How Large Servo Motors Are Transforming Industrial Machinery

Servo motors are commonly used in demanding, high-performance machinery like packaging machines and robotics. Most early adopters of servo motors in machinery have been in low-power applications (5kW and below) where the performance benefit (e.g., machine throughout) and ROI calculations are more easily done.

From Sticker Shock to Superior Performance: Large Power Servo Motors Become a Difference Maker in Industrial Machinery

Many large power applications that have traditionally used induction motors have been reluctant to change because of the “sticker shock” of the servo system (motor and amplifier). However, KEB and other industry players are noticing an increasing interest among machine builders actively searching for ways to differentiate their machines and ultimately lower the lifetime cost of the motion control and motor system.

Machine builders should consider these six things when considering adopting large power servo motors:

Performance

This one is relatively straightforward and should be advertised by the machine builder as a selling point for their machine. Performance is measured by the amount of final product that is delivered over a period of time. Examples include bottles/min, cartons/min, and cycles/hr.

Servo motors offer fast acceleration and deceleration capabilities, so they are particularly well-suited for fast cyclic applications like die cutters, presses, and indexers.

A product that needs to be scrapped due to being out of specification should not be counted in the throughput calculations. Servo motors offer better positioning and torque and speed regulation, which results in a better final product with less scrap.

Downtime and planned maintenance should be factored into the calculation of throughput. Machines requiring manual adjustments and calibration may exhibit lower productivity than those that can automatically reposition and self-adjust as needed.

The key point to remember is that while a large servo system may have a higher initial cost, it can still be a cost-effective choice if it results in enhanced quality and quantity of finished products.

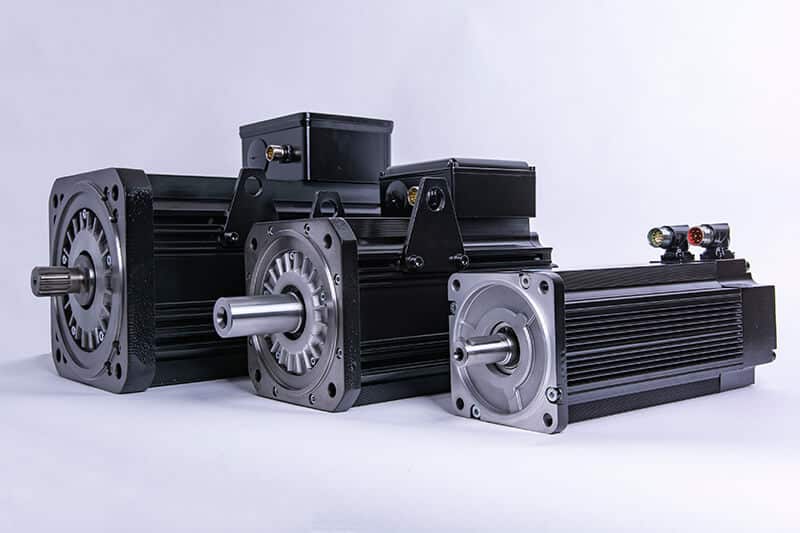

Size and Weight Matters

Factory space is often at a premium, so emphasis should be placed on compact, capable machines. Large PM servo motors are inherently smaller than similar power-rated induction motors. These smaller motors result in a reduced machine footprint, thus allowing for more machinery to be placed within the factory space and increased production output before the need for an expensive facility expansion arises.

Ingress Protection

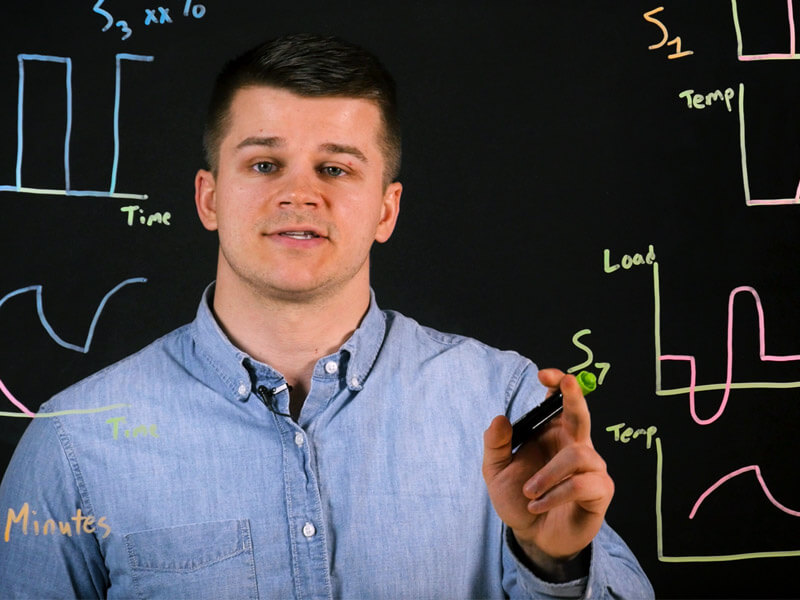

Servo motors offer full torque at 0 speed. They often carry nameplate torque ratings that allow them to be used indefinitely (S1 duty) at 0 speed. This is very different from standard induction motors that use a fan to cool the motor.

Most induction motors use TEFC (totally enclosed fan-cooled) motors where the fan is mounted to the motor and spins as fast as the motor shaft. Reducing the motor speed with a VFD causes the fan to spin more slowly and provides less cooling to the motor housing. A separately powered fan can sometimes provide a constant airflow around the motor, even at lower speeds.

However, this comes with two significant disadvantages: it requires a separate and constant power to motor fan, and the additional fan sometimes reduces the overall ingress protection rating of the motor. Since servo motors do not have such a fan, they are often rated IP56 and IP65 due to sealing on the non-drive end.

Liquid-cooled Servo Motors

Machine builders in demanding applications like extrusion and injection molding have long acknowledged the benefits of employing liquid-cooled drives and motors.

Liquid cooling offers a more efficient means of cooling both the motor and the associated power electronics, thereby enabling greater power throughput from the motor/drive combination.

Like the Brusatori motor, liquid-cooled servos can be seamlessly paired with a KEB liquid-cooled VFD for optimal performance.

Large Power, High Torque Motors

Innovative machine builders are increasingly using unique servo motor designs. One of these technologies is high-torque motors. High-torque motors are servo motors engineered with an exceptionally high pole count, leading to lower output speeds but heightened torque.

This can be advantageous because it might allow the power transmission system to be replaced. Mechanical gearing belts and pulleys have backlash and should be avoided in demanding cyclic applications with aggressive acceleration and deceleration profiles. In such cases, direct-drive servo motors, free from backlash, are the ideal choice for applications requiring precision.

Energy Savings

Another crucial factor that is overlooked pertains to the motor’s energy consumption throughout the machine’s lifespan. Often, the electrical energy expenses associated with the motor will surpass the initial motor cost, particularly for machines expected to operate nearly continuously, 24/7.

Servo motors are usually more efficient than induction motors. This holds true, especially within the lower power range, but remains valid even for larger motor sizes. Even a couple of percentage points of efficiency improvement can make a big difference in the lifetime operating cost of the machine. Once again, it’s worth noting that PM servo motors offer significant cost savings in operational expenses for applications like extrusion, presses, and large spindle motors.

Contact KEB for Large Power Servo Motors

Machine builders are defining ways to set their machines apart from the competition. One effective strategy for achieving this differentiation is transitioning from induction motor to servo motor technology. This shift brings about notable enhancements in various aspects, including increased production output, improved final product quality, reduced machine size, and lower operational expenses attributed to enhanced efficiency and improved intellectual property (IP) protection.

The cost difference between induction motors and servo motors has narrowed over the years, making it worthwhile to reevaluate their suitability for all applications, including large-scale power machinery.

Contact a KEB application engineer to discuss if KEB large servo motors are a good choice for your machinery.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.