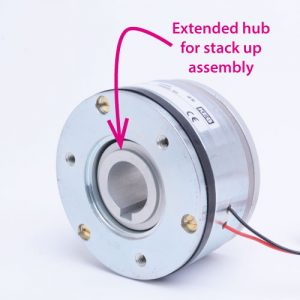

Customized – For Your Motor and Assembly

Applications are becoming increasingly complex and often require customization. We understand this and can work with you on designing an integrated PM brake for your servo motor to make the assembly and design as straightforward as possible while maintaining high safety and performance.

We have proven this technology in the market, and there are certain advantages to why a Permanent Magnet Brake is the correct brake technology for varying servo motor applications.

Our PM brake solution is our highest torque density brake, offering high torque in a small package, which is ideal for these servo motor designs. Compared to spring-set types, KEB PM brakes are approximately 33% smaller for an equivalent torque rating.

Please note that if the application absolutely requires a fail-safe brake, then you would need a KEB Spring-Set Brake. However, KEB Permanent Magnet Brakes have been used for applications requiring the highest degree of safety, such as medical surgical robots, and are reliable when installed and operated correctly.

They are currently installed in various applications in thousands of servo motors from different manufacturers worldwide.

KEB offers unique brake designs that ease assembly and integration into your existing systems. Our engineers are ready to collaborate with you to find the right solution for your application, ensuring that your servo motor operates with the utmost efficiency and reliability.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.