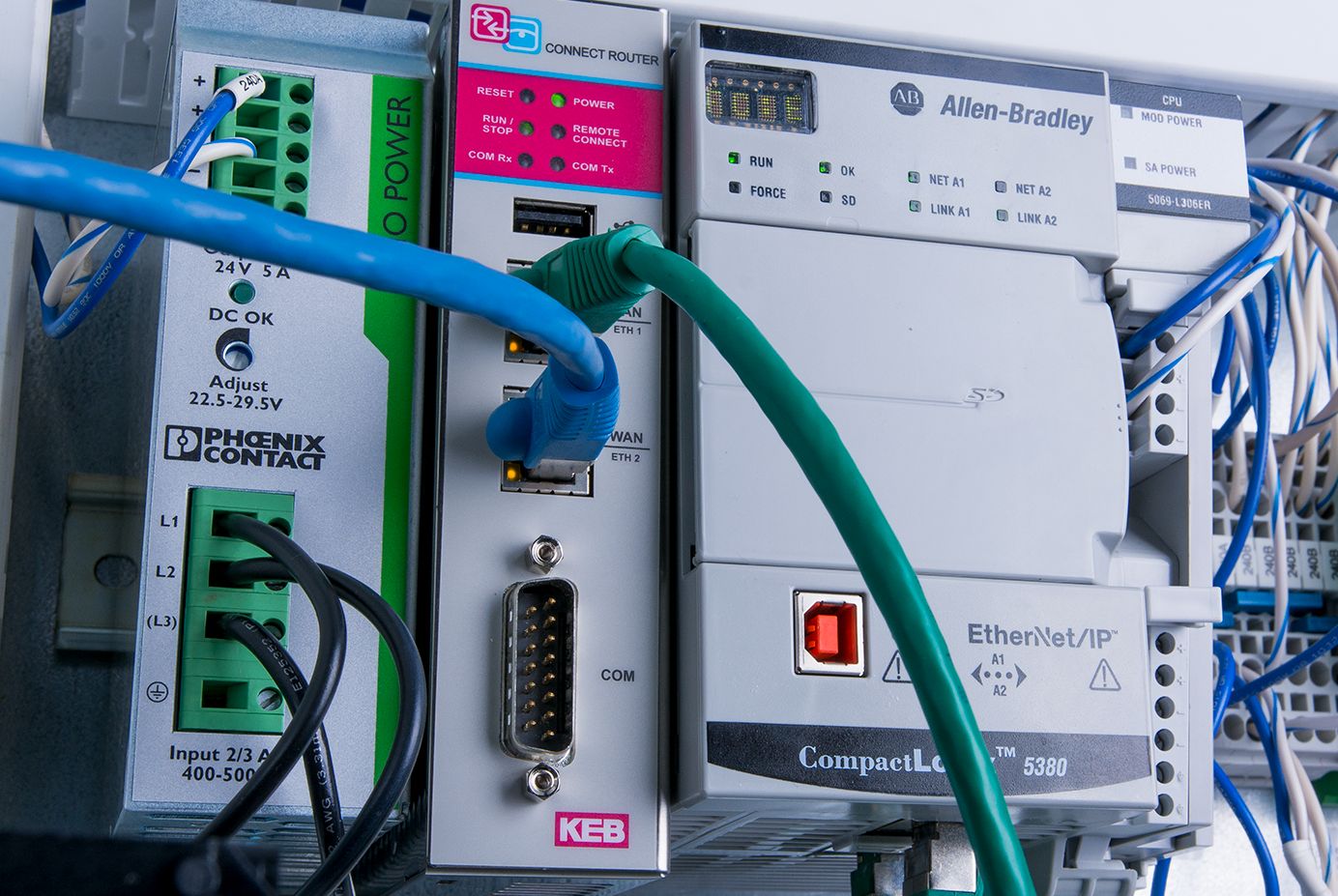

KEB C6 HMI with Allen Bradley PLC

The KEB C6 HMI series is the ideal solution for customers looking to replace or retrofit their Rockwell HMI. The C6 HMI can integrate directly with your current system because of many interfaces and communication drivers for PLC and VFD communication (over 40+ communication drivers to support major protocols).

It also offers direct tag sharing, integrated remote maintenance, and easy-to-use programming software to reduce the costs of development.

This post will focus on how the C6 HMI can integrate directly with your current Allen Bradley PLC, and replace your Allen Bradley PanelView HMI or current HMI.

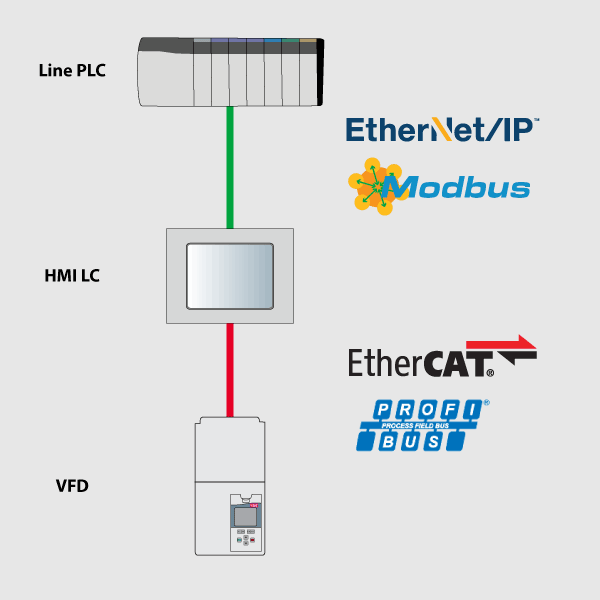

Protocol Support

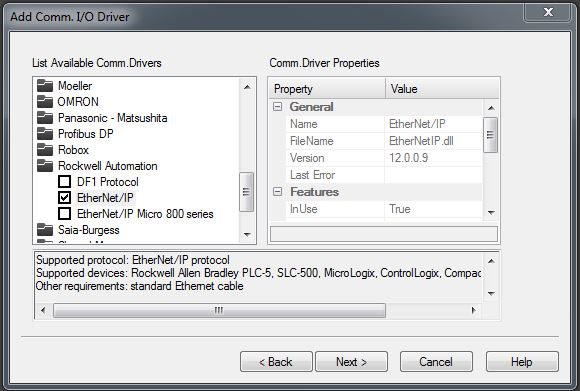

Will the C6 HMI connect and communicate to the Allen Bradley PLC? Yes, to establish communication and support Allen-Bradley Ethernet and Serial protocols, KEB has developed specific EtherNET/IP and DF1 serial communication drivers. All communication drivers can be easily configured during the HMI startup wizard and are free of charge. Below is a list of supported Allen Bradley controllers:

EtherNET/IP Protocol

- CompactLogix

- Control Logix

- MicroLogix

- FlexLogix

- PLC-5

- SLC-500

- Micro800

DF1 Serial Protocol

- CompactLogix

- ControlLogix

- MicroLogix

- Flex Logix

- PLC-5

- SLC-500

Many Interfaces

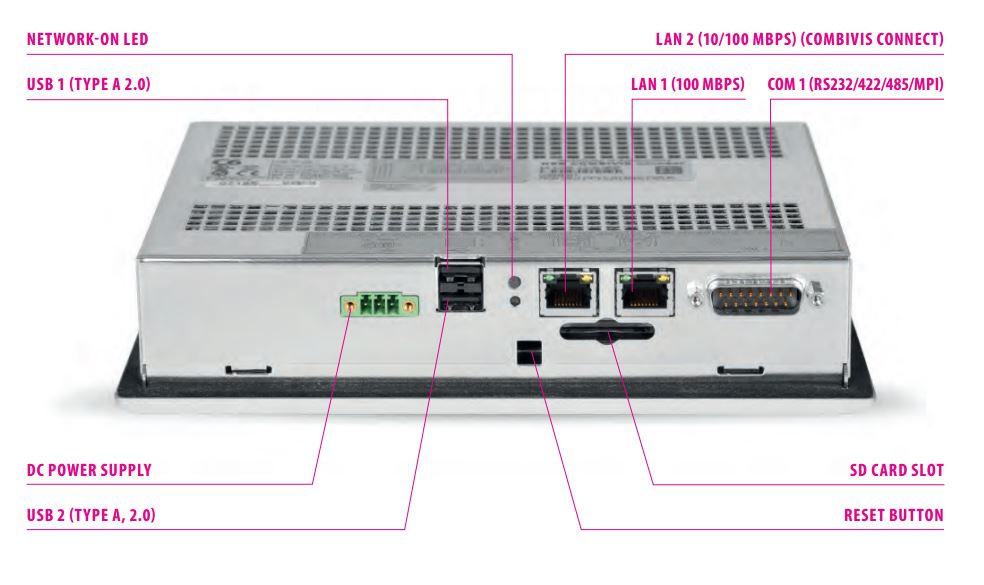

To communicate with your Allen Bradley PLC and entire machine network the C6 HMI is equipped with many interfaces including 2 x Ethernet Ports and 1 x Serial Interface (RS232/422/485). Also included are 2 x USB ports and 1 x SD card slot for file saving and data collection.

Rockwell Tag Import

There is no need to rewrite PLC code or redesign an existing machine. KEB’s tag import functionality allows for seamless tag transferring. All tags from the current Allen-Bradley PLC project can be imported into the KEB HMI software called Combivis Studio HMI.

Screen drawing and configuration are easy with drag and drop design methods as well as an extensive template library for reduced development time.

Effective HMI’s designed to increase productivity and output are possible with built-in functions such as alarms, data loggers, recipe management, messaging (email, SMS), and networking. The HMI can support these powerful features with its fast ARM processor and 4GB of memory for project use.

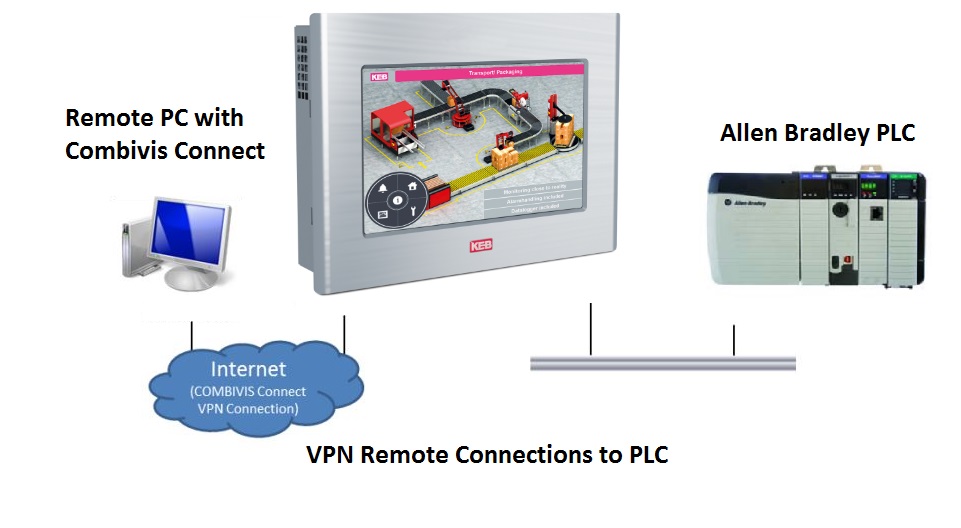

Allen Bradley PLC Remote Connections

Each KEB HMI comes standard with remote maintenance functionality via Combivis Connect. Secure end-to-end VPN connections between a remote user PC and the Allen Bradley PLC or machine network is possible with every C6 HMI.

After logging in to Combivis Connect on the user PC and connecting to the HMI, a virtual Ethernet adapter installed on the user PC by Combivis Connect receives an IP address within the machine network from the VPN server running on the HMI.

At this point, the PC becomes a true member of the remote machine network. This functionality allows for a direct end-to-end connection to your Allen Bradley PLC for programming, data collection, and maintenance from anywhere in the world.

The C6 HMI can replace your PanelView HMI or current HMI and integrate directly with an Allen Bradley PLC. The benefits of the C6 HMI include Allen Bradley protocol support, hardware compatibility, easy programming, and remote maintenance functionality for Allen Bradley PLC remote connections.

KEB HMIs – More Bang for Your Buck

For more information on KEB’s feature-rich HMI products, contact a KEB America engineer today or fill out the form below.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.