Automation Solutions for Motor & Engine Test Stands

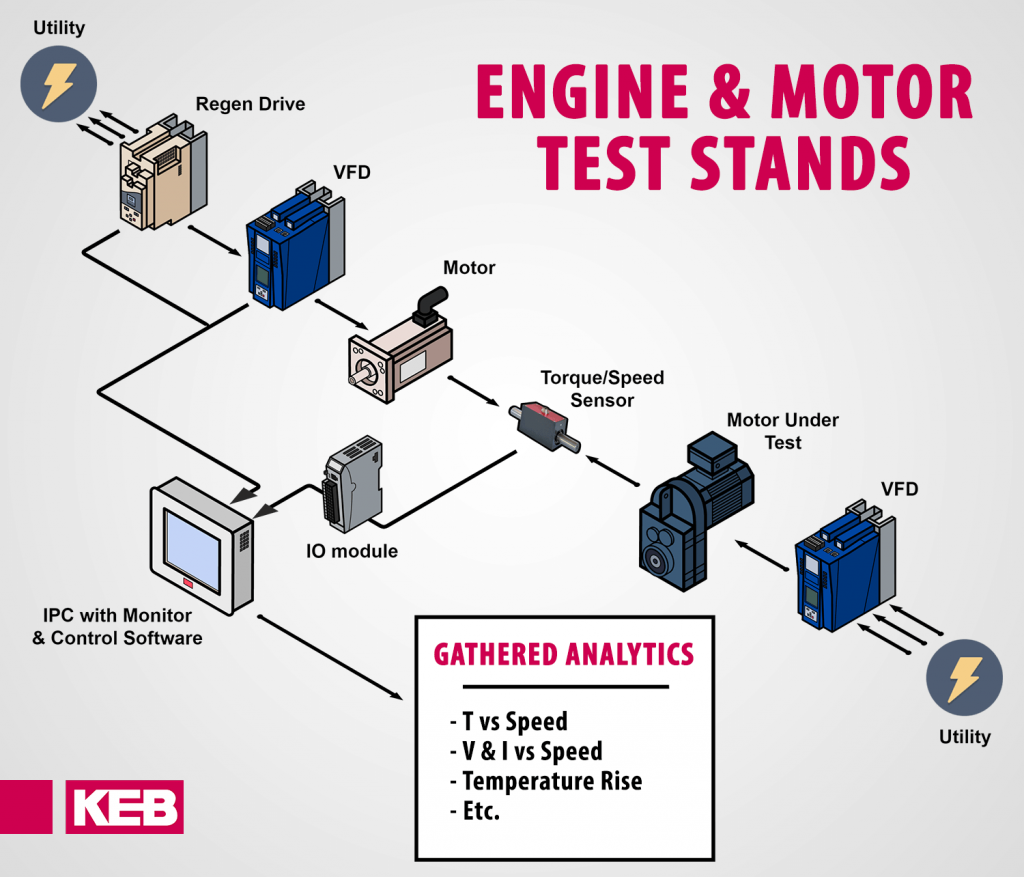

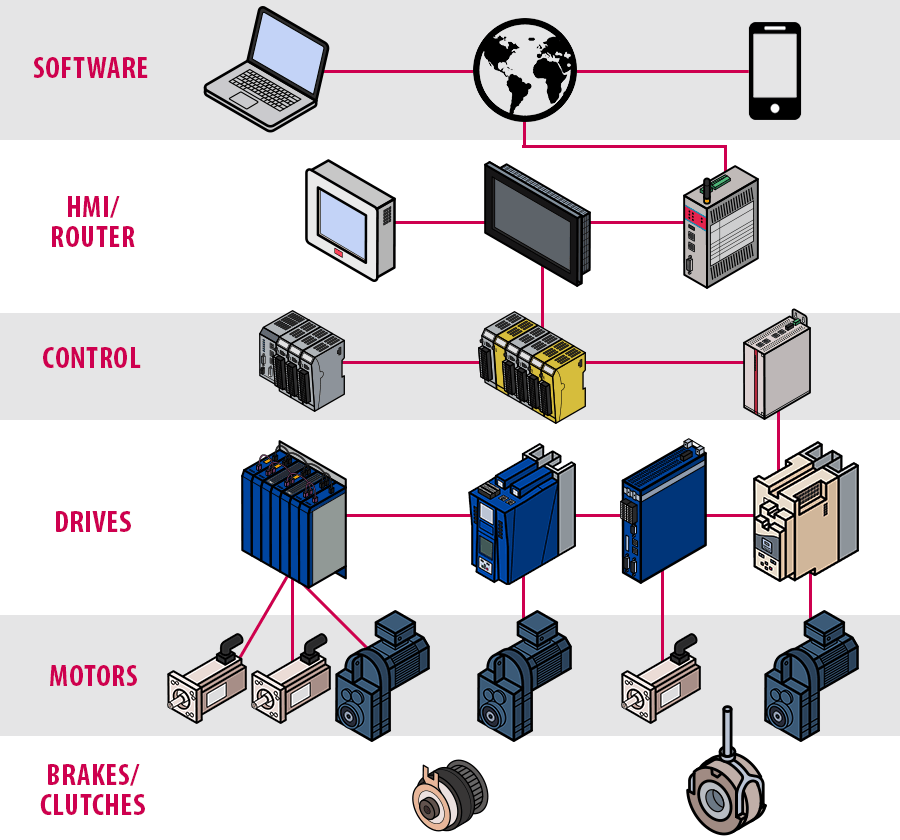

With a full suite of Automation & Drive products and industry-leading performance capabilities, KEB is ideally suited for load cell applications for test stands. From high-efficiency servos for the load motor, to panelized drives for motor control or regenerating energy, all the way to IPCs for the control and monitor of the system, KEB can provide the entire automation solution for the test stand.

System Overview

Engine dynamometer systems are a simple, but effective way to gather a variety of data points of the test engine/motor at multiple operating points. The basic operation requires the test engine to first be ramped up to speed. This test engine is coupled to a load motor that begins unloaded.

Once at speed, the load motor/drive can change the applied load using the torque control in the drive. Throughout the operation, complete load data such as torque, speed, temperature, and power input/output are logged for analysis.

Available KEB Components

The integrated KEB Automation & Drive line of products offers the perfect combination of performance and economics for a full system solution.

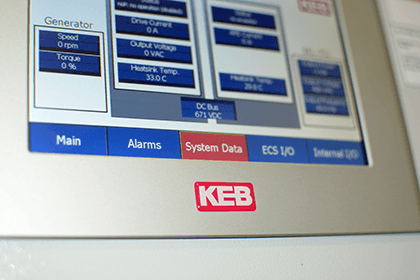

Industrial PC

The highest level control of the system can be achieved with KEB’s line of Panel IPCs. These combine a full HD HMI display and an IPC to control the drives while logging all data feedback. The IPC screens range from 10.1” to 24” and can be selected for resistive or capacitive touch feedback.

The IPCs are equipped with Windows 7 Embedded and are easily programmable using the standardized languages of IEC 61131-3. The Panel IPCs can also be coupled with Remote I/O to support data collection and logging. This could then be exported to Excel or PDF format, in addition to running any automated analysis.

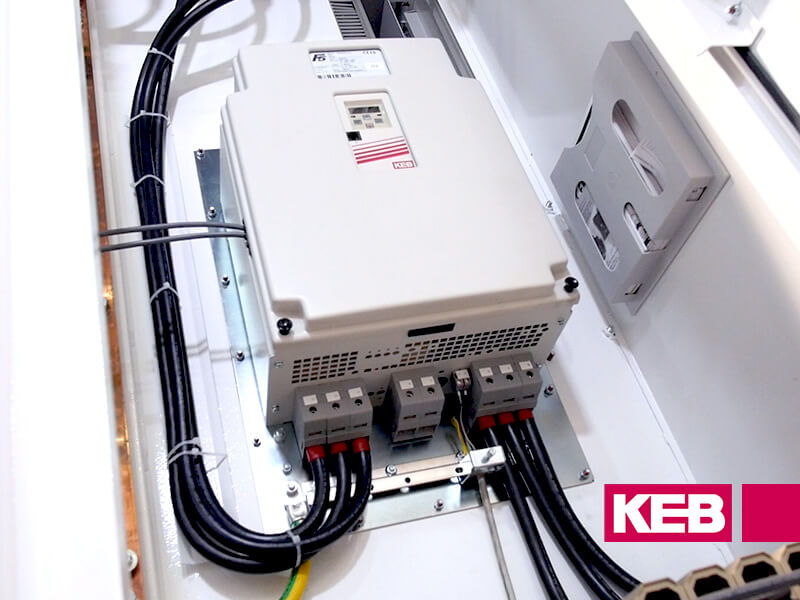

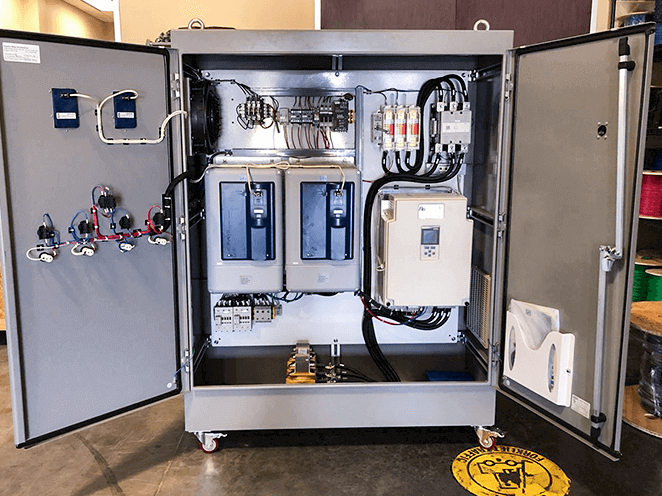

Drives

The control of the motors is achieved using the F5 or F6 series of inverters. Ranging from 0.5-1000Hp and in 230VAC or 480VAC models, these drives can fit in nearly any power range. With modular encoder boards to fit all major feedback types, the drives can provide precise speed or torque control with an easy startup.

Optionally, KEB drives can be supplied in full panelized solutions with appropriate disconnects and filtering.

Servo and Induction Motors

For the load motor, KEB provides a wide variety of induction and servo motors. Induction motors range from fractional to 60Hp, while the more efficient servo motors offer torques up to 90Nm and speeds up to 8000rpm. For higher torque applications, both can be coupled with KEB gearboxes.

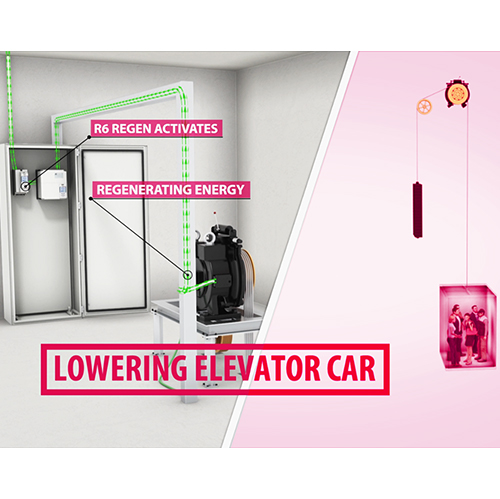

Line Regenerative Drive

Finally, to make the system more cost-effective, KEB offers the R6 line regen unit. Typically motors convert electrical energy into mechanical torque on the output. In the case of the engine dynamometer system, the test engine is generating the torque while the load motor is merely controlling it.

Because of this, the load motor is in a generating operation. That is because it is turning mechanical torque into an output of electrical energy. Using the R6 regen unit, this generated energy can be put back onto the line power. This reduces the system’s net power consumption and thus energy cost.

Unique Benefits of KEB

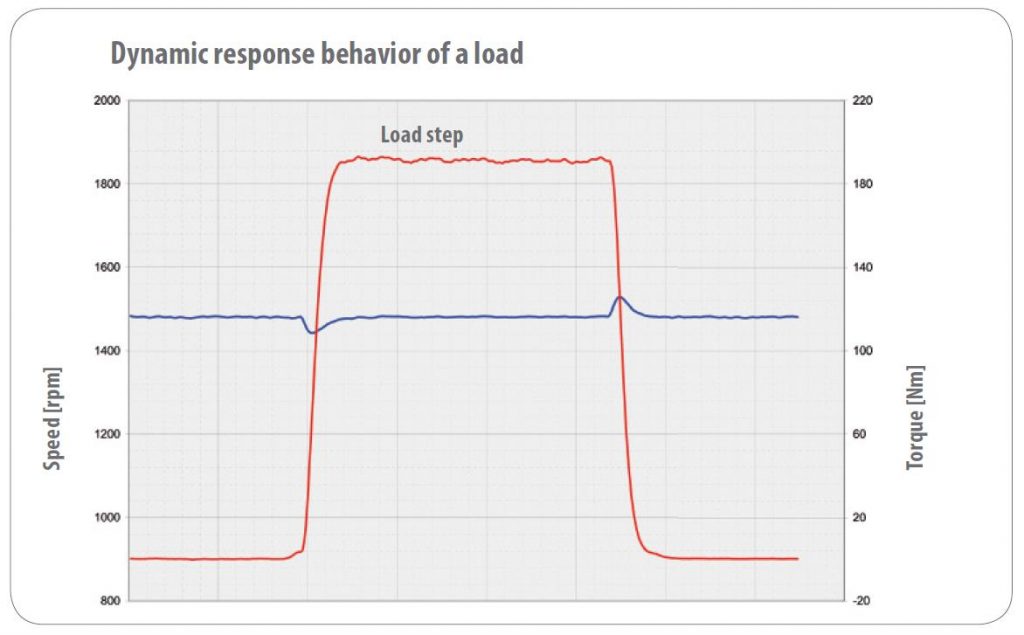

Precise Speed and Torque Control at High Speeds

The F5 drive series is KEB’s staple inverter and offers industry-leading performance. The drive offers closed-loop speed or torque control for exceptional shaft performance in speeds up to 128,000 rpm.

With a 250µs processor update rate, it can react nearly instantaneously to changes; even with load changes as low as 0.3% nominal torque.

Flying Start/Speed Search

Another helpful function of the F5 drive is the speed search or flying start. This allows for the smooth engagement of the VFD with an already running motor, in this case, the load motor. Without the speed search, the motor would be required to stop before the drive is enabled. Stopping the load motor is not possible in this application because it is coupled to the running test engine. With the speed search activated, the current speed of the load motor is determined and that is used as the starting point for the set point speed when the drive engages.

Conclusion

Engine dynamometer systems are an ideal application for KEB’s Automation & Drive products. With industry-leading performance and the flexibility to fit any size or application requirement, the full suite of KEB products can offer the perfect full system solution.

If you’re interested in learning more on what KEB has to offer for engine dynamometer systems, contact an Applications Engineer today.

Do you have a test stand system you are looking to build or upgrade? Let’s discuss how KEB’s full automation solutions can help complete your test stand application.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.