Energy Recovery Systems – Using High Speed Generators to capture Energy

KEB’s Energy Recovery Systems are interesting to highlight because they combine a lot of our unique leading-edge technology. The systems also highlight the breadth of KEB products and our ability to integrate them together to provide a comprehensive turnkey solution.

For the scope of this post, an Energy Recovery System (ERS) or Energy Conversion System (ECS) is an electronic system that controls turbomachinery and converts energy from some process. The process involves converting high-frequency electrical power to something usable on the mains or building power (e.g. 50 or 60Hz). Typical processes could be geothermal, air separation, or waste heat recovery.

Application Overview

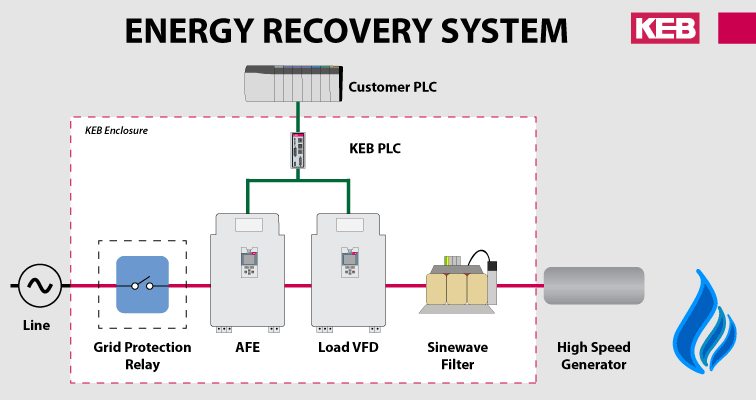

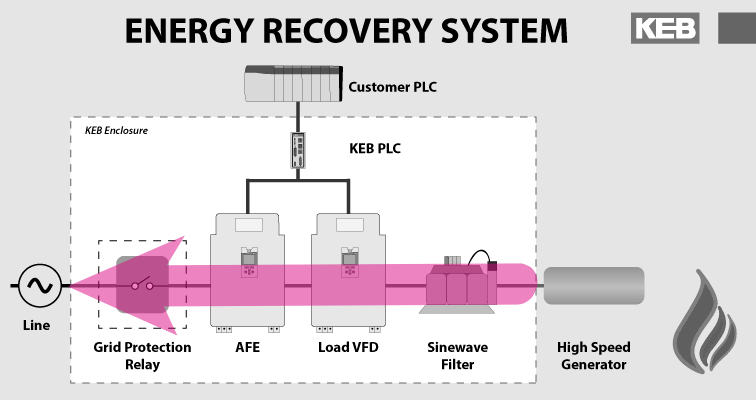

KEB’s Energy Recovery System functions like this. A KEB load drive controls the speed of the generator. The set speed is controlled via a master control system. When the process gas is introduced, the load drive regulates the generator speed. As energy is returned to the electrical system, the Active Front End (AFE) is able to return energy to the building power or utility.

A big highlight of the system is the simple control for the process operator. Rather than trying to regulate the pressure and flow of the process gas, the KEB load drive regulates the generator speed.

High-Speed Turbomachinery

High-speed motor/generator applications are demanding. Control instabilities and imperfections that are masked at low speeds can become critical at high speeds. KEB has a lot of experience running high-speed asynchronous and synchronous generators.

The turbomachinery used in energy recovery processes typically use specialty high-speed generators. The generators are usually equipped with special magnetic bearings or airfoil bearings and can spin in excess of 100,000 rpm. The advantage of using high-speed generators is that they are extremely compact, efficient, and have high power density.

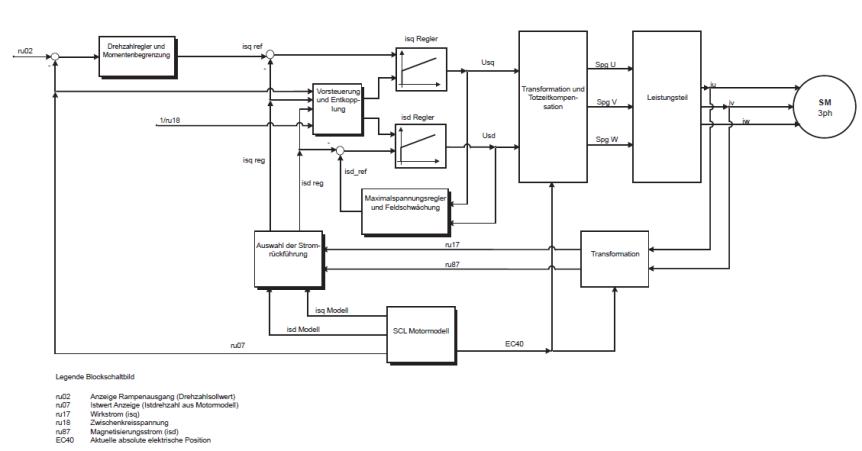

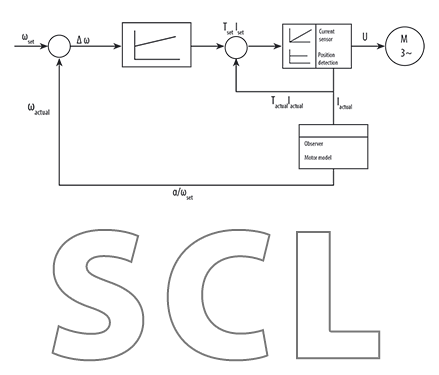

KEB drives are capable of outputting frequencies up to 1600Hz which is required to run these generators/motors. But it is not only the listed output frequency and hardware that separates KEB from other drive vendors. KEB’s SCL™ algorithm provides better speed and torque regulation than commonly used V/Hz control. Another advantage is that SCL does not require encoder feedback – this is difficult to acheive at high speeds.

SCL-optimized generator control creates less rotor heating and increased energy output — this benefits the motor manufacturer and the user.

SCL offers a lot of flexibility with parameter adjustments as well – this allows the KEB system to work with a variety of different generator types and designs characteristics.

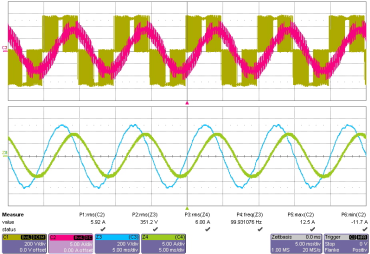

Another reason KEB is well suited for high-speed drive applications is that of our experience designing and supplying sinewave filters. A sinewave filter cleans up the drives PWM output and provides a sinusoidal waveform to the motor winding. This also helps reduce motor heating which is critical to a high-performance system.

Air-Cooled or Water-cooled

KEB offers both air and water cooled drives. Many times, there will be liquid cooling in the system already. Liquid-cooled drives offer a number of advantages especially if the systems will be installed at high altitudes or in high ambient temperatures.

Air-cooled versions are often preferred for their simplicity. The point is that KEB can provide both solutions, depending on the application needs.

High Power – with scalable offerings

The purpose of installing an Energy Recovery System is to lower overall energy usage and save the facility money. This means that smaller systems will likely not provide sufficient ROI and warrant the investment. And at some power threshold, the systems become economically feasible.

KEB does high power well. This means the energy recovery concept can be easily scaled across different power ranges. With optimization, it becomes easier to make a business case for investing in an energy conversion system.

KEB offers Active Front End (AFE) technology with low harmonic distortion (THiD). AFE is of interest to those looking to generate power back to the mains. The clean generated power will not create issues for other electrical loads and the power factor can even be compensated as needed.

Full Panelized System

KEB offers a standalone drive panel that includes all the drive, filter, and control necessary to control the motor-generator.

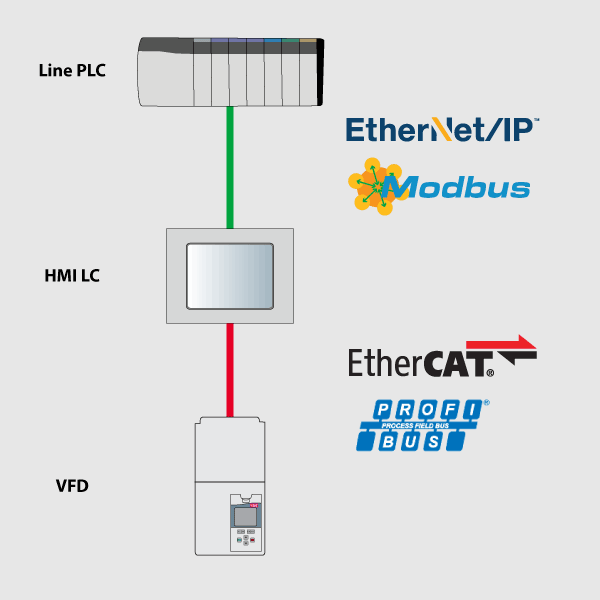

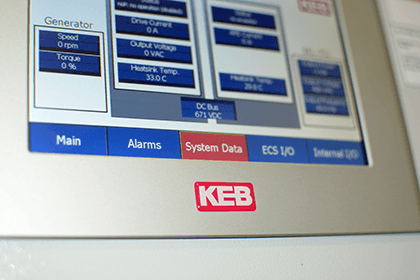

A C6 HMI LC provides drive diagnostics and the ability to make parameter adjustments. The HMIs ship with a CONNECT runtime which means the systems can provide remote access. This gives the possibility to provide remote maintenance and future PLC upgrades.

The HMI LC can also act as a network gateway. This means the KEB panel can tie in with the processes master control via another network protocol like Modbus, EtherNet/IP, or Profinet.

Turnkey Solution

KEB can provide individual components but this is a case where a lot of thought has already been put in and engineered into a complete turnkey solution.

The KEB conversion system includes a grid protection relay and an EMI filter to mitigate high-frequency noise. Also, there is provision to detect an emergency situation and then safely disconnect the system. These are features that would need to be considered and implemented anyway. In this case, they are already engineered by KEB into a system that can be easily integrated into the process and quickly implemented into a customer system.

Contact a KEB engineer today to discuss our Energy Recovery System solutions.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.