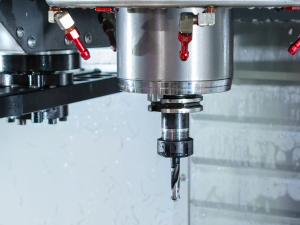

With over 200,000 installed spindle drives, KEB is an expert in high speed motor control and has earned a reputation as the worldwide spindle drive leader. This post describes some of the reasons KEB is preferred by our CNC, woodworking, and robotic customers.

Spindle Motor Control

KEB drives can run both induction and permanent magnet spindle motors through the adjustment of a drive parameter. KEB’s robust motor control algorithms mean it can run a variety of different motor designs from all major spindle motor manufacturers. Basic applications can utilize V/Hz control. The advantage of V/Hz is its simplicity and ease of commissioning.

Closed loop applications can be solved using KEB’s dual channel encoder interface. Many feedback formats are supported including: Incremental TTL/HTL, Resolver, EnDAT 2.1/2.2, Hiperface, etc. Tool change and orientation functions can be programmed in the drive. This possibly allows the PLC or controller to be removed from the system.

Closed loop drives offer the additional feature of torque limits. Different sets can be programmed which allows a number of different torque limits to be set to match the motors operating characteristic – ensuring that the motor does not become overloaded.

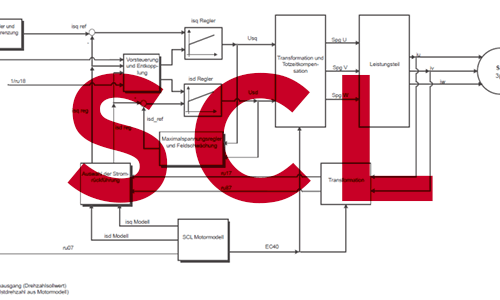

KEB’s unique SCL™ and ASCL™ (Sensorless Closed Loop, Asynchronous Sensorless Closed Loop) control technology can be used to provide closed loop performance without the need for encoder feedback.

Spindle Performance

Newer drive platforms like the S6 feature a fast current control loop of 62.5µs. This provides excellent spindle motor performance and, ultimately, a better final product.

KEB drives are offered in switching frequencies up to 16kHZ with output frequencies up to 1667 Hz for high-speed applications. This allows motor speeds in excess of 100,000 rpm while keeping motor noise and heating to a minimum.

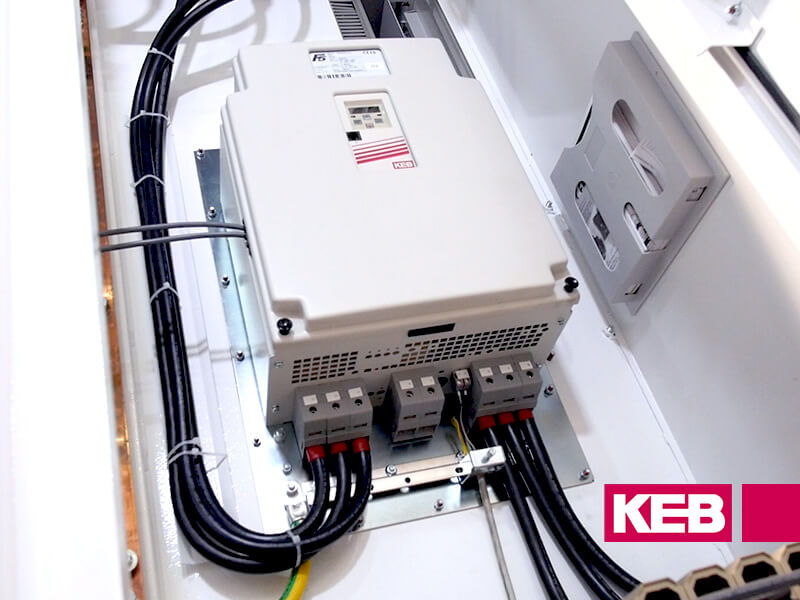

KEB drives are offered in sizes from fractional horsepower up to 1000 Hp. For 3 phase installations, 230VAC and 460VAC voltage classes are available. Additionally, a single phase 230VAC variant is offered.

Ethernet On Board

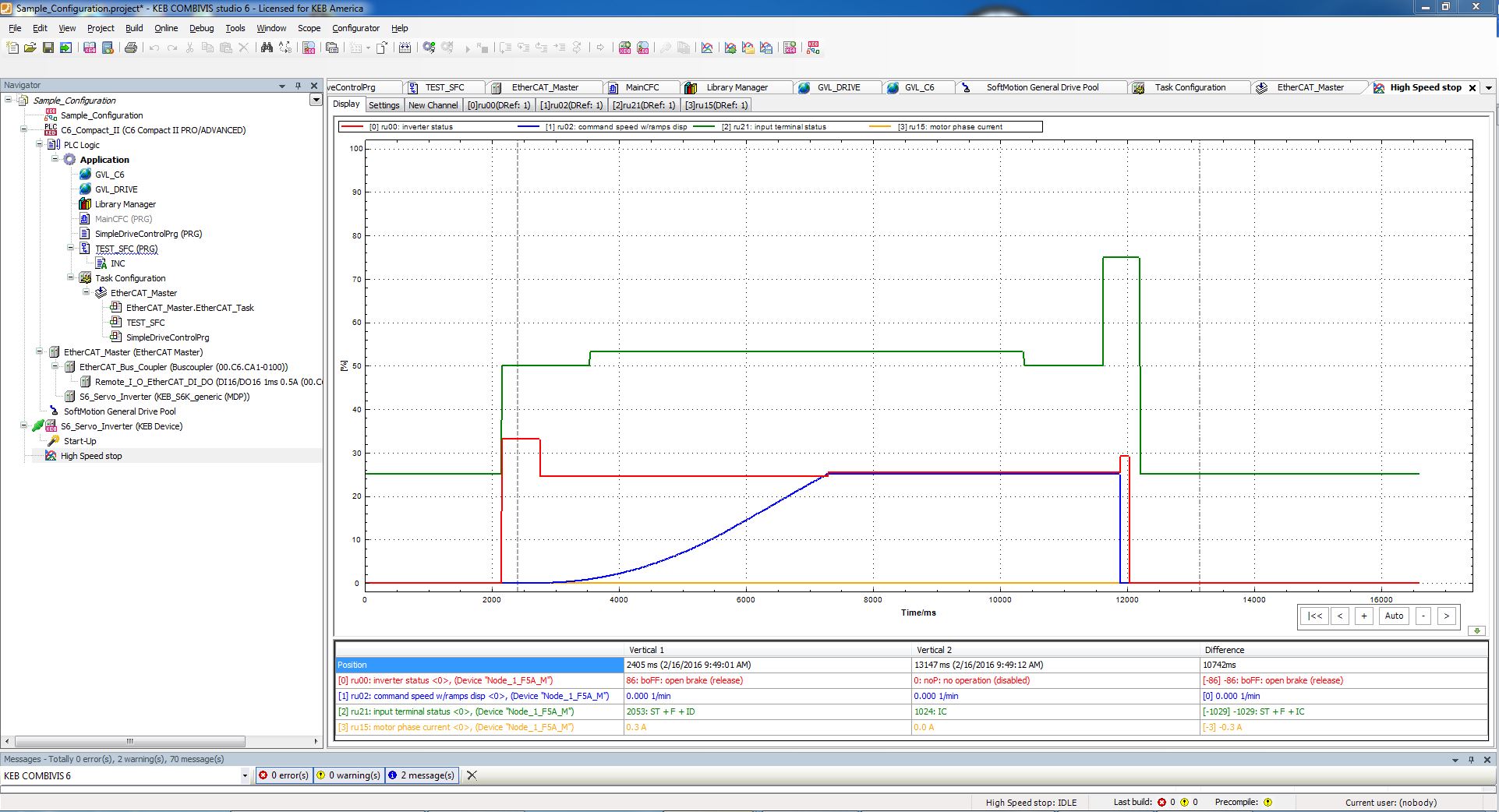

Although KEB drives support a variety of different communication protocols like Ethernet/IP, Powerlink, and Profinet – we have standardized on EtherCAT. EtherCAT communication offers excellent real-time performance, is an open technology with many vendors and members, and offers tremendous value for its performance.

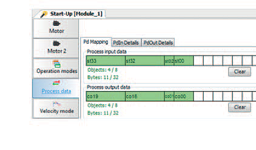

EtherCAT is well suited in demanding, high-performance applications. For example, the S6 platform supports a 500 µs scan time for up to 8 parameters (up to 32 bytes). The EtherCAT process data can be used to send a home or orient command to the drive. This can be used for a basic home start or for a tool change. The S6 drive will use the zero pulse from the encoder to position the spindle for a tool change.

Combivis Wizard for easily configuring EtherCAT Process DataPositioning can also be done over EtherCAT. The desired position (position counts either relative or absolute) can be written to the drive directly over EtherCAT. Alternatively, predefined positions can be stored in the drive and the PLC can select which position the system should move to and send that signal over EtherCAT.

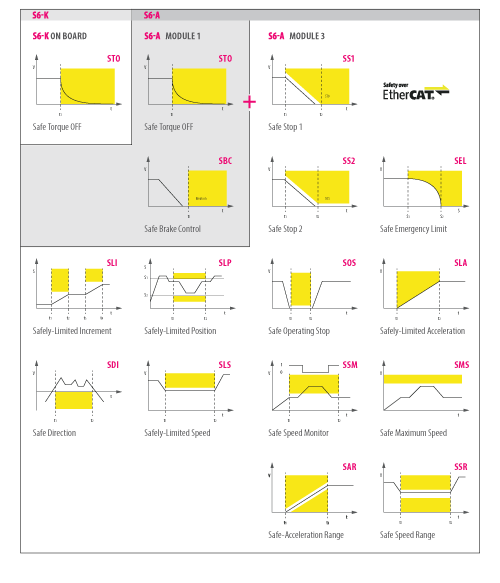

Functional Safety

Along with the benefits of EtherCAT mentioned above, KEB drives also offer functional safety options. Safe-Torque-Off (STO) is offered as standard. More advanced Safe Motion functionality according to ISO 13849 is available, including: SS1, SS2, SOS, SLS, SLP, SLI, SDI, SSM.

One advantage for moving Safe Motion into the drive is that the drive’s high power does not need to be removed in certain situations. An example would be when an operator opens the machine tool door to clear debris. Traditionally, all power would be cut from the drive to the motor does not unintentionally start. But this requires that operator waits so the drive bus capacitors can discharge and recharged again.

With KEB’s SIL3 Safe Motion functions, this same functionality can be achieved through our Safe control card and 24V inputs. High power remains connected which ultimately allows for machine operation.

KEB has over 200,000 installed spindle drives worldwide in the most demanding machine tool, stone cutting, and woodworking applications.

KEB offers various drive platforms that are suitable for spindle motor operation. Single phase and three phase inputs are possible and KEB drives control both Induction and Permanent magnet motor types.

Open loop applications can use basic V/Hz control or KEB’s proprietary SCL motor control. SCL allows extremely precise torque and speed regulation without the use of encoder or resolver feedback. Ultimately, SCL allows for optimal motor shaft performance, lower motor heating and a better finished product.

Spindle applications requiring tool change or orientation functions can benefit from KEB’s closed loop drives with integrated features. KEB closed loop drives feature a Z-pulse input and a 32-bit internal positioning module which makes homing and tool change routines easy to program.

KEB spindle drives are known for their high performance. For example, the new S6 drives feature a 62microsecond current control loop. Modules are capable of output frequencies up to 1600Hz.

When it comes to industrial communication options – KEB offers the most flexibility. Over 10 different protocols are supported including EtherCAT, Powerlink, Ethernet/IP, and Profinet. This allows a machine builder to standardize on just one drive platform even though they might offer multiple control platforms.

See for yourself why KEB is the spindle drive leader.

See why KEB is the spindle drive leader, discuss your application with a KEB engineer today.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.