How Servo Motors Enhance Press and Metalworking Applications

Six Benefits and Considerations of Servo Motors in Press Machinery

Servo motors have proven themselves ideal in many industrial machinery applications. Incorporating servo motors into presses for metal forming, stamping, and bending applications can yield significant advantages. Similarly, ancillary equipment such as front-of-line destackers and end-of-line conveyors can enhance their throughput and safety by implementing a servo system. This article explores the benefits of utilizing servo motors in press and associated handling applications.

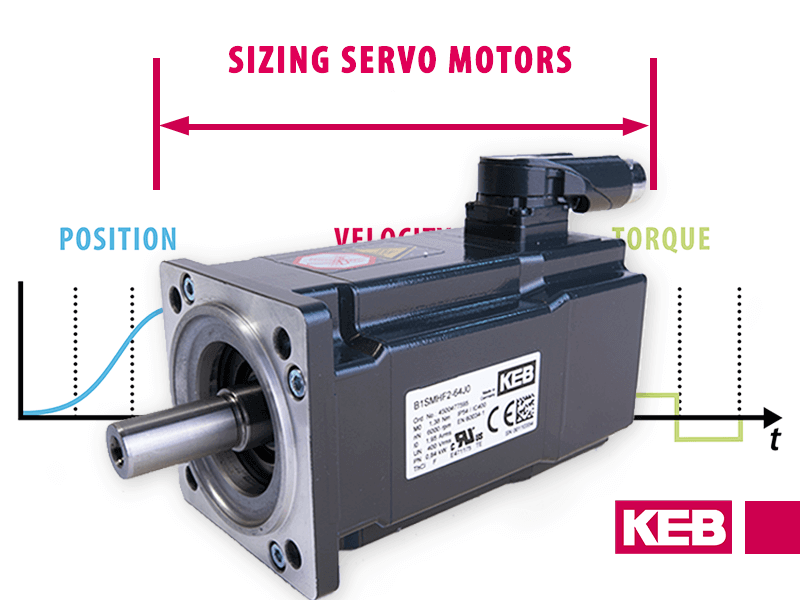

Motor Shaft Performance

Presses often require a high degree of precision and repeatability. Servo motors provide closed-loop feedback, allowing for accurate positioning and torque control at the motor shaft. While induction motors can be fitted with encoders (referred to as “vector motors”), they come with a hefty price premium and exhibit notable limitations, particularly at 0 rpm, necessitating additional forced air cooling. In metal bending applications with precise angles, precise positioning becomes imperative. A drive’s ability to accurately control torque is paramount when precise force control is required.

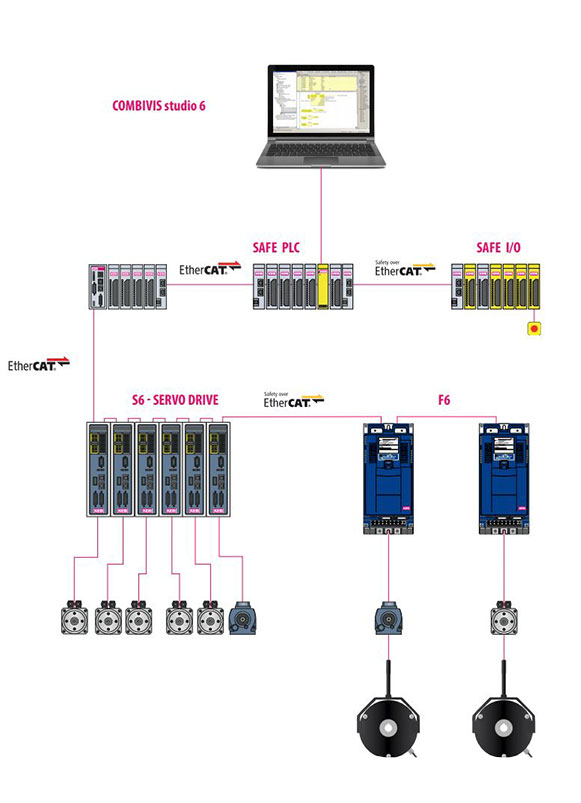

Servo motors excel in synchronizing multiple motor axes, a requirement in scenarios such as transfer press applications where several motors must work together. KEB drives have an internal positioning module that delivers outstanding motion control performance and reduces system expenses, mainly when a PLC does not require a motion controller add-on. When coordinated motion with camming is needed, an external controller like KEB’s C6 Smart controller is ideal. The most straightforward integration occurs via a real-time fieldbus communication protocol like EtherCAT.

Fast Cycle Times

Machines are often evaluated by how many parts they can make during a given period. Therefore, there is always a desire to reduce cycle times. During the machine cycle, the motors accelerate and decelerate quickly. Servo motors are ideal for fast cyclic applications and hold an advantage over induction motors.

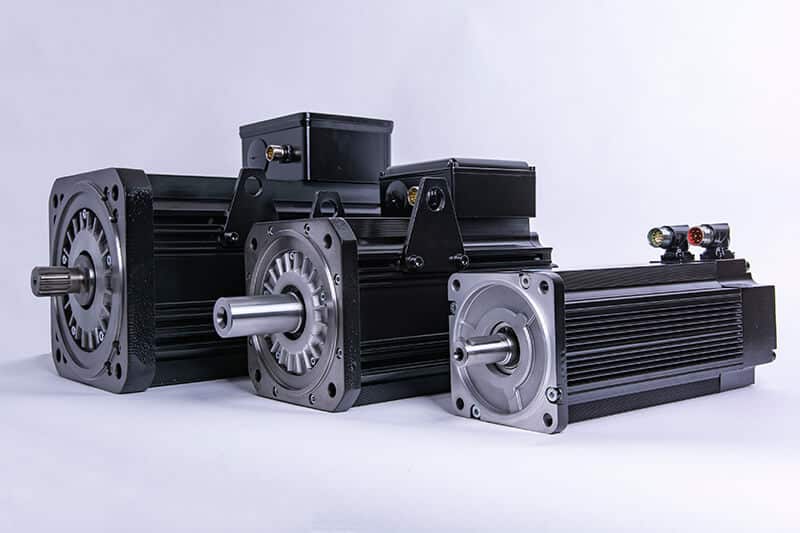

However, choosing the lowest inertia is not always the correct answer. It’s crucial to align the servo motor’s inertia with the load inertia. KEB provides a range of servo motor products tailored to various inertia requirements. This alignment between motor and load inertia ensures the most effective system response. For example, KEB’s DL3 motors are suitable for low-inertia applications, while the DL4 and TA servo motors are more appropriate for medium-inertia applications seen on many presses.

Energy-Efficient Servo Motors

Metalforming and stamping represent energy-intensive processes, often necessitating substantial power due to the nature and scale of the materials involved. These operations typically require powerful motors, and when these motors operate at high-duty cycles, a significant amount of energy is consumed. Consequently, the ongoing electrical energy operating costs over the machine’s lifespan tend to exceed the initial machine acquisition cost.

In contrast, servo motors are more energy efficient than their induction motor counterparts. Motor efficiency improves with both motor types as motor power increases. Notably, Permanent Magnet (PM) servo motors can outperform induction motors by several percentage points in larger sizes. While this might appear modest, the cumulative effect of this enhanced efficiency translates into substantial energy savings throughout the machine’s operational life.

Servo Motors – Part of the Safety Solution

As mentioned, lowering cycle times is always desired. Therefore, robotics are increasingly being used to manage the infeed and outfeed of material to the press. In addition to reducing cycle times, another compelling rationale for deploying robots is the inherent safety risks associated with presses and similar machinery when operated by humans. These motorized applications often expose operators to hazards such as cutting, crushing, pinching, burning, etc.

To address these safety concerns, the industry is increasingly adopting Performance Level (PL) components. KEB servo motors, for instance, offer the option of SIL2/PLd motor encoders, which can be further assessed using a safety controller or safe motion drive, thereby enhancing the overall safety and reliability of the machinery.

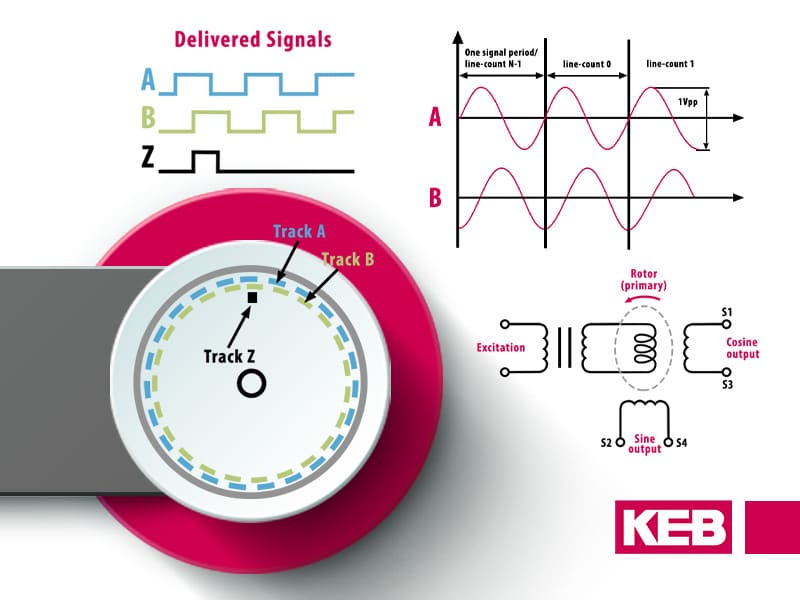

Motor Feedback Options

Servo motors rely on shaft feedback to precisely regulate position, torque, and velocity. KEB servo motors offer a range of encoder technologies to cater to diverse application requirements. The standard feedback option for servos is resolvers, known for their robust and shock-resistant performance.

However, some applications might require more precision so an absolute encoder might be used that can provide extremely fine resolution (e.g. >500,000 counts per motor revolution). These absolute types can be selected in single-turn and multi-turn variants. The multi-turn encoder allows the motor shaft position to be known even in the case of a loss of power or machine restart, meaning the machine does not need to “rehome” during a power cycle. This is especially interesting for critical machinery that could experience frequent power cycles or changeovers.

High Overloads

Presses are machines that require high overloads during the machine cycle. This is where servo motors excel, as they can deliver peak torque levels ranging from 350% to 500% when required. In contrast, depending on their specific design, induction motors may only reach as low as 200% of peak torque (breakdown torque). The superior peak torque capabilities of servo motors contribute to a more space-efficient overall configuration, greatly enhancing the machine’s overall design.

Summary

Servo motors offer many benefits for machine performance, especially in demanding applications like stamps and presses. The performance improvement comes from various factors, including superior motor shaft performance, a more compact package, and better inertia and motion control system optimization. Over the years, the cost premium associated with servo systems has reduced, and they are increasingly economical considering their advantages.

Contact a KEB engineer to discuss incorporating servo motors into your application.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.