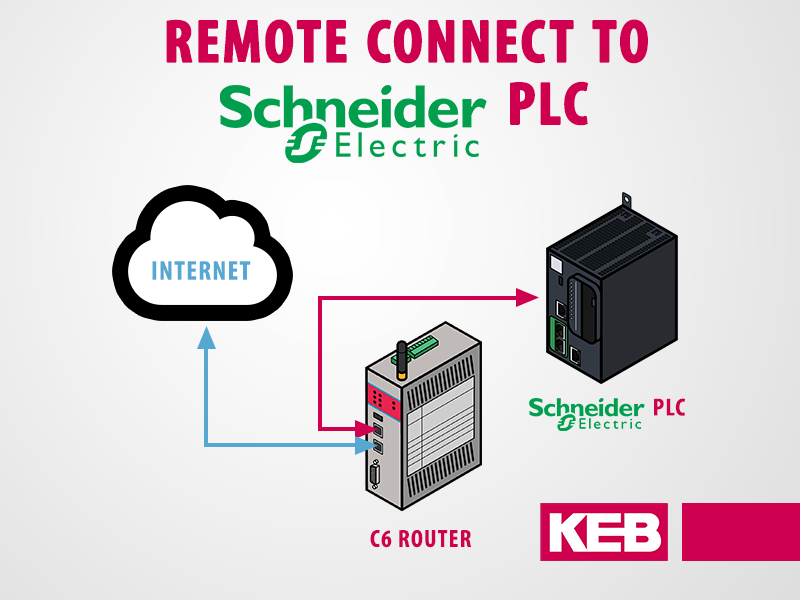

This article will review how to gain remote access to Schneider PLCs. Learn how to configure a KEB C6 Industrial Router and setup a VPN connection to a Schneider PLC.

Specifically, we will connect to a TM251ESE PLC using an Ethernet connection but the same process can be used for other models of Schneider PACs. It is also possible to remote program Schneider PLC’s with a serial connection, however, this will not be covered in this blog post.

The necessary hardware and software programs are :

- Combivis Connect

- C6 VPN Router

- Schneider TM2511MESE PLC

- SoMachine 4.3

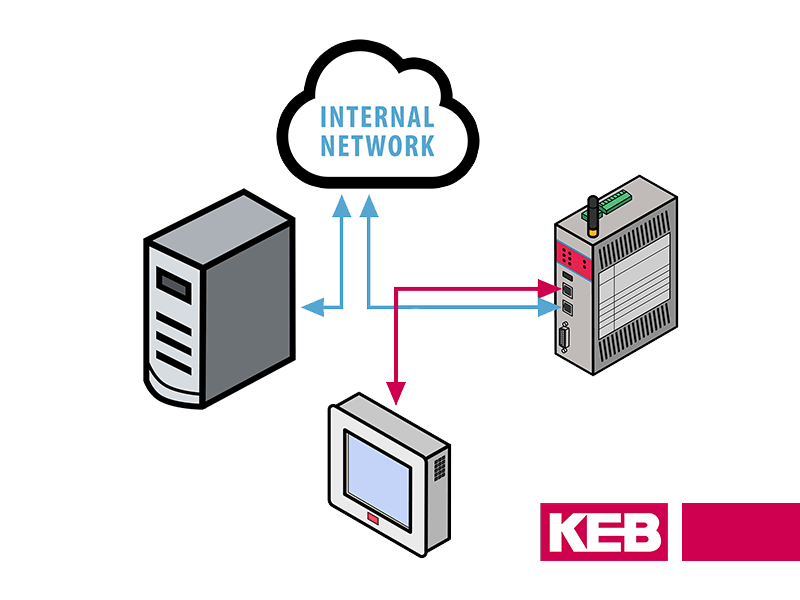

System Architecture

Router Configuration

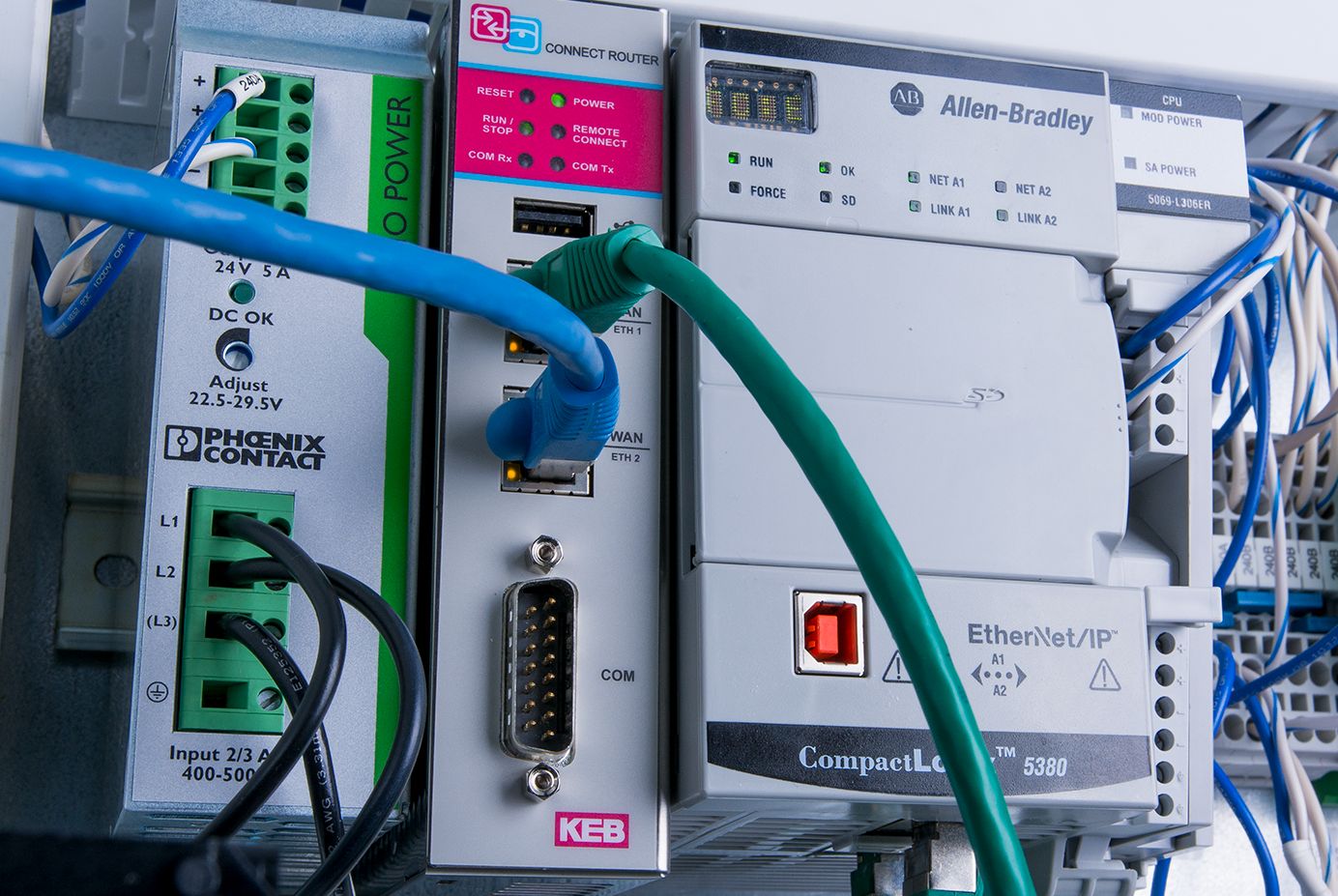

The C6 Router can be configured using two different methods. Configuration is possible using a local network connection or from an exported configuration data file via USB. Regardless of the method used, the required configuration methods will be the same. This example will illustrate how to configure the router using a local network connection.

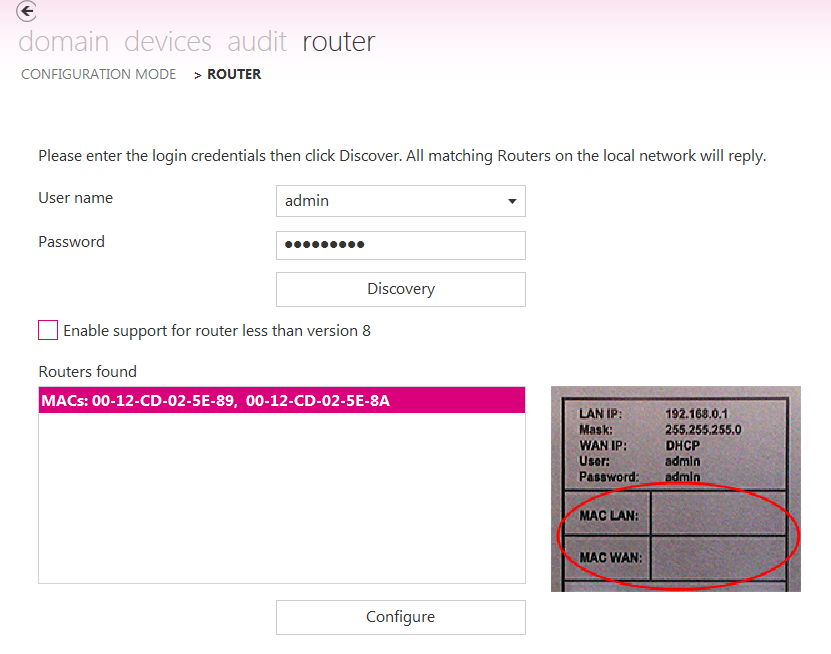

1.Enter username and password and scan for connected router. Once the username and password has been successfully entered the MAC IDs of the router Ethernet interfaces will populate in the “Routers found” window. Highlight the MAC ID and select “Configure”. If this is the first time configuring the router use the default user (admin) and password (admin). The default username and password along with the MAC IDs of each Ethernet interface is printed on the nameplate of the router.

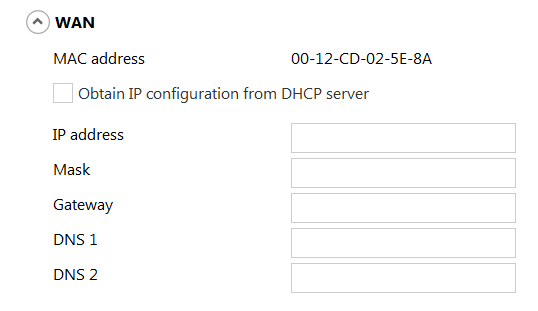

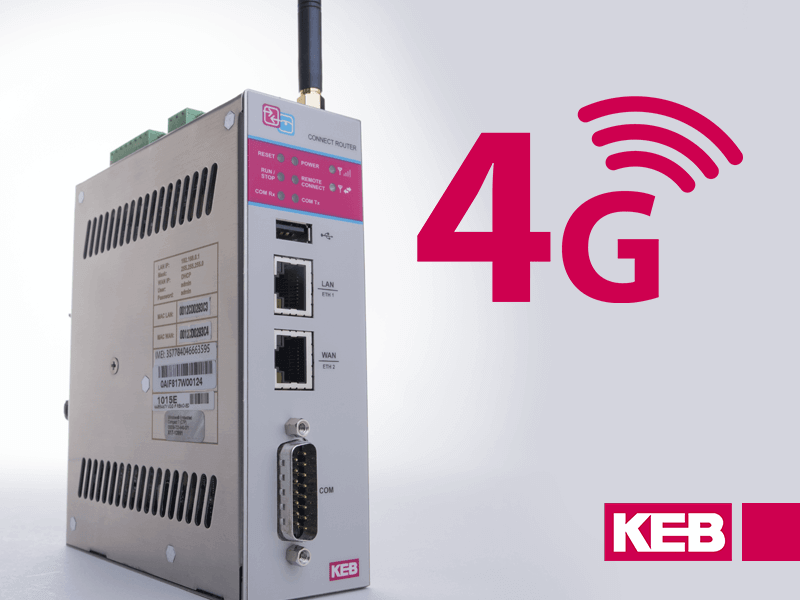

2. Configure WAN Port. The WAN port will be used for internet access. An internet connection is required to setup a VPN connection to the remote PC running Combivis Connect. The C6 Router family can support either wired internet connections or wireless internet connections via cellular networks.

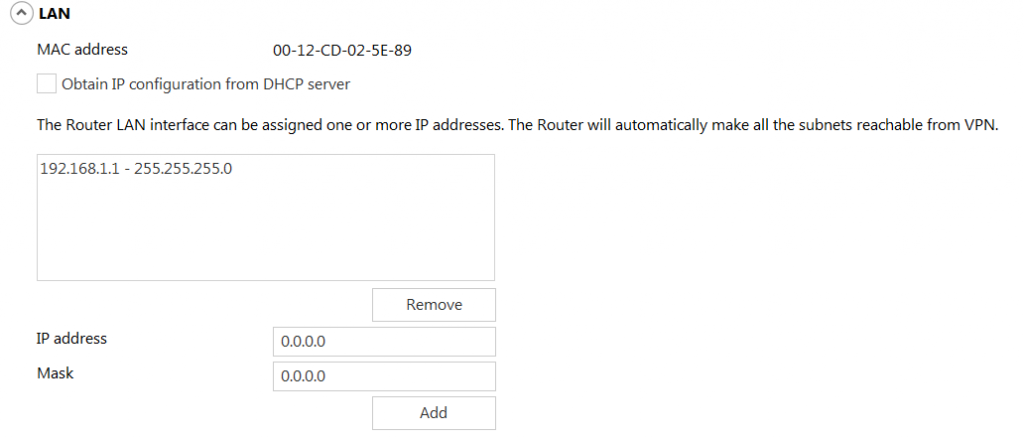

3. Configure LAN Port. The LAN port should be assigned an IP address within the local machine network. It is possible to assign multiple IP addresses to the LAN port to reach devices on separate subnets. Once a VPN connection is established all devices on each subnet will be reachable.

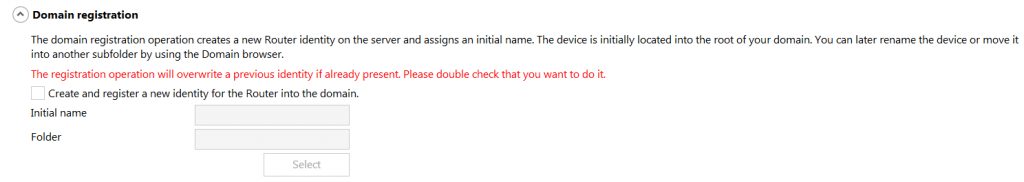

4. Domain Registration. Each router must be assigned a name and location within a licensed Domain. This step is only completed once.

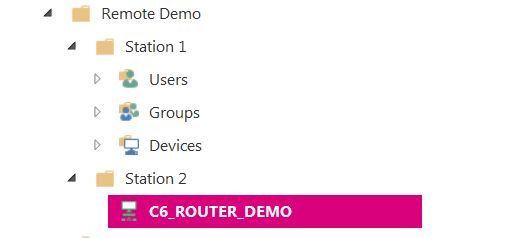

5. Apply Settings and Reboot. Select the “Apply” option at the bottom of the configuration screen. Once the router reboots it will establish appear “Online” in the Domain device tree.

At this point a VPN connection to the PLC is possible. The next section will discuss how to establish the VPN connection to the PLC.

Setting up VPN Connection to PLC

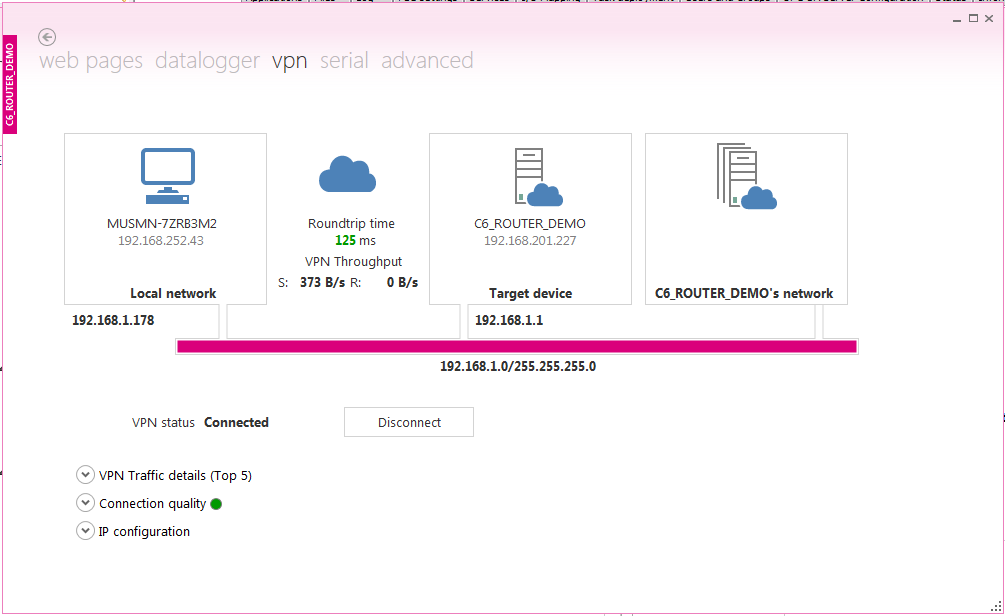

6. Setup VPN connection to C6 Router. Select “Connect” at the bottom of the Device access window or right-click on the C6 Router in the device tree and select “Connect VPN” to establish a VPN connection. Once a VPN connection has been established, the virtual ethernet port utilized by Combivis Connect will be assigned an IP address within the LAN network. All remote devices are now reachable using the VPN connection.

7. Open PLC project with SoMachine software.

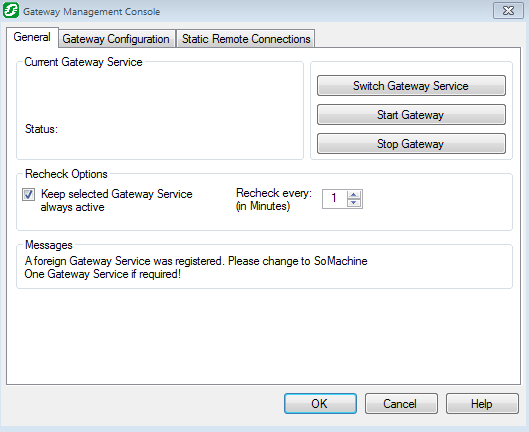

8. Start Gateway. The SoMachine gateway is used to manage the communication between a controller and logic applications. This must be running to connect to the PLC. If the gateway is not running open the Gateway Management Console and select “Start Gateway”.

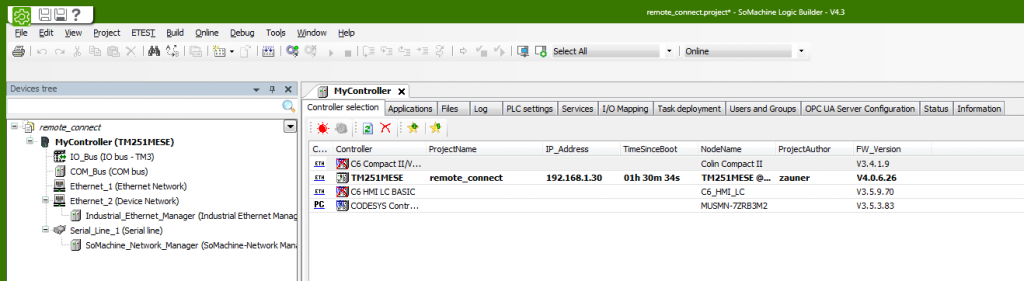

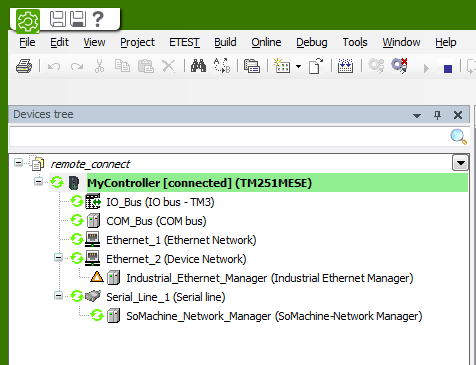

9. Select PLC and Login. In the Devices tree of the SoMachine Logic project, double-click MyController. Next, select the PLC you would like to go online-with. Lastly, Login to the PLC using the Login icon or select Online -> Login from the main toolbar.

It is now possible to remotely program the Schneider TM251ESE PLC using the VPN connection setup by the C6 Router.

Want to connect to your Schneider PLC – Contact KEB today.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.