Artificial intelligence and the future industrial job field

The notion that developing efficiency in the way we work will destroy the future job market is not new. Articles and editorials currently making the rounds show a range of reactions to how robots and artificial intelligence will affect the workforce.

The hashtag #RobotsDontKillJobs was rising on LinkedIn recently, alongside the publication of this article by Quartz.com: Germany has way more industrial robots than the US, but they haven’t caused job losses. With Germany being a leader in manufacturing, it’s no wonder people are looking to their experiences to learn more about how robots are integrating into the landscape. And the results show that over the last 20 years they’ve integrated extremely well, increasing productivity and profitability. During that same time frame Germany saw little to no change in employment statistics.

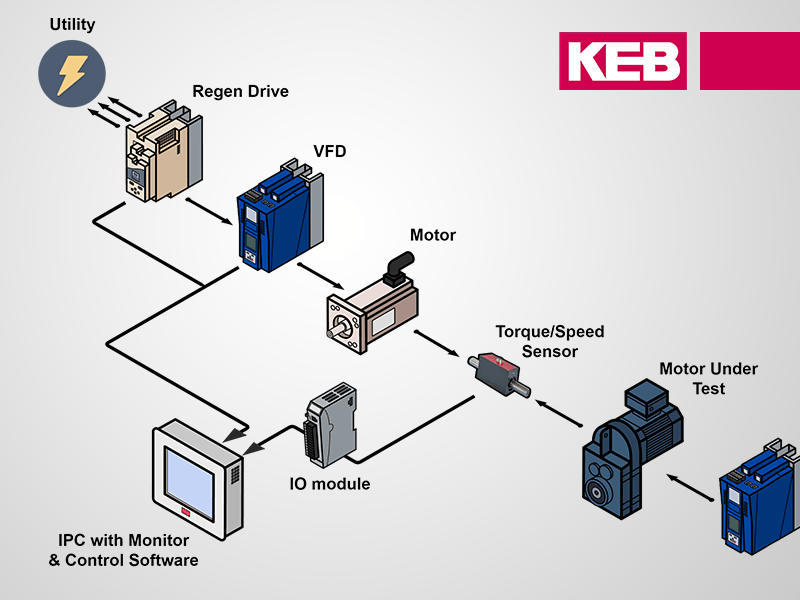

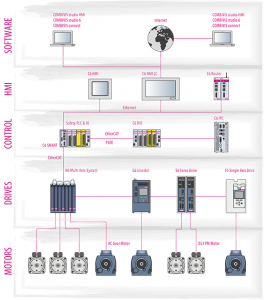

This type of automation – what we like to call “cobots” – where robots work with people in the highly-skilled areas of the manufacturing floor is where KEB products shine. The C6 line of automation tools was created to seamlessly fit into an existing installation so the humans and robots can keep the conversation flowing freely. Products like the C6 Industrial VPN Router for connecting to the production floor, our range of EtherCAT industrial PCs for automation and maintenance and HMI for visualization and control. KEB Profinet servo drives and EtherNet/IP VFDs control various motor technologies. When good communication happens, work is done faster and with more efficiency.

There is, of course, the flip side of the story. On that same trending hashtag, I came across this article from Futurism.com: The Reports Are In: AI and Robots Will Significantly Threaten Jobs in 5 Years. Wait… I thought our jobs were safe from the robots? If we take a look at the kind of work that can be automated, it’s mainly things that can be done by less-skilled hands. Entry-level work is starting to disappear from job postings as these tasks are falling to robots. Workers in positions that require a higher amount of skill and experience seem to be safe from the robot takeover, and in fact are starting to see more job security according to the Quartz.com article, but younger workers aren’t able to get in on the ground level of manufacturing any more, and those with years of experience in the less-skilled tasks have seen a big drop in job security.

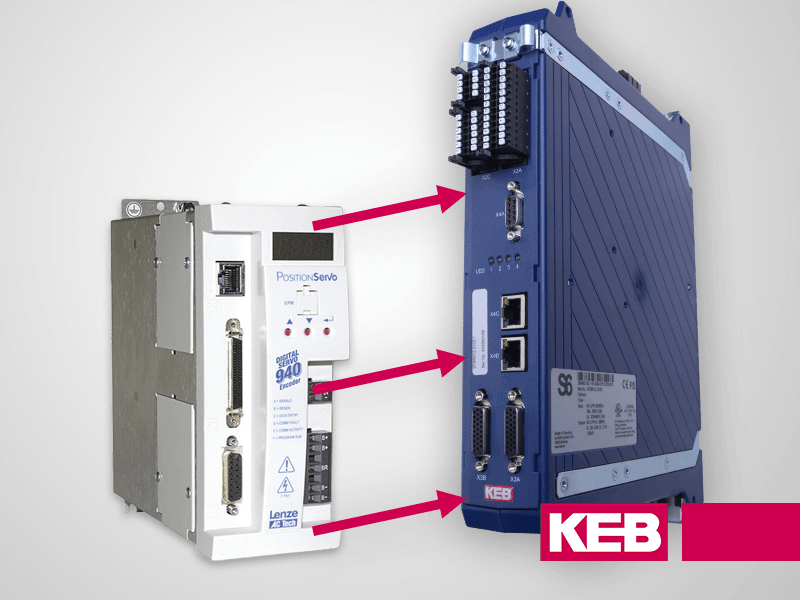

When it comes to designing the tools for modern industrial settings KEB prefers to build systems unique to each problem to be solved, rather than selling individual products. That’s why we’ve engineered a wide variety of options into the brakes, drives, and motors available. In this way we can better assist our customers in designing an automated workflow even if they already have robots at work. KEB robotic clutches and brakes are perfect for applications that require highly precise movements.

Did the digital camera kill Kodachrome film, and in turn has the smartphone caused digital cameras to fall out of favor? Is it Amazon’s fault that Sears is closing stores all over the country? Are millennials killing … well, everything? Probably. Will robots take over someone’s job? Of course they will. The job market of our parents is not the same as the one we came into, and when our children or grandchildren look for their first jobs it will certainly be changed again. And in the end, if Steve Wozniak isn’t worried about robots then we’ll probably be OK.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.