Selco Elevators Ltd is an independent elevator manufacturer with over 170 elevator specialists in Toronto, Canada. For 30 years, the company custom-designs, installs, and services luxury elevators for multi-million dollar residences, commercial buildings, and hotels in the Greater Toronto Area.

Since 2012, Selco relies on KEB products in high-speed and high-usage elevators projects. The KEB F5 Drive is widely used in the elevator industry, “Due to its reliability and adjusting qualities,” said Massimo Sciarra, adjuster at Selco Elevators. “It’s a far superior product than what we have used in the past.” Selco adjuster Paul Domingues agrees, “The reliability… it controls the elevator a lot better than some of the other drives [that] I have worked on.”

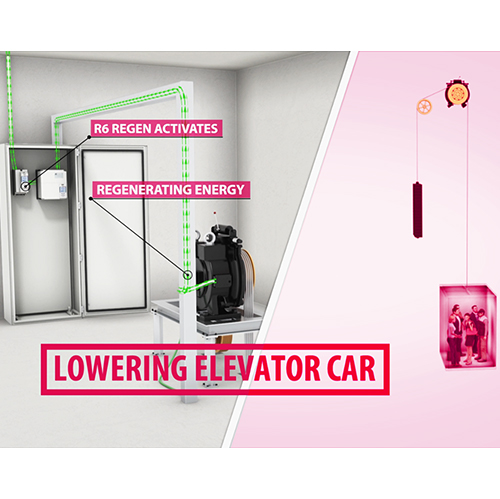

KEB also offers energy-saving, green technology to work harmoniously with the F5 Drive. Its R6 Regen Line Unit regenerates energy to the building power instead of being dissipated as wasted heat in a counterweighted traction elevator. The more frequent and higher elevator usage, the more cost savings for the building owners.

See your potential savings: Elevator Regen Calculator

42 Charles St E High-rise

Located in the heart of Yorkville, the Casa 2 high-rise is a high-end condominium building in Toronto, Canada. Selco was commissioned to install and maintain the four elevators in the 56-story, 500-unit building. They deployed a GAL controller with the KEB F5 Elevator Drive to manage cab speed, ride quality, and performance.

For unit owners, the four elevators are their main mode of transportation from the lobby to their residence and vice versa. Any type of disruption affects the travel experience for a lot of people.

“In any building, the flow of traffic is important,” said Massimo Sciarra. “If we are down to three elevators, it’s a problem, especially during rush hour times. Your reliability is key and crucial for the flow of traffic.”

With speed, reliability, and safety being paramount, Selco turns to trusted KEB drives with GAL controllers to deliver a smooth ride and quick floor-to-floor speed.

Selco Elevators, a Canadian elevator contractor, shares how it’s able to achieve excellent ride performance with KEB drive products.

Ensure A Smooth Ride

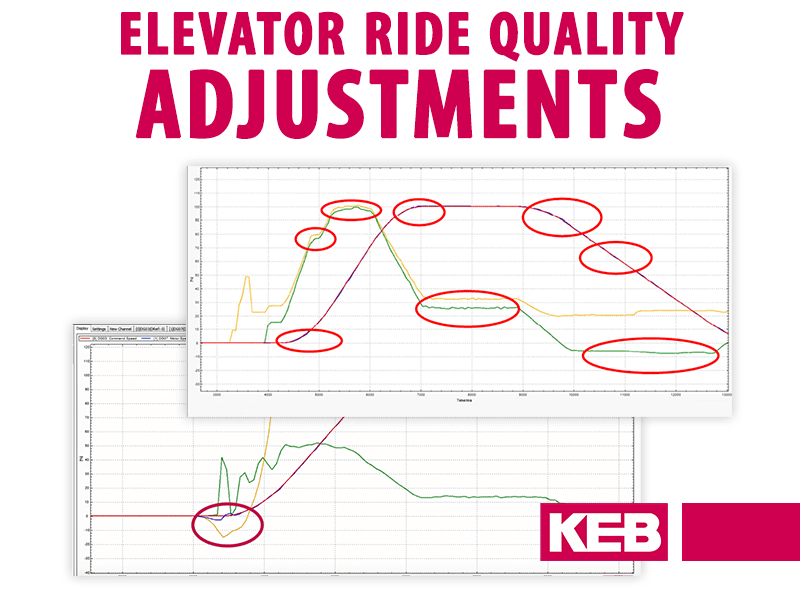

There are a number of factors that contribute to a poor elevator ride experience. This includes wind, push, rails, cable length and stretch, and any type of resonance frequency increases noise and vibration.

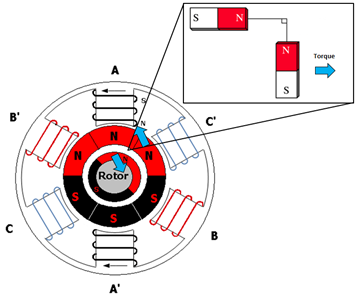

The KEB F5 Drive enables users to fine-tune imperfections out of the (permanent-magnet) PM gearless motor on long-distance runs. Special features like Pre-Torque™ and KEB’s notch filter allow the elevator performance to be dialed in. Massimo Sciarra adds, “You can pretty much tune out certain frequencies that can give you vibrations. It gives you a smooth, clean ride.”

Increase Floor-to-Floor Speed

The Casa 2 elevators operate at speeds of 800 feet per minute. Selco initially established the inertia learns using the regular serial pattern on the GAL controller. “The ride quality was good, but was still lacking that max performance,” said Sciarra.

Selco began to use more of the KEB Drive to compliment the serial communication from the GAL product. “The flight of the car was like a night and day difference,” Sciarra added. “The speeds coming into the floors were cut by about two to three seconds per ride.”

In a 56-story building, shaving the time between floor-to-floor stops helps passengers get to their destination a lot faster.

Quality Products and Exceptional Support

KEB’s industrial automation products are German-engineered and made, assembled, and supported in the United States. KEB manufactures and assembles these products using the highest quality materials at its 150,000 sq. ft. facility in Shakopee, Minnesota. “KEB’s product for high-speed applications is probably one of the best ones that I have seen in the 30 years I have been working,” said Massimo Sciarra.

In addition to quality products, KEB offers customers an experienced team of solution experts for in-person or online consulting, training, and support. Sciarra adds, “Their support is fantastic. They have gone above and beyond helping us to try and make sure that they can solve any of the questions that we can’t answer ourselves. I’ve had their support not just with GAL but other controller manufacturers that had purchased KEB itself.”

A motor learn procedure using a KEB F5 Elevator drive installed with a GAL Galaxy 3 controller at 42 Charles St E High-rise.

Contact KEB

Need assistance with a project or technical support? Fill out the form below to connect with one of our elevator representatives. We are here to help you find the best solution for your business.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.