How a 3 Phase AC Induction Motor Works

Learn the basics of a 3-phase AC induction motor, one of today’s most common types of industrial electric motors.

This overview will explain what 3-phase power is, how Faraday’s law works, understand the main components of an induction motor, and the effect of the number of stator poles on the rated speed and torque of a motor.

Watch the video below for an overview of 3-phase AC induction motors.

What is 3 Phase Power?

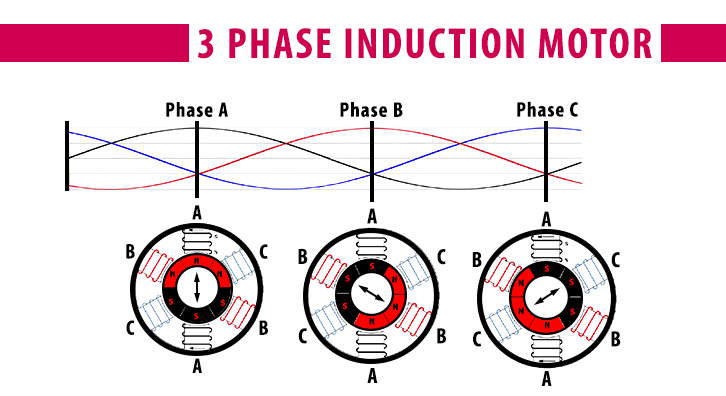

The first concept to understand about a 3-phase induction motor is the first part of its name – three-phase power.

A single-phase power supply uses two wires to provide a sinusoidal voltage. In a three-phase system, three wires are used to provide the same sinusoidal voltage, but each phase is shifted by 120°.

If you were to add up the voltage of each phase at any point in time, the sum would be constant. Single-phase power is fine for residential or other low-power applications, but three-phase power is typically required for industrial or higher-power applications.

It can transmit three times as much power while only using 1.5 times as much wire, and this makes for a more efficient and economical power supply.

Faraday’s Law

Another underlying principle of AC induction motors comes from Faraday’s Law.

The British scientist, Michael Faraday, discovered that a changing magnetic field can induce a current, and conversely, a current can induce a magnetic field.

Using the right-hand rule, you can predict the direction of the magnetic field. To do so, imagine grabbing a straight wire with your thumb pointing toward the current, and your fingers would wrap around in the direction of the magnetic flux lines.

The squirrel cage design is the most common type of induction motor because they are self-starting, reliable, and economical.

In this design, the rotor looks similar to a hamster wheel or ‘squirrel cage,’ thus the name. The rotor consists of an outer cylinder of metal bars shorted on the ends, and the interior consists of the shaft and a solid steel-lined core.

Parts of an Induction Motor

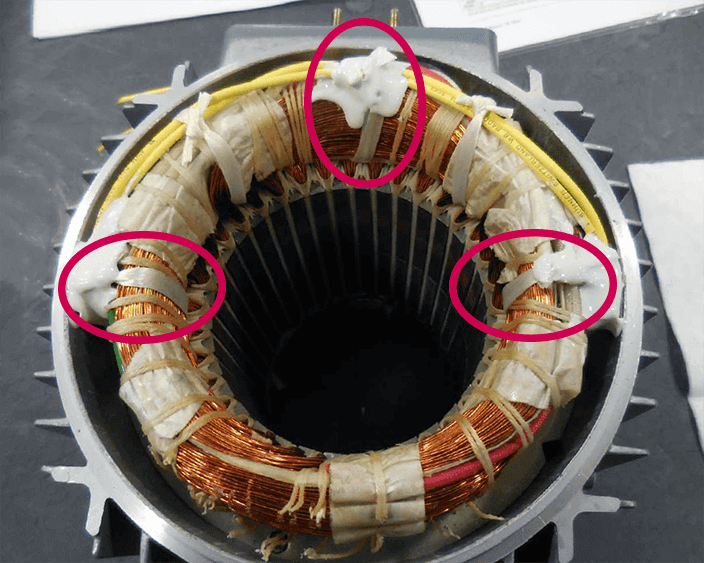

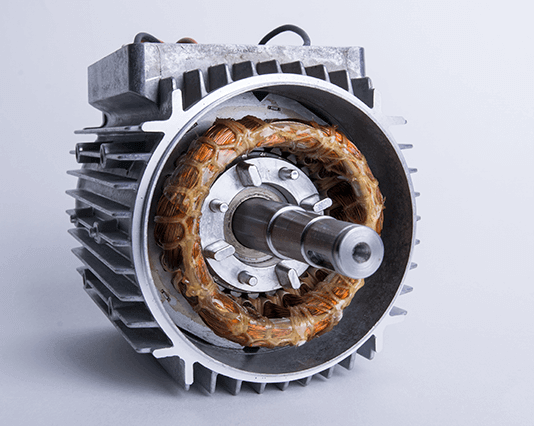

Two main components compose an induction or asynchronous motor: the stator and the rotor. The stator consists of the outer windings or magnets and is stationary. The stator is stationary. For the rotor, the inner core is what actually rotates in the motor, making the rotor rotate.

The squirrel cage design is the most common type of induction motor because they are self-starting, reliable, and economical. In this design, the rotor looks similar to a hamster wheel or ‘squirrel cage’, thus the name. The rotor consists of an outer cylinder of metal bars that are shorted on the ends. The interior consists of the shaft and a solid core built of steel laminations.

How it works

A current is applied across the stator to achieve torque at the motor shaft. This creates a rotating magnetic field, inducing a current in the rotor.

Because of this induced current, the rotor also creates a magnetic field and starts to follow the stator due to magnetic attraction. The rotor will turn slower than the stator field, and this is referred to as ‘slip.’

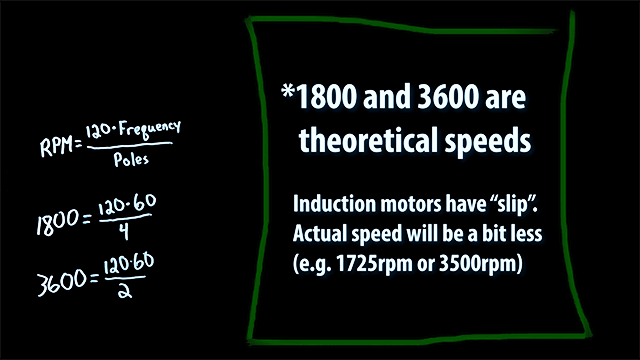

If the rotor were to turn at the same speed as the stator, no current would be induced, and thus no torque. The difference in speed ranges from 0.5 to 5%, depending on the motor winding.

Windings and Poles

Three-phase motors are available in configurations of 2, 4, 6, 8, and up poles.

The number of poles in the windings defines the motor’s ideal speed. A motor with more poles will have a slower rated speed but a higher-rated torque.

Because of this, high pole motors are sometimes referred to as torque motors and can be used to replace a motor using a gearbox. The ideal relationship between the number of poles, frequency, and speed is defined by the following:

Advantages of Induction Motors

Induction motors offer many advantages, including reduced upfront and maintenance costs.

Because of their basic, economical design, induction machines usually cost less than synchronous and dc motors. This makes them ideal for industrial, fixed-speed applications like wind power and wind turbine generators.

The sheer simplicity of induction motors also makes maintenance easier and less frequent, decreasing operating costs over time. This cost efficiency gives induction machines a significant edge over synchronous and dc motors, which feature many additional components, like slip rings, commutators, and brushes.

Durability is another strength of induction motors. These rugged machines can run for several years with little attention and maintenance, even in demanding environments.

The absence of brushes (and sparks) allows induction motors to operate safely in explosive or other environmental conditions, creating a flexible solution for Oil & Gas, material handling, and more.

3 phase induction motors bear unique advantages as well, including self-starting torque. This feature eliminates the need for starting capacitors, typically required for a single-phase motor.

3 phase machines also deliver exceptional speed regulation and overload capacity, making them viable for various applications.

Applications for 3 Phase AC Induction Motors

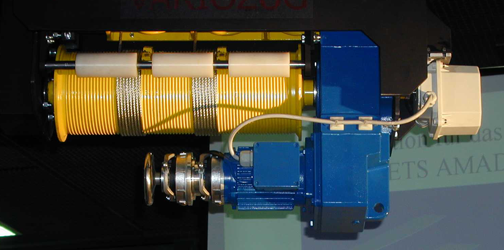

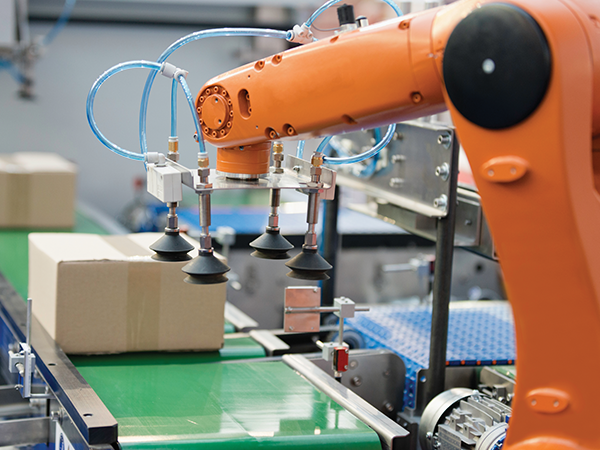

By converting electrical energy into mechanical energy, 3-phase AC induction motors can drive various components — from pumps and fans to compressors and conveyors — in industrial or higher-power applications.

3 phase AC induction motors represent a premium, low-cost choice for simple, single-speed applications. This includes rotary turntables, material handling conveyors, industrial fans, and other straightforward systems.

3 phase induction motors are also well suited for eMobility applications, including commercial electric and hybrid vehicles.

Induction motors minimize costs and potential points of failure across mining and farming equipment, trucks, and school buses while optimizing motor control performance, providing a comprehensive solution for eMobility machine builders.

The 3 Phase Induction Motor Components

The stator and rotor comprise the 3-phase AC induction motors.

During operation, a current is applied through the stator, which induces a magnetic field and leads to the rotation of the rotor. The rotational speed of the shaft and the applied torque depends on the operating frequency and the number of pole pairs in the motor’s windings.

If you are interested in our product line of induction motors, gearmotors, or even servo motors, contact a KEB application engineer with the contact form below.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.