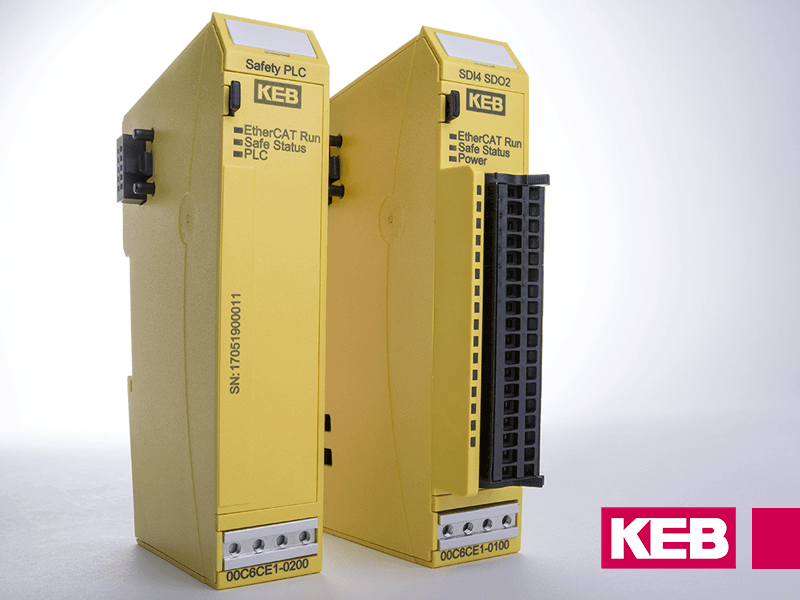

With the development of Safety over EtherCAT (FSoE) in KEB’s Safety PLC and Generation 6 drives, a powerful new tool has been added to the machine builder’s toolkit. A previous FSoE post went into the basics of FSoE. This post will go into more detail on how the advantages of FSoE can be put to use in your next machine design.

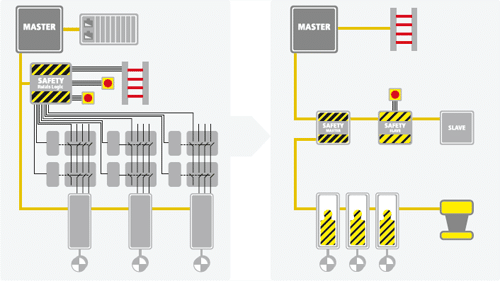

1. Reduced and Simplified Wiring

One simple yet important benefit of FSoE is the reduction of the discrete safety wiring. No longer is it needed to wire all the discrete safety I/O back to the Safety PLC. The reduced wiring benefits become most evident in applications having longer conductor runs and those using many safety devices.

FSoE makes it possible to evaluate discrete safety inputs and even safe encoder signals (position) in the KEB S6 or F6 drives. This information can then be communicated from the drives to the Safety PLC over the SIL3 certified FSoE protocol. Both the safety information and regular machine information can be transferred via a standard Ethernet cable. So the wiring and terminations are quick and easy with little chance of wiring mistakes.

With this simple connection, all safety functionality on the FSoE and standard EtherCAT drive control can be achieved. This allows for a more complex machine safety design without worrying about the cost and time involved with wiring. Now the time of wiring and testing out I/O can be saved or put to better use with more comprehensive machine commissioning.

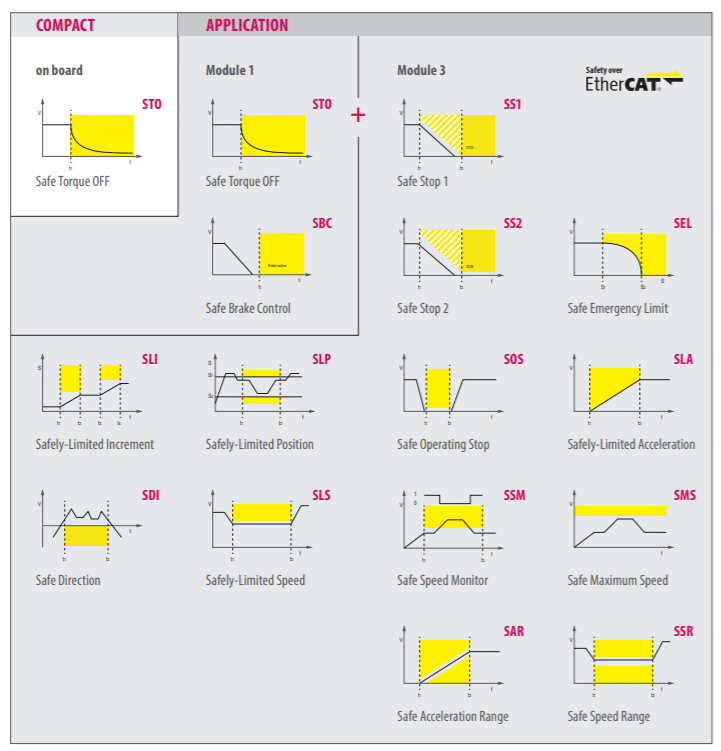

2. Flexibility of Safety Functions

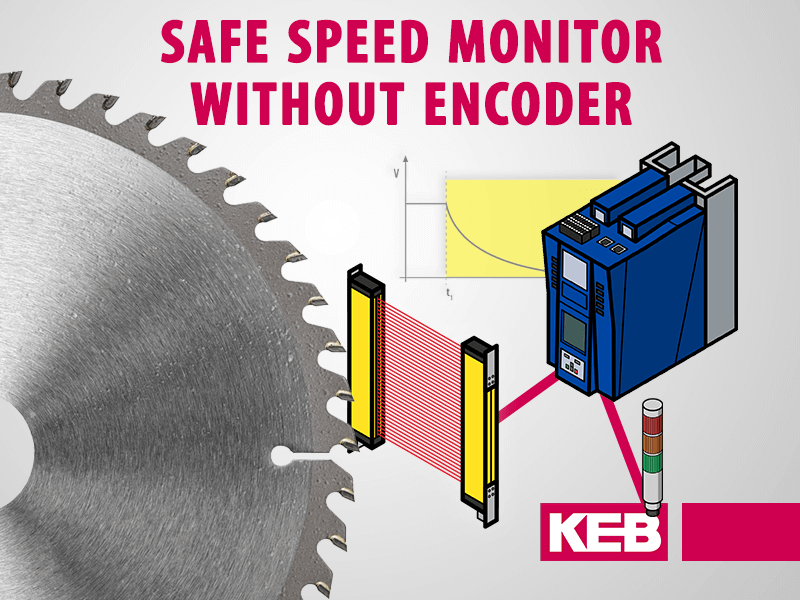

With FSoE, there is also more flexibility in the selected Safe Motion functions available in KEB EtherCAT drives. It is no longer only about implementing the dual-channel STO. KEB drives support a number of Safe Motion functions which offer advanced functionality and handling – these carry a safety certification up to SIL3.

For example, a robotic controller might utilize Safe Acceleration Range to monitor the acceleration rates of the robotic arms. Detecting an abnormal acceleration can provide a quicker error response than waiting to reach a limit switch or torque limit.

In another example, some machines or processes might require that the motor shaft spins in only one direction. Spinning the motor in an unintended direction could cause catastrophic damage to the machine-like damaging a screw or special bearings. A designer might utilize the Safe Direction function to ensure that the motor only rotates in the intended direction.

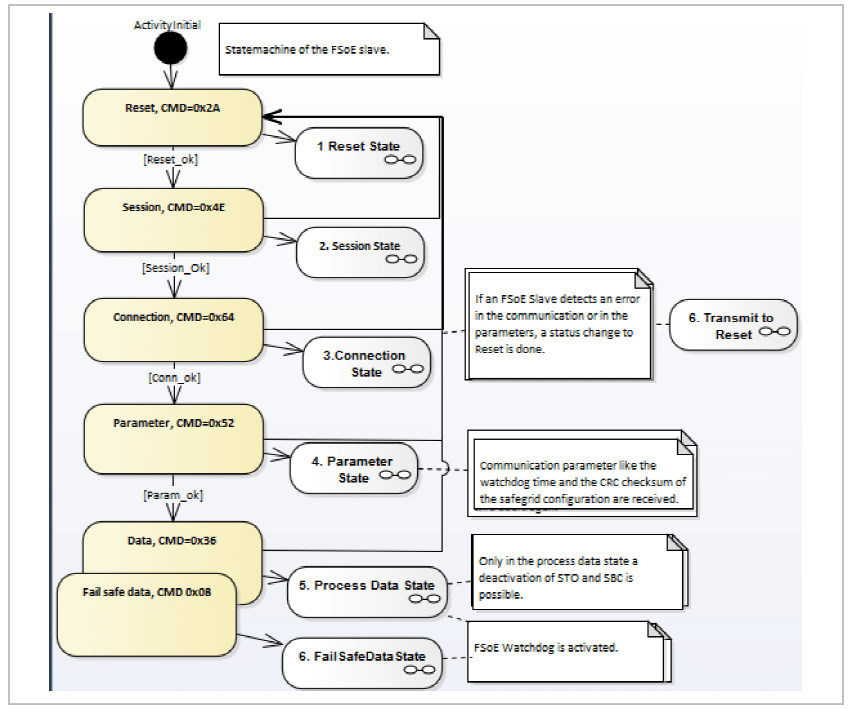

3. Detailed State Machine

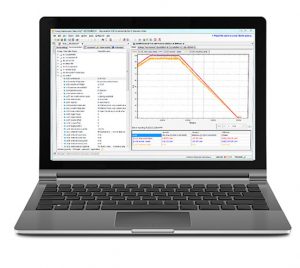

Each FSoE slave device is built on a state machine backbone. Upon startup, the state machine must be incremented sequentially before it is possible to transmit the process data. In combination with the log in KEB’s Combivis Studio 6 programming environment, tracking EtherCAT and FSoE statuses or troubleshooting errors is much simpler.

For example, if an FSoE configuration is used that is dependent on encoder data, such as Safe Limited Speed (SLS), but no encoder has been configured within the drive safety setup, a bus configuration error will display on the log. The state machine utilized by FSoE and the detailed log functionality within Combivis Studio 6 can be a powerful tool in the commissioning of new machines or troubleshooting existing machines with functional safety.

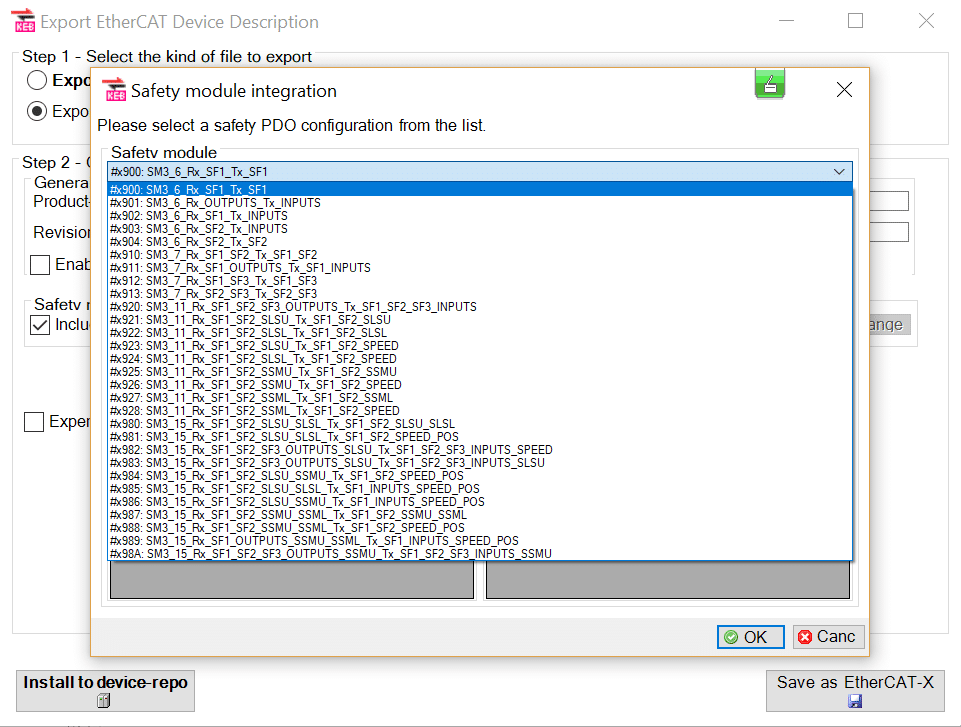

4. Configurable Process Data

Utilizing FSoE and the wizards built into Combivis Studio 6 allows for the simple and easy setup of dozens of different configurations of process data. On the simple side, configurations with six FSoE frame elements can be used to control the safety functionality and to read back the statuses. On the more complex side, configurations with 15 FSoE frame elements can be used to support additional safety functionality. This allows for more flexibility when setting up the FSoE and allows the user to select as many or as few safety functions as needed.

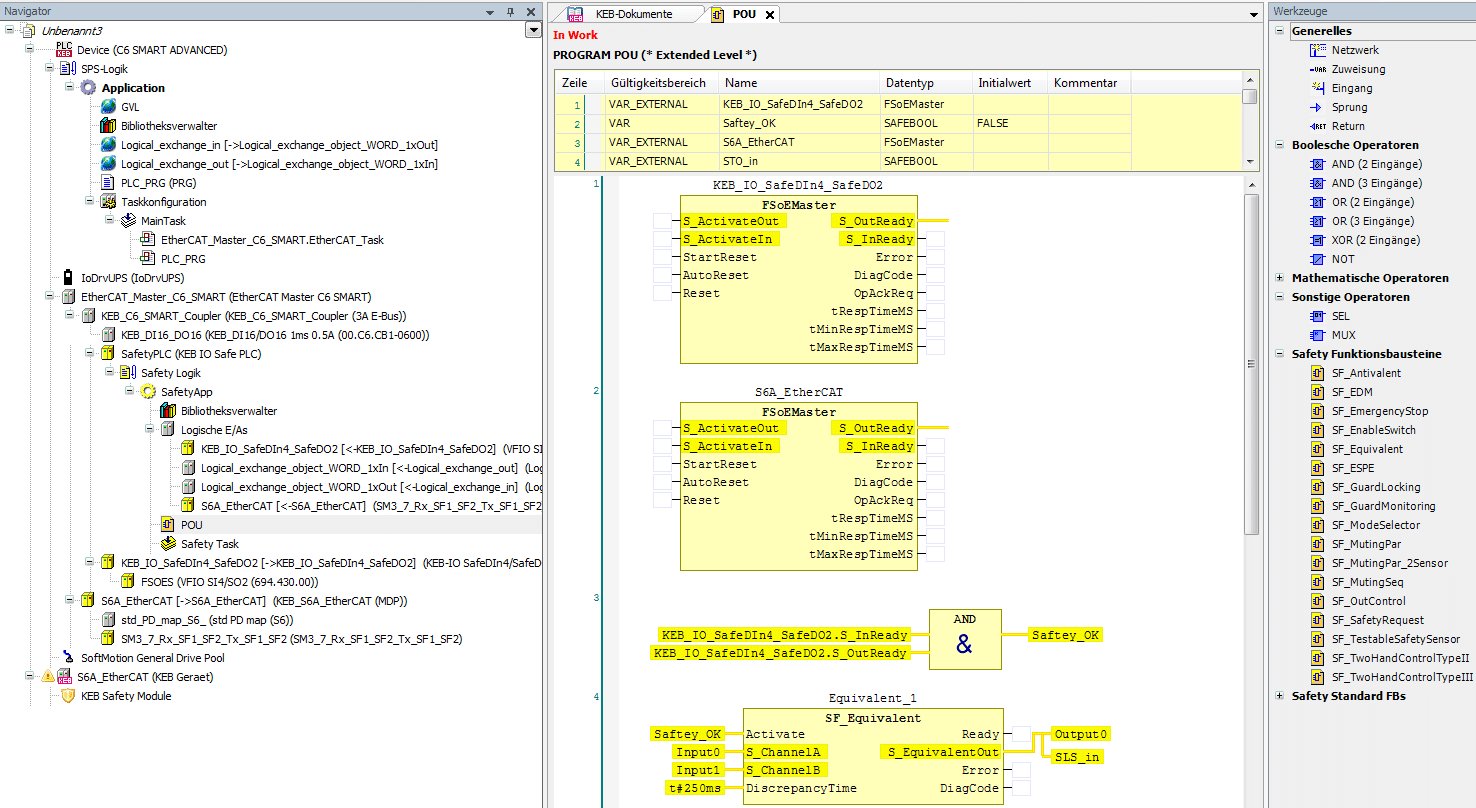

5. Safety Function Blocks

With the number of safety functions available in the S6 and F6 drives that can be transmitted via the process data of FSoE, it could be overwhelming to start the programming of the safety PLC. However, KEB’s Combivis Studio 6 provides pre-certified safety function blocks, according to the PLCopen Safety standard. These prepared function blocks minimize the programming time of the safety PLC to allow for an easy startup while also allowing for more complex programs if needed. Additionally, Combivis Studio 6 clearly identifies safe and unsafe variables – making it clear what variables can and cannot be used with safety function blocks. Utilizing these tools allows for nearly limitless options when programming the safety functionality within FSoE and the safety PLC.

Better Machines with Functional Safety

With the increasing desire and requirement for functional safety in new machine designs, FSoE can be a powerful tool for machine builders. Utilizing KEB’s line of FSoE devices can save time and money in all stages of the machine’s lifespan from design, commissioning, and service.

Interested in how FSoE could be implemented in your application? Contact an Application Engineer at KEB America today!

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.