Better Machine Design Starts with Motor Technology

Machine design is a linchpin for mechanical industries, from Aerospace and Medical to Emobility. This process ultimately determines manufacturing costs and profits for the product, setting the stage for its success or failure. As such, intelligent machine design requires a careful balance of innovation and practicality.

New machines must serve the many needs of their market and end users, from efficiency to form factor, while keeping costs as low as possible. And one of the best ways to marry these design goals is to invest in superior motor technology.

Here’s an overview of how leading motor technologies help drive performance, reliability, and lower costs for machine builders:

Machine Motors: Choosing the Right Tool for the Job

Over the years, a big change in machine design has been the migration from DC motors to AC motors. Unlike the former, AC motors do not rely on soft contacts (or brushes) that wear down and must be replaced over time. AC induction, linear, and synchronous motors offer exceptional durability for longer lifespans—and can be outfitted with variable-frequency drives (VFDs) to optimize motor speed and torque. This rounds back to a core design tenet: choosing the best motor for the machine.

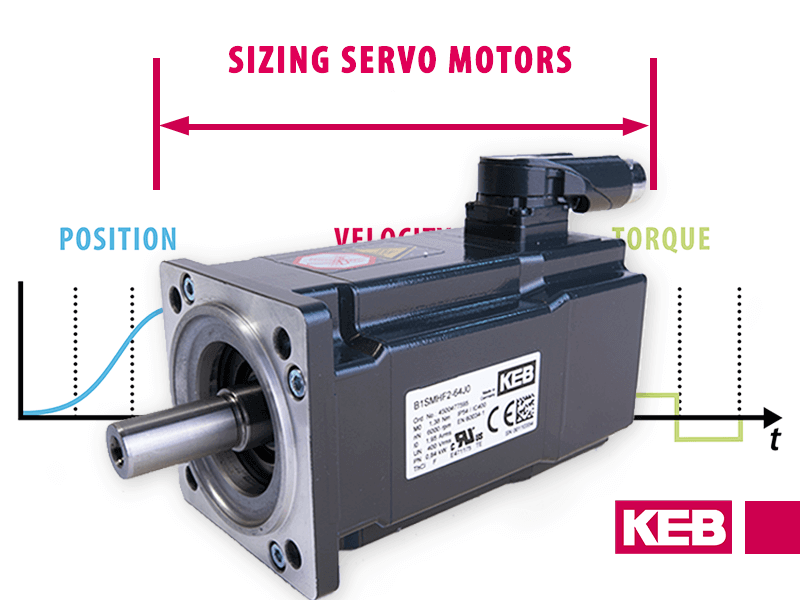

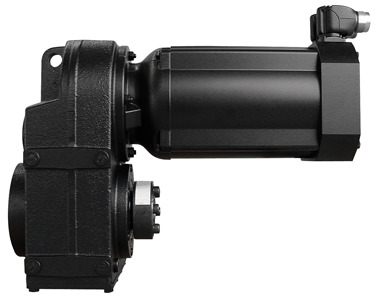

An ideal machine motor gives builders maximum design flexibility, while delivering dependable performance and longevity across applications. In some cases, this might mean using a variety of different motor types. For example, it’s best to use stepper motors on small axes that do not require precise positioning or accuracy. In contrast, high-precision applications (like robotics) may require a servo motor.

Motor Technology for Machine Performance

As the beating heart of the machine, motors play an essential role in a product’s overall performance. This is why machine builders invest in AC PM Servo motors. These solutions have low intertias and are ideal for dynamic applications, where acceleration and deceleration rates are frequent. AC PM Servo motors can also leverage various feedback devices, which can be used to continuously read for and correct errors in motor velocity, torque, and position. Consequently, these servo motors offer great performance through pinpoint speed and torque regulation.

AC PM Servo motors offer a few major performance advantages for machine builders, including the following:

- High output power

- Dependable torque, even at high speeds

- Quiet operation

- Excellent acceleration

- Good torque-to-inertia ratio

Motors for Compact Machines

More compact machines require smaller motors that do not sacrifice results. This is why machine builders invest in AC PM Servo motors, which are more compact than their induction motor counterparts. Using liquid-cooled motors allows more power output, enabling optimal performance in small-sized machines.

We see huge demand for this motor technology solution in Plastics machinery. Extruders and injection molding machines used throughout this industry require compact, high-efficiency motors for speeding up workflow and volume.

Motor Cooling Technology

Excessive heat within a machine will lead to failure, which adversely affects throughput and production. To combat this problem, machine builders utilize liquid cooling—a better means to cool motors that becomes even more important at larger power levels. Liquid-cooled VFDs pair perfectly with water-cooled motors for more stable product performance.

Several sectors have growing demand for this liquid-cooled technology, including Plastics (extruders and injection molding machines), as well as mobile machinery and recycling machines.

Motors for Machine Efficiency

Did you know that industrial electric motors account for the largest end use of electricity in the United States? Over its entire lifespan, an industrial machine can accrue massive energy expenses, increasing its total operating costs. Thankfully, machine builders can address this issue by investing in more efficient motor technologies that mitigate energy use.

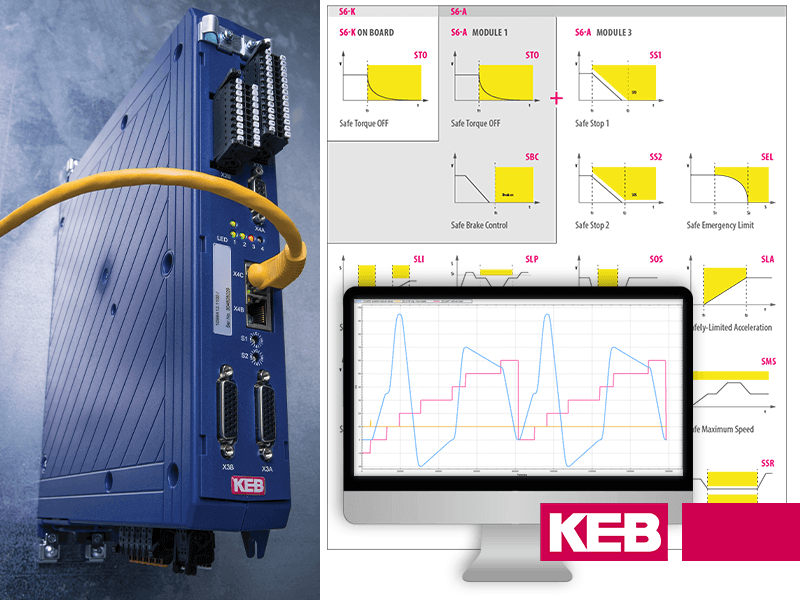

The higher the hp (horsepower), the more important energy efficiency becomes for a machine. The same applies to the machine’s duty—or the length of time it stays in operation. Products running 24/7 should use the most energy-efficient motor possible to reduce operating costs over time. Controlling the motor (e.g., reducing speed) also provides an effective way to cut energy costs, which is where VFDs come in handy. KEB variable-frequency drives can help adjust motor speed to save energy and maximize system efficiency.

Motor Longevity & Reliability

Machine builders prioritize the longevity of motors to ensure their products run reliability over an extended lifespan. For this benefit, induction motors have historically been preferred—namely because they are extremely reliable and can be run off the line. However, newer motor technologies like Synchronous Reluctance motors are bucking this trend.

According to ABB, Synchronous Reluctance motors pair the performance of a permanent magnet motor with the simplicity of an induction motor. These motors offer better efficiencies and results compared to conventional induction motors, while still being straightforward in design, easy to maintain, and highly reliable.

If you’d like to see this powerful solution in action, then check out this video on the Synchronous Reluctance motor from KEB!

Rethink Machine Performance with KEB Drives

Contact a KEB applications engineer today to learn more about how you can leverage motor technology—and industry-leading VFDs—to improve machine design and performance.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.