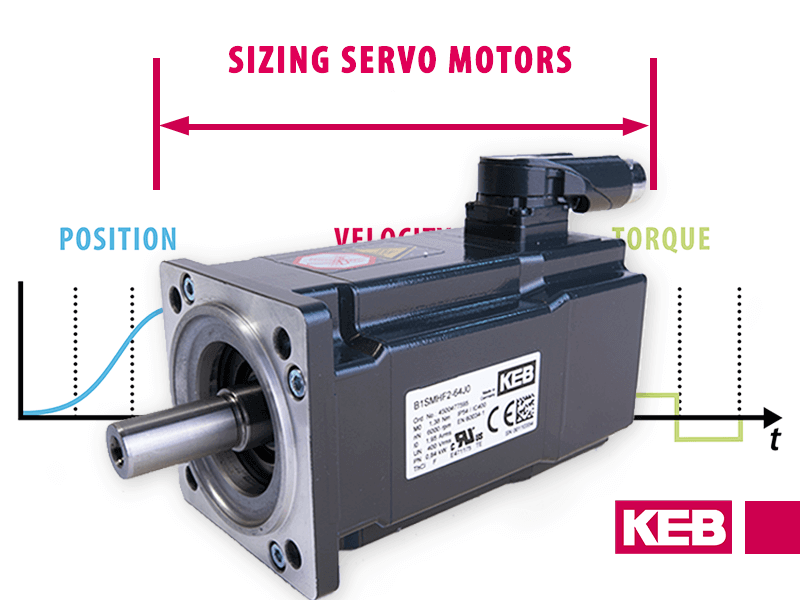

Servo motors are powerful, compact solutions used across many industrial applications. These lightweight motors produce significantly more torque than induction motors of similar physical size, making them ideal for applications with strict weight or space limitations.

The lifespan of a servo motor depends on multiple factors, from environmental conditions to application parameters. Most OEMs will list 20,000 to 30,000 working hours as a general range, but this will vary based on how the machine is set up, maintained, and operated.

Let’s review these elements in more detail to help you decide whether a servo motor is the right choice for your application—and understand how to maximize its operating life for your unique needs.

Why Do Servo Motors Fail?

Like any machine, components of a servo motor will break down with time and frequent use. Any contact or friction between moving parts eventually leads to wear—and this process accelerates when the motor is incorrectly used and maintained. Common factors affecting servo motor lifespan include the following:

Bearing Failure

According to the Department of Energy, bearing failures are responsible for almost two-thirds of all motor failures. Repeated use of a servo motor causes its bearings to wear out and become misaligned, decreasing the motor’s overall lifespan.

In particular, engineers will want to pay attention to the overhanging load ratings when designing a machine. Exceeding the published manufacturer ratings will accelerate bearing failure.

Overheating & Contamination

Higher temperatures drastically affect motor life and performance. Poor ventilation, high environmental temperatures, and even dirt or contamination will cause a servo motor to overheat, leading to thermal damage and failure.

Nearly all servo motors will be equipped with motor temperature sensors. These sensors should be used to detect abnormally high temperatures and respond accordingly to avoid motor failure.

Bad Winding & Cables

A servo motor’s windings and system feedback cables will degrade over time, resulting in performance issues and voltage spikes. Application factors like long motor runs can exacerbate these issues.

Improper Maintenance

This is a leading cause of servo motor failure—and a key step you should look at to improve motor lifespan. Most of the issues above can be controlled or prevented outright through intelligent maintenance. This includes basic things like maintaining proper belt tension.

How Long Do Servo Motors Last?

Leading OEMs like Siemens and Allen Bradley typically list the lifespan of servo motor bearings for 20,000 to 30,000 hours. However, depending on your application and working conditions, your servo motor may last for decades or less than a year. Why? Because some environmental factors and parameters are so harsh on the motor that it fails much earlier than expected.

Factors Affecting Servo Motor Lifespan

Motor Speed

Speed determines how much input power is needed to sustain the servo motor. A servo motor running at high speeds will require more motor rotations, resulting in increased wear on the system’s bearings and components. Motors operating at lower speeds produce less shock and vibration stress, which translates to a longer machine lifespan.

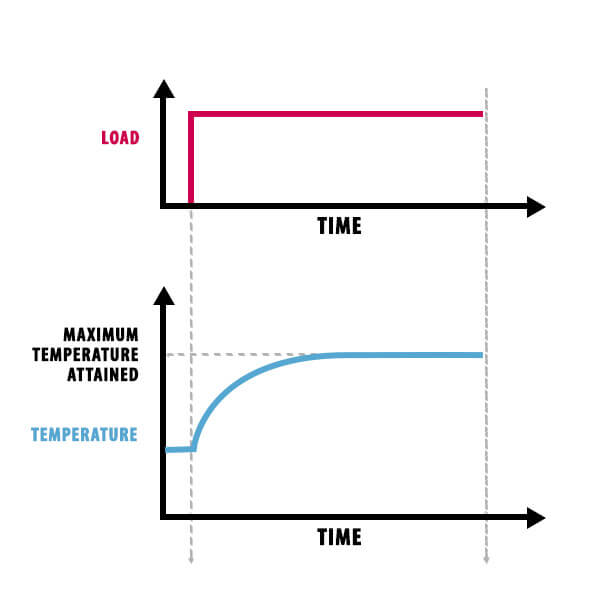

Motor Duty Cycles

Higher motor duty cycles result in increased or even constant run time, shortening the total lifespan of the motor. Servo motors on continuous duty (S1) are expected to run steadily for huge stretches of time, exposing them to more stress and natural wear.

Environmental Conditions

Factors like uncontrolled moisture, oil, grease, and high ambient temperatures adversely affect motor performance and operating life. Maintaining a clean, well-ventilated operating space is the best way to manage these threats.

How to Improve Servo Motor Lifespan

Choosing the Right Servo Motor for Your Application

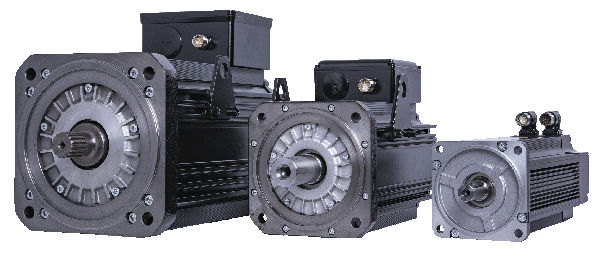

There are many types of servo motors, with some built for specific duty cycles and industrial applications. By understanding the demands of your application, you can invest in the right servo motor for those needs and constraints. A purpose-built motor will enable better performance across your operations while improving the system’s lifespan.

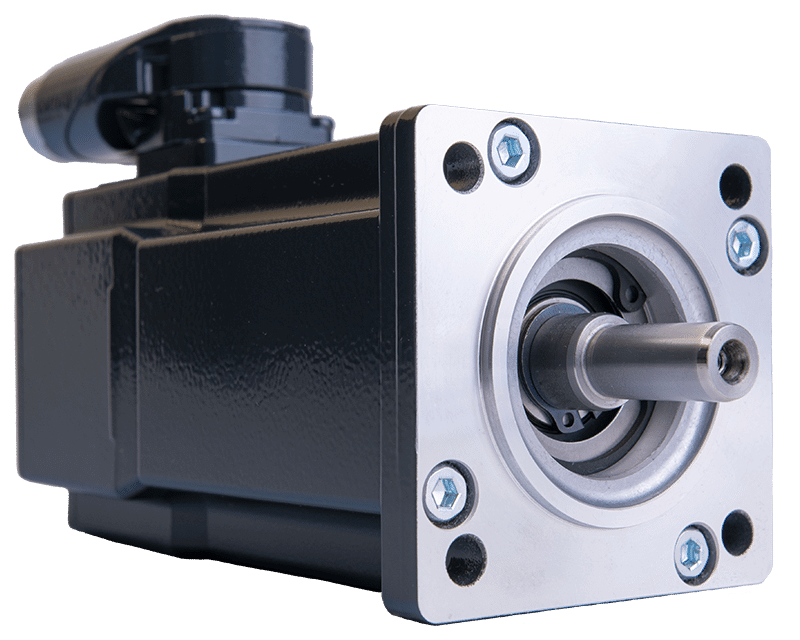

For example, KEB AC synchronous servo motors can be configured with a range of feedback and brake options, as well as rotatable connectors for greater flexibility. These versatile DL3 servo motors are offered with low and medium inertia models for dynamic, efficient control—and are suited for even the most demanding positioning and cycling applications.

Servo Motor Setup and Upkeep

Once you’ve selected a servo motor, it’s crucial to make sure the solution is correctly installed and well maintained. Improper installation causes problems affecting the system’s lifespan, from misaligned motor bearings to suboptimal operating environments. This extends to selecting the correct feedback cables for the servo motor system. Without quality cabling, a high-performance servo motor will run at a fraction of its potential and hamper productivity.

Even a perfectly installed servo motor will need regular upkeep to maintain reliable output. This is where predictive maintenance can help; it empowers your technicians to anticipate future motor problems and proactively fix them. Predictive maintenance reduces disruption, prevents costly downtime, and maximizes the operating life of your servo motors.

Advance Your Application with KEB Servo Motors

KEB offers a full portfolio of innovative control and automation solutions to meet your unique needs, including purpose-built motors. To learn more about our servo motor technology, and how it can help take your industrial application to the next level, contact a KEB Application Engineer today.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.