Advanced Control for High-Speed Motors

One of KEB’s specialties is controlling high-speed motors used on turbo blowers and power generating systems. High-speed motors can operate in excess of 100,000 rpm and typically use air foil or magnetic bearings. Obviously, at these speeds, precise control is required in order to reduce vibration and motor heating. Enter KEB.

This is the first of two parts on how KEB VFDs can be applied in high-speed applications. In this post, we’ll talk about KEB’s unique technology and how it applies to operate high-speed machinery.

The second post discusses some options to optimize performance with high-speed motors.

KEB Control – Advanced control technology for advanced technology motors

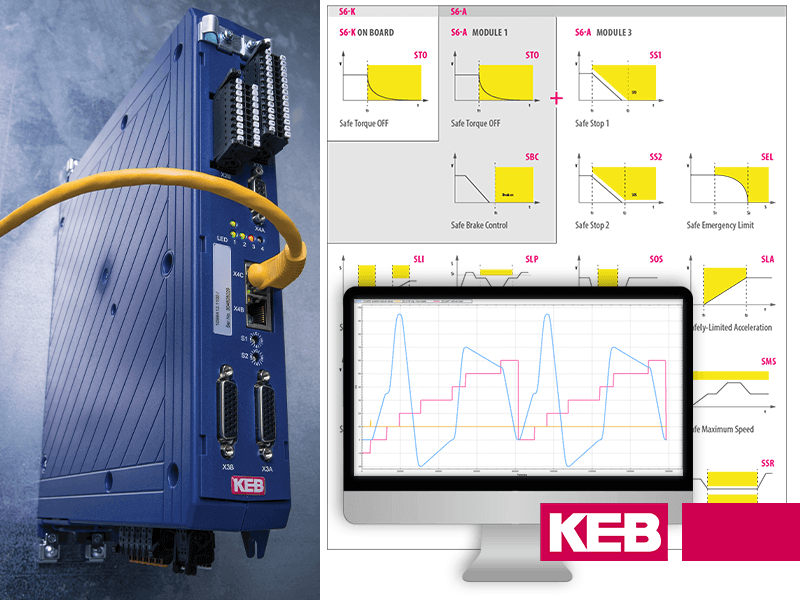

From high-speed spindles and routers to blowers and compressors, KEB’s proven Variable Frequency Drive (VFD) and filter technology provide the control systems to make these applications a success. One advantage of the KEB drive platform is that one drive can operate a variety of different motor types.

High-speed motors, whether a surface-mount permanent magnet (SMPM), interior permanent magnet (IPM), or induction motor, utilize the advanced technology to provide a high power density and high-efficiency solution to the application.

Such advanced motors incorporate advanced technology such as magnet bearings and airfoil bearings. The VFD system to control these motors should also utilize the advanced technology to provide the best performance and highest efficiency of the overall system. KEB drives and filters provide the advanced control technology needed to run these motors effectively and efficiently.

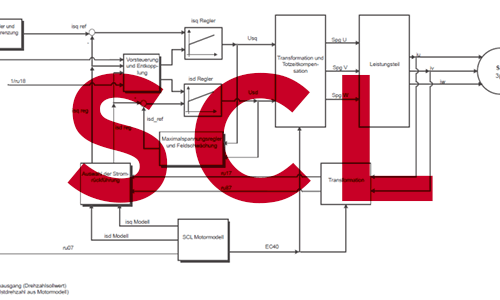

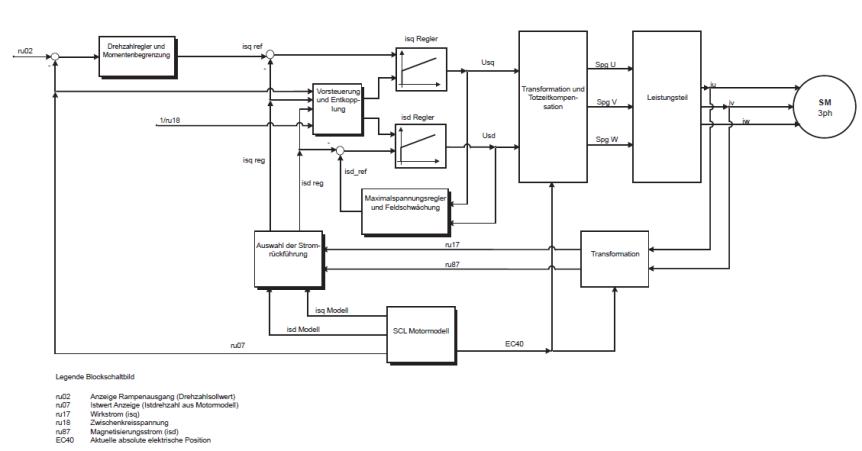

KEB Sensorless Closed Loop™ (SCL) Software – Precise control without feedback

KEB’s Sensorless Closed Loop™ (SCL) software provides precise speed and torque control of SMPM or IPM high-speed motors without requiring a feedback device. The high-frequency output required for typical high-speed applications has the potential to cause adverse effects to the feedback signals, which can affect the control of the motor.

KEB SCL software eliminates this issue by utilizing a high-speed processor and direct measurement of the motor characteristics to build a precise model of the motor. The software uses the output current and back EMF (for PM motors), compares these to the calculated model values, and makes adjustments based on this information, effectively closing the loop internally in the software.

KEB Drives – High output frequency

In addition to the advanced software, KEB drives are available with hardware capable of switching frequencies up to 16khz, depending on the drive size. The higher switching frequency allows the current waveform to approach a sine wave, providing superior motor performance and higher system efficiency.

Learn more: VFD Switching Frequency

Output frequencies up to 1600hz are available. Depending on the motor type and control, motor output speeds of 100krpm have been achieved.

If you have questions about how KEB drives can be used in high-speed applications, contact us today and our applications engineers will be ready to help you.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.