KEB America Showcases Servo Pump Control Solutions at NPE 2024

High-torque servo motors and liquid-cooled VFDs improve product quality and throughput in plastics injection molding and extrusion machines

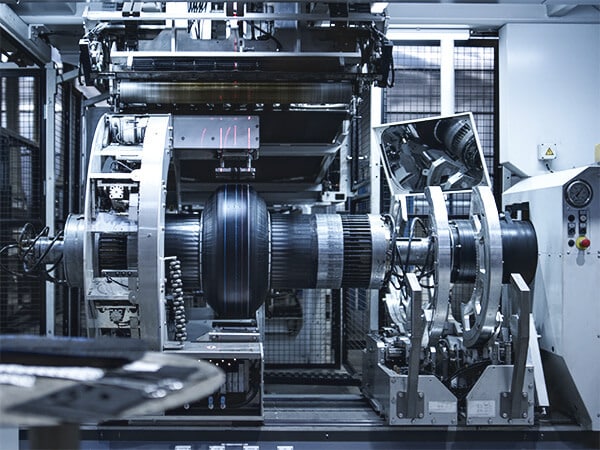

Orlando, Florida, May 6, 2024 – KEB America, Inc., a subsidiary of KEB Automation KG and the North American provider of motion control and industrial automation solutions, unveils its innovative plastics machinery solutions at NPE 2024: The Plastics Show in Orlando, Florida. KEB’s high-torque servo motors, paired with large-power variable frequency drives (VFDs) and intuitive programming software, empower plastics machinery manufacturers to achieve unparalleled safety, efficiency, and reliability.

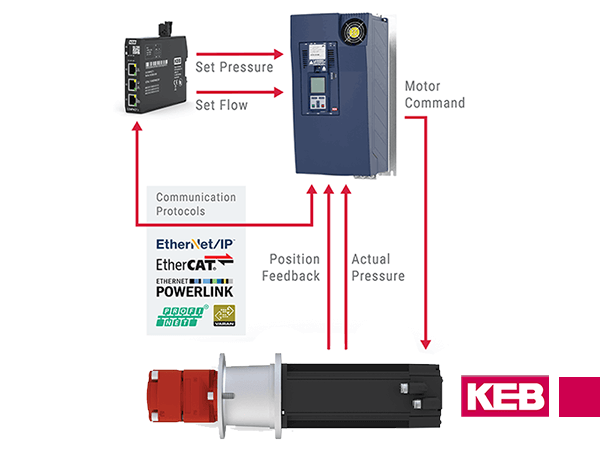

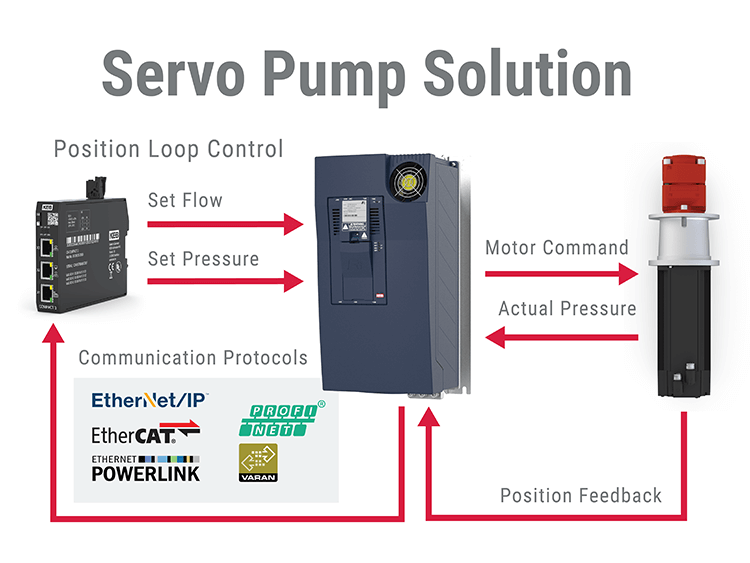

The KEB servo pump control solution is an advanced system comprising high-torque servo motors, large-power VFDs, and programming software that regulates the pressure and flow of hydraulic fluid in plastic injection molding machines. The solution is equipped with servo pump real-time control, allowing users to regulate a system’s flow and/or pressure directly from the motor without using valves.

“Compared to traditional hydraulic pump motor solutions, KEB offers a simpler servo pump control system for plastics molding and press machines,” said Jonathan Bullick, National Sales Manager at KEB America. “Our solution reduces noise emissions, minimizes heat input into the hydraulic system, decreases hydraulic power loss, extends components’ service life, and users can achieve energy savings of up to 70%.”

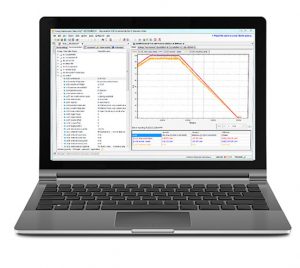

In addition to its servo pump control, KEB America is also demonstrating solutions for a wide range of plastic machinery. These solutions include DL4 servo motors, F6 VFDs, and Combivis® 6 software. The intuitive software features programming wizards to simplify motor startup, communication setup, and protection settings. The software’s 16-channel scope traces facilitate tuning and system optimization, enabling quick integration and enhanced performance.

KEB’s VFD lineup for plastics machinery comprises the S6 and F6 drives, which are capable of meeting diverse power requirements ranging from 0.5 kW to 900 kW. These drives support leading industrial protocols, including EtherNet/IP™, EtherCAT, POWERLINK, PROFINET, and VARAN. The F6 drives offer air-cooled and liquid-cooled options and incorporate advanced sensorless control algorithms, delivering consistent performance and durability without needing motor encoders.

The DL4 servo motor series delivers exceptional torque of up to 520 Nm (880 Nm peak) and a rated motor speed of up to 3,000 rpm (peak 6,000 rpm). KEB’s motors come in three UL-certified frame sizes and four stack lengths. They operate at a nominal voltage of 400V. The DL4 permanent magnet synchronous servo motors are ideal for extrusion, thermoforming, and other plastics-related machinery, as they offer dynamic performance in these applications.

Visit KEB America at booth S30089 in South Hall, Level 1 at NPE 2024 to explore how servo pump technology and motion control products can optimize a plastics machine’s processing operations.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.