The F5 inverter from KEB America has been a popular drive for many years due to its flexible design, range of available sizes, and lengthy list of options, including communication protocols. Now with the introduction of our F6 drive, KEB will continue to offer flexible, powerful, and reliable products for machine builders who use a long list of different communication protocols.

One of these protocols is Modbus®, and the most commonly used version is Modbus RTU. This type of protocol is often seen in industrial automation settings because it’s easy to integrate and use, which is why KEB has made it part of the modular communication features of the F5 and F6 VFDs.

Related Article: Modbus TCP Startup Procedure

Modbus Overview

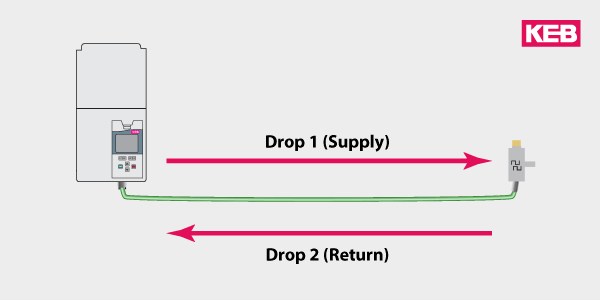

Modbus RTU uses the RS-485 serial port to transmit communication between machines. Information is sent between a single Master device and the Slave devices as simple,16-bit messages.

When using Modbus RTU data is stored on the Slave devices in four tables – two for coils (on/off values) and two for registers (numerical values).

Customers using Modbus RTU can expect fast and reliable data transmission because of the compact binary messages and CRC error-check mechanisms.

F5 and F6 – Scalable Drive Platforms

The full family of F5 and F6 drives have been designed for use in many different industries across a global platform. They’re available in 230, 480, and 690 VAC classes, with scalable sizes from 1 Hp to 1000 Hp. An optional integrated braking transistor can be added for hoisting and regenerative applications, which saves on cabinet space as a separate unit is not required.

Open Loop, Closed Loop, and SCLTM

When it comes to machine control, the F5 and F6 have options for open loop, closed loop, or KEB’s unique SCL™ technology. With the SCL control algorithm precise speed and torque control is possible without the use of encoder feedback, and in some cases positioning control can be achieved without an encoder.

Internal positioning functionality is built into F5 and F6 drives for easy coordinated movements over the drive communication bus. They can run both induction and servo motors. These options, along with the communication protocols available, are why the F5 and F6 drives are a perfect choice for the system integrator who works with many brands of PLCs and integrated control.

Let us help with your next Modbus RTU Application

KEB has been designing and manufacturing inverters for over 30 years. If you have a question about which F5 or F6 drive options best suit your application, contact KEB today.

Modbus® is a registered trademark of Schneider Electric, licensed to the Modbus Organization, Inc.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.